1 / 1

Standing seam metal roofing roll former

| Brand Name : | maxmach |

|---|---|

| Suitable Raw Materials : | Color Steel Plate |

Hangzhou, Zhejiang, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

This 205 Standing seam metal roofing roll former is the special roll forming machine for steel sheet cold-form industries.Standing seam metal roofing roll former can continuous form the steel sheet according to customer`s requirement, automatically cut to length.

Standing seam metal roofing roll former Technical Parameters

NO Item Para Memo

1 Suitable material Type Color steel

Thickness (mm) 0.4-0.8

Yield Strength (Mpa) 230-300

Width mm) 1250

2 Forming Speed (m/min) 20-25 Not including cutting time

3 Forming main motor power(KW) 3*4 Will be according to actual design

4 Uncoiler hydraulic power 3 Will be according to actual design

5 Hydraulic station power 2.2 Will be according to actual design

6 Total power 17.2 Will be according to actual design

7 Power AC380V,50Hz,3 Phase According to customer

8 Dimension (L×W×H, m) 20×3×2 Will be according to actual design

Standing seam metal roofing roll former Components

Name Model/Name Quantity Technical Description

1.Decoiler system Arm type decoiler 1set Arm-type, hydraulic expanding, hydraulic motor releases the sheet

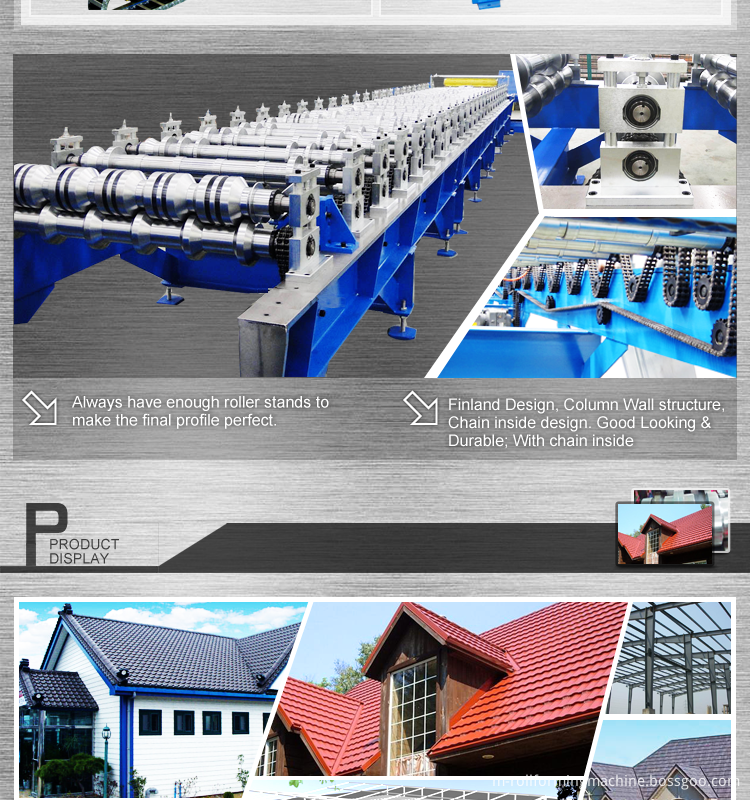

2. Main forming system Feeding guide device 1set 1. Roller material:No.45 steel with surface hard chrome painted.

2. Roller inner supporting structure type: column

3. Motor driving, the back/forward rollers driven by chain, part of upper/lower rollers driven by gear

4. Cutting blade material Cr12 quenched treatment

Roll forming system 1set

Post-cutting device 1set

3. Output system Support table 2 sets For supporting the finished plate, length in 2 meters for each set

4. Hydraulic system 1set Uncoiler and cutting system adopts separated hydraulic station

5. Electric control system 1set 1.PLC Control, encoder automatic cutting in length

2.Operation stage: Touch screen+ button

3.AC frequency for adjusting the speed

Standing seam metal roofing roll former Working process

Decoiler →Guiding system →Roll forming →Cut to length →Output the finished products

Description of all components

A)Arm type automatic decoiler

1. Function and components

Structure Decoiler type Expanding type Press arm Coil car Hydraulic system Electric control system

Arm type Passive Hydraulic No No Separated Shared

2. Parameters

Max loading capacity 5T

Suitable coil ID φ508mm

Suitable material width(max.) 1250mm

3. Main structure type and features

1)Machine frame adopts welding structure with shot blasting treatment

2)By using hydraulic cylinder to realize the function of expanding or decrease the inner diameter of decoiler, and finally realizing the function of tightening the coil.

3)Put the steel coil on the middle part of the mandrel, after that let the hydraulic cylinder tighten the coil. While the machine is started, the hydraulic motor will drive the mandrel at first, then the steel sheet will be released, take the sheet to the forming rollers and it will move automatically while the rollers run. After that, the forming rollers will pull the sheet. All the steel coil will tighten the sheet by its braking resistance.

B)Roll forming system

1. Guide device

Adopting guiding bar and sliding block to control the width and position of the steel sheet. The sheet is guided in the correct position and runs to the roll forming equipment.

2. Roll forming system

Roll forming system consist of machine frame, transmission parts and roll forming rollers etc.

1)Machine frame adopts welding structure with shot blasting treatment.

)The roller of this line is made by high quality no.45 steel, all treated by full CNC precision machines, surface is painted with hard chrome, therefore the roller has good rigidity and level velvet, the sheet made by it has good quality and precision profile.

3)Roller inner supporting structure type: column

4) Cycloidal pin gear speed reducer motor driven, the back/forward roller driven by chain, part of upper/lower rollers driven by gear

5) Adjust the screw bar manually to adjust the distance between upper/lower rollers for difference thickness of sheet.

3. Post-cutting device

1)Adopts post cutting, the cutting blade material is Cr12 with quenched treatment, after cutting, there is no material wasted.

2)Adopts welded frame for good rigidity.

3) The power of cutting is provided by motor.

C)Finished products support table

To support the finished panels. The table we supply are 2 pieces with length of 2000mm.

D) Electric control system

1.Adopts PLC control technology, frequency adjust speed technology, realize the automatic production.

2.System provide good man and machine screen, which can set the bataches, plate length, and quantities.

3.Operation type: Touch screen+ buttton

4.Encoder calculate the number, which has calculation and measure the length function.

5.Adopts MITSUBISH, Frequency.

E)Hydraulic system

1.Uncoiler and cutting system adopts separated hydraulic station

2.Main valve adopts Shanghai Lixin brand.

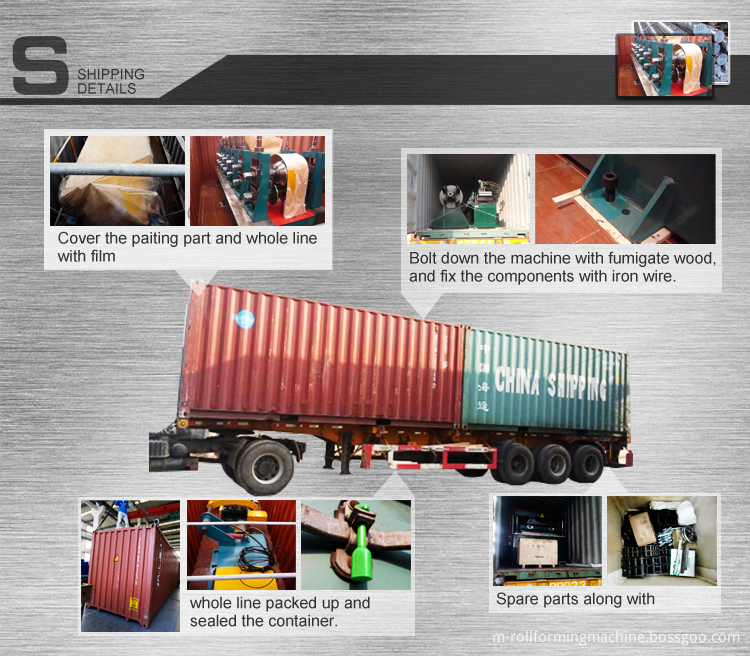

Packing and shipping about the Standing seam metal roof panel machine

Hangzhou, Zhejiang, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier