Video

1 / 4

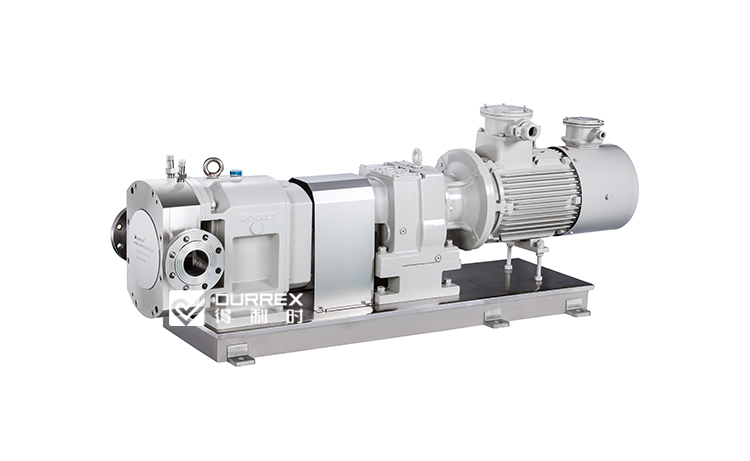

Sucrose transfer lobe pumps in sugar production

$950.00

≥1 Set/Sets

| Model No. : | TLS |

|---|---|

| Brand Name : | DURREX |

| Applicable industry : | Manufacturing Plant,Food &Amp; Beverage Factory |

Ningbo, Zhejiang, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

Sucrose transfer pump--Lobe pump

Cane sugar is another sugar production, also can use lobe pumps to transfer sucrose while production. High viscosity medium, low flowability, so lobe pump withsteam jacket is suitable for this working conditions. On the other hand, mechanical seal with oil lubricant, can extend using life of seal, low maintenace cost while using.

Lobe pump with steam jacket is one of the products specially developed by Durrex, steam jacket method mainly including two type: pump body and pump cover. Steam or hot water can be injected into the pump body or pump cover to keep the working chamber constant temperature. It effectively prevent seal damage caused by material solidification during startup. It can be widely used under the condition that the material viscosity is greatly affected by temperature. It can be used for production process of sugar, chocolate, drugs, butter, and so on.

We are specialized in the production of rotor pumps and homogeneous pumps. The production capacity reaches 18000 units/year. Our pumps can transfer medium with viscosity up to 1,000,000cps, with a maximum flow rate of 400m3 / h (Capacity of 30L / R).

Product features:

1. Gap is kept between the rotors and rotors & pump body, no friction, long using-life.

2. Simple assembling and disassembling, easy to maintenance and clean, less easily-damaged parts.

3. High efficiency and energy-saving, low failure, reliable sealing and low noise.

4. In the same type pump, different type rotor can be interchanged.

5. Capable to pmp the viscous medium from 1cp to 2million cps.

6. Capable of pumping mixture of gas, fluid and solid medium.

7. Equipped with inverter, the flow can be adjusted as requirement of end-user.

8. Flange, screw or clamp connection can be selected as required.

9. Higher hygienic grade, support CIP, SIP. The surface roughness is 0.2--0.8um, got 3A, FDA certification.

10. Hygienic safety valve is built-in structure.

Pump pic for reference:

Twin-Rotary pumps are multi-functional and bi-directional positive displacement pumps, produced with fine technology. The manufacturing engineering and pr

Video

Ningbo, Zhejiang, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier