1 / 1

Sugar Packing Machine for 1kg Bag

| Brand Name : | Durzerd |

|---|---|

| Types of : | Multi-Function Packaging Machine |

Product description

1kg sugar packaging machine

Brief Introduction:

This sugar packing machine is suitable for the suagr, salt and rice packing in pillow bag at laminated film or single layer PE film. The rice packaging machine is equipped with volumetric cup.

Automatically weighing machine, making bags, filling, sealing, cutting, printing the lot number and cutting easy tearing notches, making continuous sachet, finished product conveying. Applicable for packing 100g-2kg dosing free flowing granule. It could be ideally combined with the Vertical Vfs Packing Machine. If the weight of the package is 15kg or 25kg, it is recommended to use Semi Automatic 15KG Packing Machine and Automatic 25KG Bagging Packing Machine.

Features:

A wide range of pouches: Pillow pouches, gusset bag.

High speed: More than 65 bags/min(laminated film); 40~50 bags/min(single layer film)

Easy to operate: PLC controller and color touch-screen, fault indication on the touch screen.

Easy to adjust: only about 10 minutes to change different pouches.

Frequency control: speed can be adjusted by frequency conversion within the range.

High Automation: unmanned in weighing and packing process, machine alarm automatically when failure.

Safety and Hygiene:

No film, machine will alarm.

Machine alarm and stop when the inadequate air pressure.

Safety guards with safety-switches, machine alarm and stop when the safety guards are opened.

Hygienic construction, the product contact parts are adopted sus304 stainless steel.

APPLICATION:

This sugar packaging machine is suitable for granule products, Such as grains, rice, salt, sugar, tea, seeds, etc. So this machine can also be designed as Salt packing machine and Corn Packing Machine, etc.

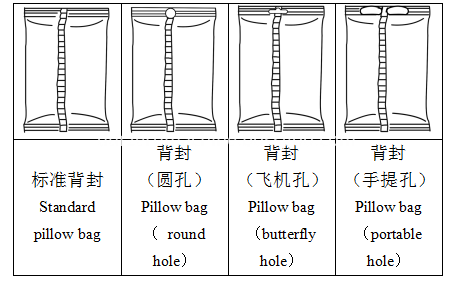

Sample bag type

Options:

Gusset or chain bag device

Perforation device

Impulse sealing Jaw unit for polyethylene

Nitrogen Flushing

Sugar packaging machine Detailed description

Technical Parameters

|

Maximum Capacity |

100-2000g |

|

Speed |

65bags/min(laminated film); 30bags/min(single layer film) |

|

Bag Length |

50 to 340mm |

|

Bag Width |

50 to 200mm |

|

Reel Film Width |

≤420mm |

|

Film thickness |

0.04-0.12mm (40-120mic.) |

|

Reel Outer Dia. |

400mm (15.7in) |

|

Reel Inner Dia. |

75mm (2.9in) |

|

Voltage |

AC380V/50Hz, 3phase or Per customer specification |

|

Power Consumption |

3.5KW |

|

Compressed Air Requirement |

0.6 MPa0.36 M3min |

All ModelsTechnicial information form :

|

Model(Roll film width) |

320 |

420 |

540 |

730 |

920 |

1100 |

1500 |

|

Bag Length(mm) |

80-180 |

80-300 |

80-400 |

100-400 |

150~600 |

200~900 |

200-1000 |

|

Bag Width(mm) |

45-150 |

50-200 |

80-250 |

180-350 |

150~450 |

150~530 |

200~730 |

|

Max Width of Roll(mm) |

320 |

420 |

520 |

720 |

920 |

1100 |

1500 |

|

Packing Speed(bags/min) |

20-55 |

20-80 |

20-100 |

20-100 |

10~90 |

10-80 |

5-50 |

|

Air Consumption(Mpa) |

0.65 |

0.65 |

0.65 |

0.65 |

0.65 |

0.65 |

0.65 |

|

Gas Consumption(m3/min) |

0.3 |

0.3 |

0.4 |

0.4 |

0.5 |

0.5 |

0.5 |

|

Power Voltage (v) |

220v/380v |

220V/380v |

220v/380v |

220v/380v |

220v/380v |

220v/380v |

220v/380v |

|

Power (kw) |

3kw |

2.2KW |

4kw |

5kw |

5kw |

6kw |

6kw |

|

Weight(kg) |

350 |

540 |

600 |

900 |

1000 |

1100 |

1200 |

In Customer Factory

Customer Visiting

Our Service

Pre-sale Service

1. Equipment model selection;

2. According to the special requirements of customers, personalized customized products;

3. Train technicians for customers free of charge;

4. Free professional technical engineers to plan the site on site and design the best process and plan.

5. Acceptance of the product;

6. Assist the client in drafting the construction plan;

Medium-sales Services

Durzerd have the trained team to follow your orders methodically to guarantee the products can be finished on time with high quality.

After-sales Service

1.One Year Warranty,As long as there is a non-human fault in a year,free re-placement parts.

2.Parts Replacement,Don’t worry about the parts damaged or not sold after the machine is sold.we have a field factory with hundreds of enployees to serve you.

3.Engineer Asssignment,Lifelong maintentance,If your equipment breaks down,we will arrange engineers to repair it.

4.Online Instruction,We open online services,as long as your equipment failure,our engineers will be the first time for a one-to-one trou-bleshooting.

5.Feedback Survey,The engineer is required to bring a questionnaire to fill in the satisfaction with the engineer and the use of the equipment.

Send your inquiry to this supplier