Video

1 / 5

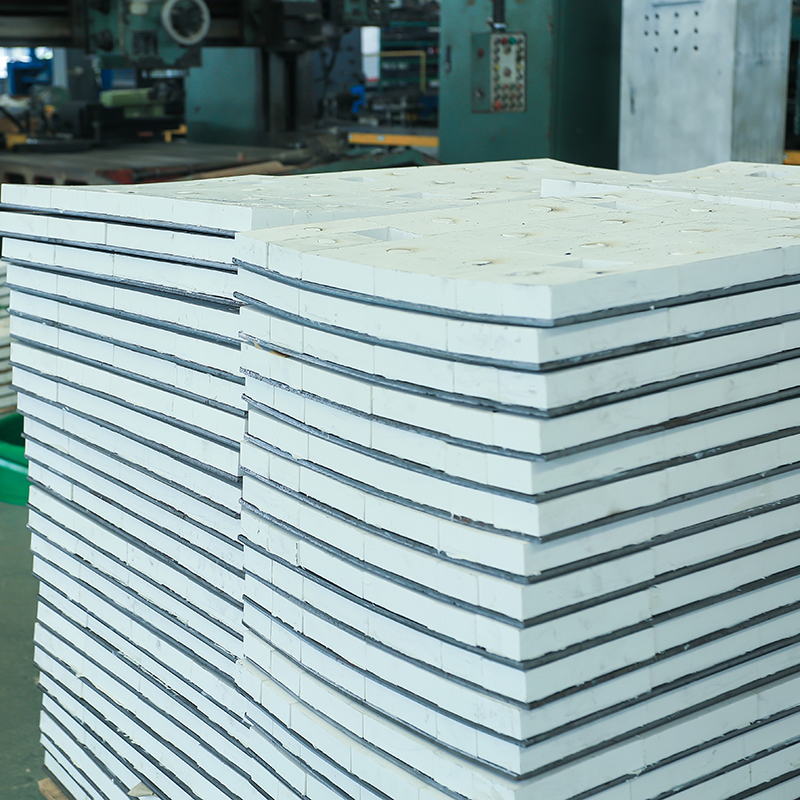

Silo wear and impact resistant ceramic liner

Options:

- Custom made

| Model No. : | Ceramic liner |

|---|---|

| Brand Name : | Tongye |

| size : | Customer needs to customize |

Hengshui, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Platform Certification

- SGS Certification

Product description

Three-in-one ceramic composite lining board is the use of hot vulcanization process to vulcanize wear-resistant ceramics in rubber, and then paste on the inner wall of the equipment through adhesive.Silo Wearing Liners The product has both the wear resistance of ceramic and the impact resistance of rubber. It is suitable for the room temperature material conveyor system equipment to prevent wear, can withstand a certain impact, and does not stick material without blocking material. Ceramic rubber composite liner will vulcanize small blocks of ceramic in special rubber, and use high strength organic binder or bolt to fix the liner in the equipment,PE Engineering Plastics forming a strong anti-wear layer that is resistant to wear and impact. In order to facilitate the installation and replacement of customers, the bolted steel plate and lining plate can also be vulcanized together to form ceramic rubber steel plate integrated vulcanized lining plate.PTFE Engineering Plastics.

Straight - stick lining board, the wear - resistant ceramic sheet pasted on the adhesive paper. When used, the inorganic high temperature resistant adhesive (GWJ-350) is directly pasted on the inner wall of the equipment to form a firm anti-wear layer.

Performance:

Wear resistance: under the same conditions, wear resistance than ordinary pipe 10 times

Corrosion resistance: ceramic lining and inorganic adhesive can resist acid and alkali corrosion

Scour resistance: It can resist the scour of larger granular materials without breaking.

The inner and outer walls are smooth: the smooth surface enables the material to pass freely without the occurrence of hanging and blocking.

Easy installation: convenient transportation, easier and faster installation, can easily erect the pipeline higher; Reduce the load of support and hanger equipment, save the cost of materials and labor;

Reduce maintenance: super wear resistance greatly reduces the maintenance frequency, saving costs and labor costs.

Performance Parameters:

Technical parameters of wear-resistant ceramics

Project Indicators

Alumina content ≥95%

Density 3.6g/cm³

Rockwell hardness ≥80HRA

Compressive strength ≥850MPa

Fracture toughness KIC ≥4.8Mpa.m1/2

Bending strength ≥290MPa

Thermal conductivity 20W/m.k

Coefficient of thermal expansion 7.2x10-6m/m.k

Main technical specifications of rubber used in wear-resistant ceramic and rubber composite lining board

Project name Index

Tensile strength (MPa) ≥12

Elongation at tear (%) ≥250

Shore hardness 55-65

Rupture permanent deformation (%) ≤24

Adhesive force of rubber and ceramic (MPa) ≥3

Temperature resistance ℃ ≤100

Rubber aging age ≥15

Application Field:

Metal smelting (metallurgy), mining, electric power, aggregate, iron and steel, machinery, coal, chemical industry, port terminal, cement, etc. (enterprise's feeding, powder making, ash discharging, dust removal and other machinery and equipment that is easy to wear)

Common applications of ceramic wear-resistant plates are:

• Chute liner

• Conveyor liner

• Cyclone liner

• Hopper liner

• Pipe lining

• Belt pulley lining plate for conveyor

• Chute liner

• Transfer station lining board

• Prevent wet materials from bonding

• Prone to wear and tear in any other applications

Optimal design

We can tailor ceramic wear plates containing specific ceramic sheet specifications, shapes and arrangements to meet the specific wear resistance requirements of the equipment.

We can design and manufacture liner solutions to meet your production objectives according to your exact operating data.

Long service life, reduce the total cost

In many applications, the best wear resistance can be achieved by combining the advantages of other materials and ceramics.

The combination of different materials ensures a long service life compared to other wear resistant products. Superhard ceramic sheets have unique resistance to sliding wear, and the elasticity of other materials, such as rubber, can effectively absorb impact forces.

We can design and manufacture wear-resistant plates of various materials, including ceramic, rubber, metal, polyurethane and a combination of these materials.

High quality products

Ceramic wear-resistant plates are manufactured by Hebei Tongye Technology Co., LTD. Strict quality control procedures are implemented in each stage of research, development, design and production.

This ensures uniform high quality throughout the supply. Precise dimensions and precision tolerances ensure that ceramic wear plates meet your needs.

Video

Hengshui, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Platform Certification

- SGS Certification

Send your inquiry to this supplier