1 / 6

Top quality planer cutter knife made in Germany

Get Latest Price

Send Inquiry

| Model No. : | 15*15*2.5 |

|---|---|

| Brand Name : | TIGRA |

Jinhua Qianghong Furniture Machinery Co.,Ltd.

You might also like

Product description

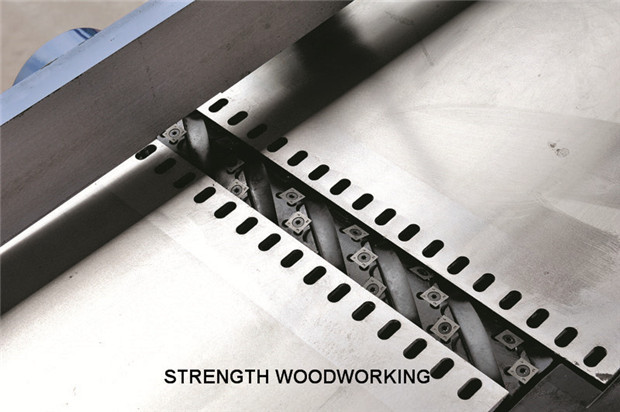

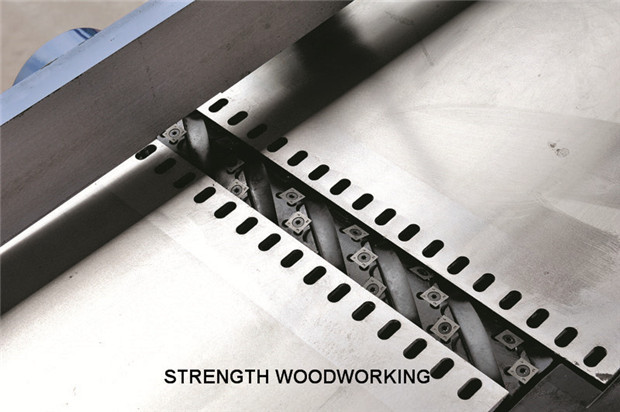

Product Description Planer cutter knife for spiral cutter spindles Specification: 14*14*2.0 15*15*2.5 Brand: TIGRA, made in Germany, the best planer cutter knives TIGRA:As one of the world´s leading manufacturers of tungsten carbide, TIGRA, based in Germany, is offering highest quality tungsten carbide, PCD, PcBN and HSS products: Indexable inserts, saw tips, carbide rods, carbide blanks, carbide wear parts, planer knives, textile and film carbide cutter knives, PCD and PcBN as discs and semi-finished metal working inserts as well as a rapid production of small and large scale carbide products as per your drawing. We are the manufacturer for woodworking machines 40 years and purchase large quantity TIGRA planer blades so now we are the partners and distributors with TIGRA Germany, we can get the best quality and lowest price. Please see the below certificate from TIGRA Germany  Products pictures

Products pictures

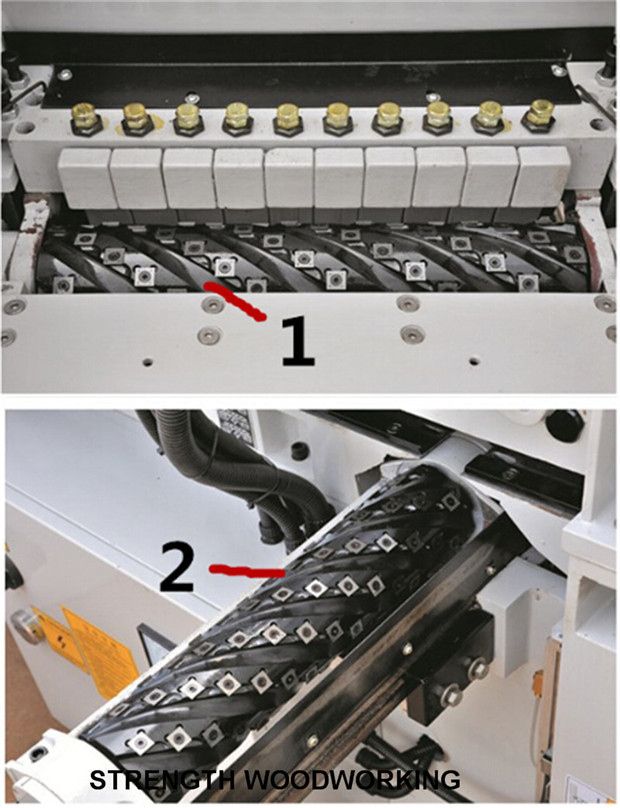

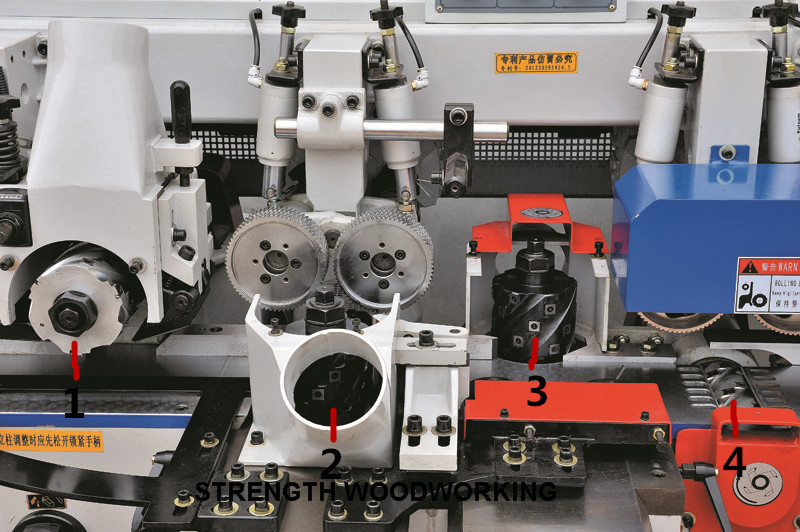

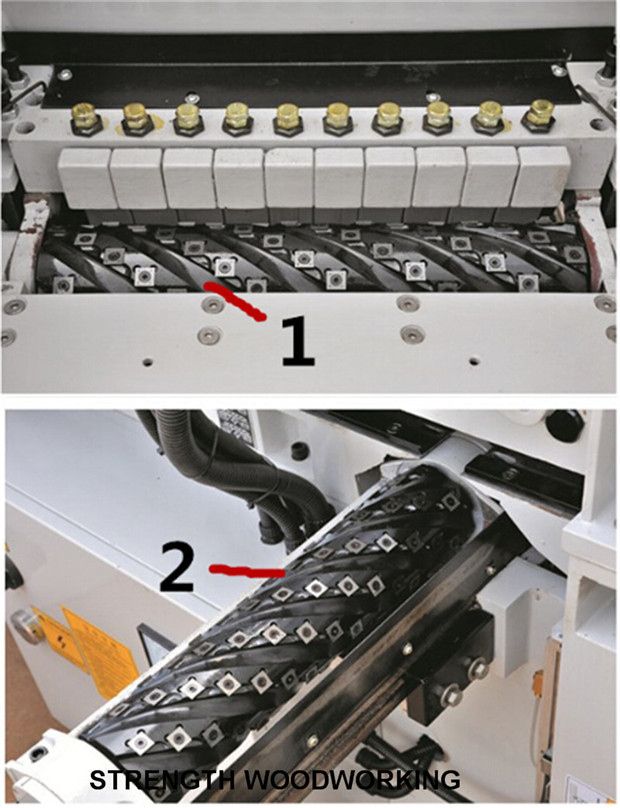

Related Products The planer blades in the spiral cutter

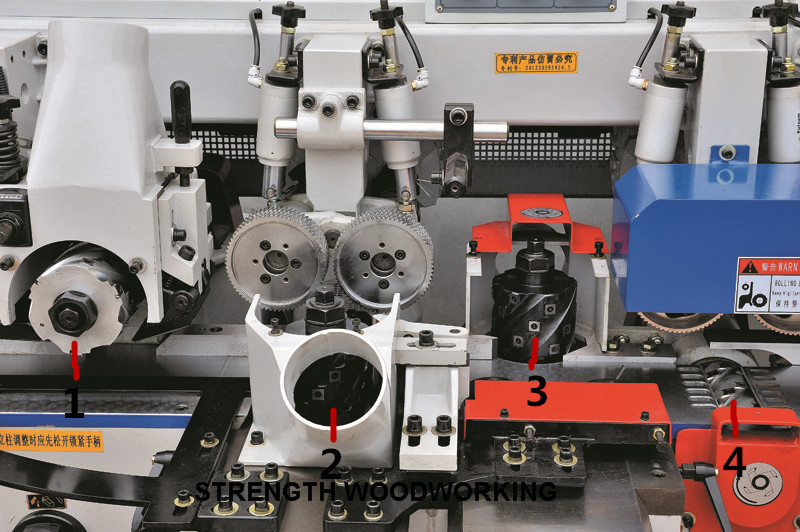

Related Products The planer blades in the spiral cutter  Functions 1, Use in our jointers

Functions 1, Use in our jointers

2, Use in our Single side planer

2, Use in our Single side planer

3, Use in our Double side planer(2 spindles)

3, Use in our Double side planer(2 spindles)

4, Use in our four side planer(4 sindles)

4, Use in our four side planer(4 sindles)

The wood before planing with planer blades

The wood before planing with planer blades  The wood after planing with planer blades

The wood after planing with planer blades  Packaging & Shipping 10pcs/carton box FAQ Question: The notice of knife and blade adjustment Answer: 1. Whether unloading is a blade or blades, please make sure the blade is fixed on the premise of execution.

Packaging & Shipping 10pcs/carton box FAQ Question: The notice of knife and blade adjustment Answer: 1. Whether unloading is a blade or blades, please make sure the blade is fixed on the premise of execution.

2.Every piece of the blade must be by the index finger gently press the blade, the blade is contact with the bottom of the blade, make sure that every piece of the blade after locking, can be on the same circumference of a circle

3.Discharge blade briquetting and the screw, must be 90 degrees wrench and working mesa remove the vertical way, avoid improper damaged blade and the blade holder When assembling heavy cutting spiral cutter, screw end must be below the press block to correct assembly, if the screw end is higher than the briquetting belong to incorrect Question: The difference between Spiral cutter head and Ordinary cutter Answer: 1.Reduce the wood tear

2.After the calibration test of dynamic balance of the cutting tools, more smooth during operation

3.The blade Angle of design, bring high flat cutting, cutting noise reduction and cutting resistance

4.Shorter length of the blade is also great cutting resistance, so the cutting head of motor power demand is relatively low

5.Extend the blades and the use of the mission of the cutting tools

6.Blades and are easy to install to reduce installation time of the cutting tools and machine down time, improve production efficiency

Products pictures

Products pictures

Related Products The planer blades in the spiral cutter

Related Products The planer blades in the spiral cutter  Functions 1, Use in our jointers

Functions 1, Use in our jointers

2, Use in our Single side planer

2, Use in our Single side planer

3, Use in our Double side planer(2 spindles)

3, Use in our Double side planer(2 spindles)

4, Use in our four side planer(4 sindles)

4, Use in our four side planer(4 sindles)

The wood before planing with planer blades

The wood before planing with planer blades  The wood after planing with planer blades

The wood after planing with planer blades  Packaging & Shipping 10pcs/carton box FAQ Question: The notice of knife and blade adjustment Answer: 1. Whether unloading is a blade or blades, please make sure the blade is fixed on the premise of execution.

Packaging & Shipping 10pcs/carton box FAQ Question: The notice of knife and blade adjustment Answer: 1. Whether unloading is a blade or blades, please make sure the blade is fixed on the premise of execution.2.Every piece of the blade must be by the index finger gently press the blade, the blade is contact with the bottom of the blade, make sure that every piece of the blade after locking, can be on the same circumference of a circle

3.Discharge blade briquetting and the screw, must be 90 degrees wrench and working mesa remove the vertical way, avoid improper damaged blade and the blade holder When assembling heavy cutting spiral cutter, screw end must be below the press block to correct assembly, if the screw end is higher than the briquetting belong to incorrect Question: The difference between Spiral cutter head and Ordinary cutter Answer: 1.Reduce the wood tear

2.After the calibration test of dynamic balance of the cutting tools, more smooth during operation

3.The blade Angle of design, bring high flat cutting, cutting noise reduction and cutting resistance

4.Shorter length of the blade is also great cutting resistance, so the cutting head of motor power demand is relatively low

5.Extend the blades and the use of the mission of the cutting tools

6.Blades and are easy to install to reduce installation time of the cutting tools and machine down time, improve production efficiency

Send your inquiry to this supplier

Send Inquiry