1 / 1

single layer BOM dryer felt

Get Latest Price

Send Inquiry

| Model No. : | dryer felt |

|---|---|

| Brand Name : | Sinostar |

Ma'anshan Longxin Industry Co.,Ltd.

You might also like

Product description

Specifications single layer BOM dryer felt

1.High dry content.

2.Good dewatering & stability.

3.single layer,BOM type.

4.OEM service.

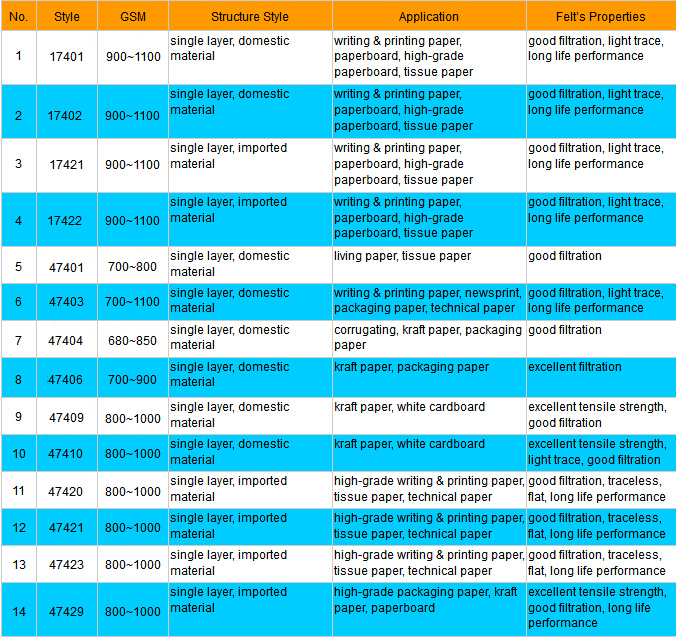

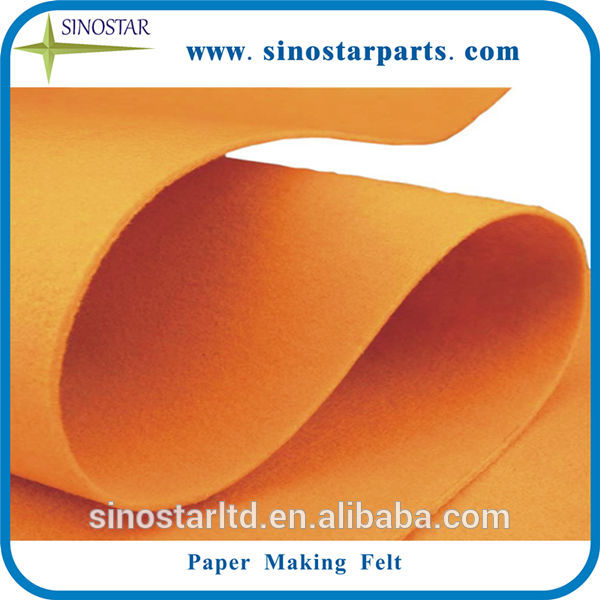

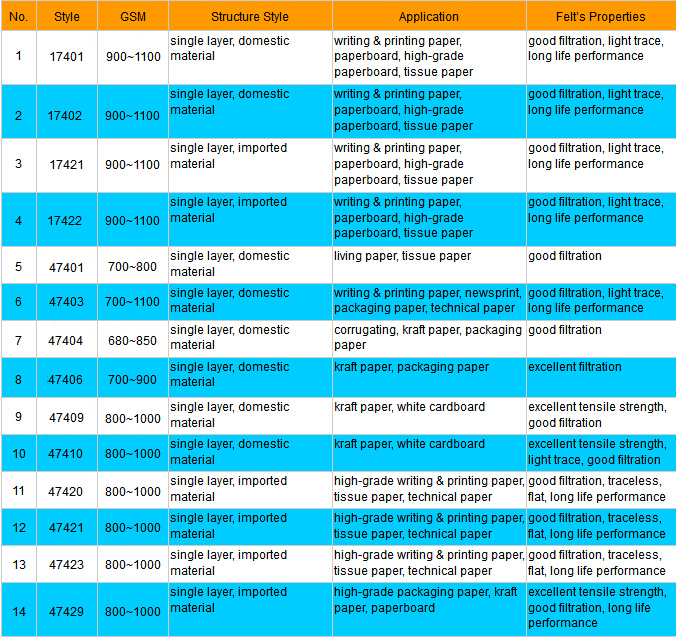

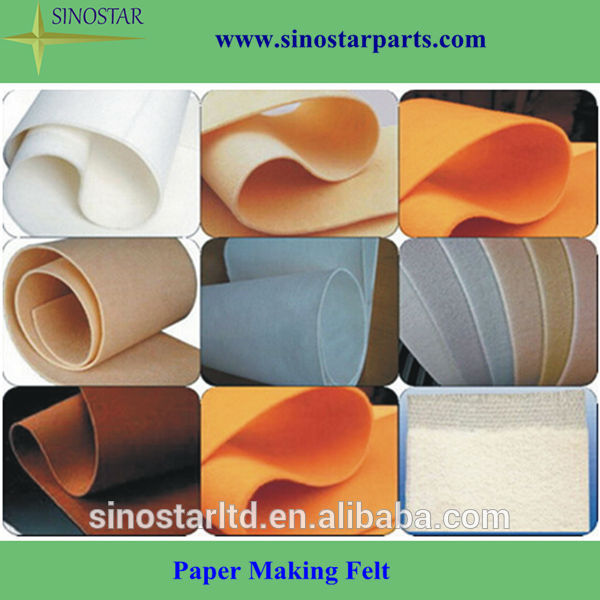

Single layer BOM dryer felt We provide dryer felts and dryer screens including Single Layer, Double Layer, Tri Layer, Chemical Treatment, Paper Making Felt and Pulp Making Felt. Description Single-layer BOM is made of single-layer base cloth layer and fiber layer. The base cloth layer is made of nylon yarn or warp and weft weave by doubling monofilament. The stitch structure designed by different paper machine, different positron and different paper. According the structure of BOM to lay the fiber. Having the characteristics of good filterability, small elongation, easy to wash and clean, light mark, affective to eliminate grain mark and other marks, long life and so on. Widely used for kinds of paper machine to product kinds of paper & paper board.

Single layer Dryer Felt details

Single layer Dryer Felt details

Quality Description High porosity structure. Very good dewatering and stability. Easy to keep clean and washing. Fast start up and run in. Long life time. Good wear resistance. Good void volume to operation. Papermaking felts require the following properties 1.Dewatering ability.(drainability), remove as much water as possible out of wet paper web. 2.Transferability of wet paper web, transfer wet paper web safely to the next position by adhering the wet paper to the felt. 3.Runnability, avoid such undesirable conditions as snaking, deviation, vibration and wrinkling. 4.Wear resistance and hair shdding resistance,avoid wear in short running periods and keep shed fibers to a minimum. 5.Compaction resistance,avoid choking by increasing density and deposition of contaminating substances and maintain resiliency and elasticity in the early running stages. 6.Papaer surface smootheness, avoid anyfelt or roll markings. 7. Break-in, reach the desirable operating speed in the shortest time. 8.Uniformity, achieve a uniform evenness in felts. 9.Simple installation, enable easy felt installation onto the paper machines requiring the least number of people and in the shortest time to finish it. Applications 1.Vibration prone positions. 2.Efficient pressing and excellent sheet transfer. 3.For tissue paper and fast printing paper grades. 4.Apply to improved cylinder vatmachines: 200 - 300m/min. 5. Apply to Imitation BF and Imitation crescent formermachines: 250 – 600m/min. 6.Apply to Imitation BF Series and crescent formermachines: 700-900m/min. Dryer felt product show

For more information, please contact us:

For more information, please contact us:

1.High dry content.

2.Good dewatering & stability.

3.single layer,BOM type.

4.OEM service.

Single layer BOM dryer felt We provide dryer felts and dryer screens including Single Layer, Double Layer, Tri Layer, Chemical Treatment, Paper Making Felt and Pulp Making Felt. Description Single-layer BOM is made of single-layer base cloth layer and fiber layer. The base cloth layer is made of nylon yarn or warp and weft weave by doubling monofilament. The stitch structure designed by different paper machine, different positron and different paper. According the structure of BOM to lay the fiber. Having the characteristics of good filterability, small elongation, easy to wash and clean, light mark, affective to eliminate grain mark and other marks, long life and so on. Widely used for kinds of paper machine to product kinds of paper & paper board.

Single layer Dryer Felt details

Single layer Dryer Felt details | Paper machine: kinds of paper machine. Speed: 500m/min. Paper: 8g/m kinds of Paper. Linear pressure: 100kN/m. Strength: 2000N/5cm. |

For more information, please contact us:

For more information, please contact us:

Send your inquiry to this supplier

Send Inquiry