1 / 5

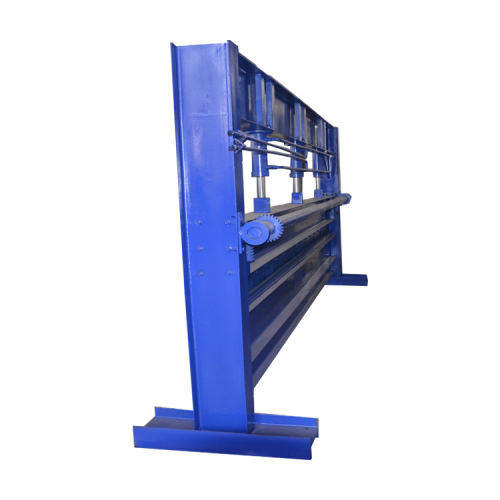

steel coil slitting /sheet coil slitting machine

| Model No. : | ZM |

|---|---|

| Brand Name : | ZHOUMING |

| Forming Speed : | 12-15m/min |

Shijiazhuang, Hebei, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

steel coil slitting /sheet coil slitting machine

Steel coil slitting /sheet coil slitting machine is one kind of Gutter Cold Roll Forming Machine. It can be used to cut steel coil as well as steel sheet. In addition, it can be divided into automatic cutting machine and pedal cutting machine. As a many- year experience factory, we can provide you the best profile as your require. Of course, It is better than you have your own profile drawing. If you are interested in our product, you can contact me.

Technical:

(1) Manual decoiler

Un-powered; Single head;

Max. Capacity: 5000kg;

Coil inner-diameter: 508mm

(2) Roll-Forming M/C:

Roller Material: 45# steel

Voltage: 380V/50Hz

(3) Cutting Mechanism

It adopts hydraulic drive and automatic location to decide the dimention and cut the target products.

Match equipment: One set of cutting tool, one hydraulic tank, one cutter machine.

Stop to cut, Post cut cutting length tolerance: ± 2mm

Cutting tool material: GCr12 with quenched treatment 60-62° C

(4) Hydraulic System

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

Match equipment: A set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

(5) Computer control cabinet:

It adopts Taida PLC to control. The target piece length is adjustable and digit of it can be adjusted

Computed mode has two modes: Automatic and manual one.

(6) Counter:

One counter gauges length, pulses, and decides length

(7) Output table

It used to load the forming plate

Descriptions:

Thickness of material: 0.3-0.8mm

Main structure:300H steel

Wall plate: 16mm

Electric motor power: 4KW

Diameter of shaft: 52mm

Roller: 15rows

Forming speed: 12-15m/min

Material of Rollers: Cr12

Cutting type: Hydraulic shearing

Motor: 380V, 50HZ/3 phase

Hydraulic motor: 3KW

Size of machine: 6.5m*0.6m*1.2m

Warranty: 12 months limited warranty

Delivery: 30 days after receipt of advance payment

Package: Plastic packing and nude in the container

Payment Term: T/T, L/C, Trade assurance

FAQ:

1. Q: Are you a manufacturer?

A:Yes, we are manufacture with roll forming machine factory.

2. Q: How should I do if I would like to order my target machine?

A: Just send us your design drawing if you have. Or tell us your design idea. We arrange our engineer to drawing it for your confirmation.

3. Can you use other brand of spare parts for me if i want?

A: No problem if you want to pay the money.

Detail Images

Packing and Shipping

Contact

Shijiazhuang, Hebei, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier