1 / 4

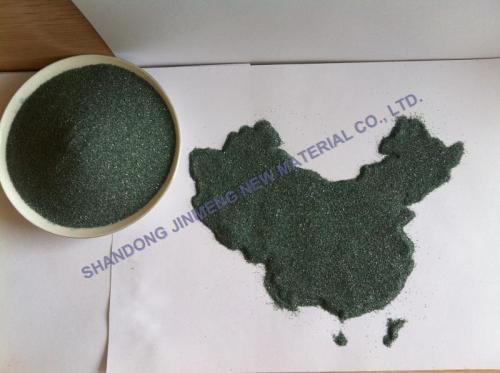

Silicon Carbide grit gree silicon carbide grit black silicon carbide

Get Latest Price

Send Inquiry

| Model No. : | 30# |

|---|---|

| Brand Name : | JinMeng |

Shandong Jinmeng New Material Co., Ltd.

You might also like

Product description

Specifications Silicon Carbide grit

1.Green and Black silicon carbide

2.SiC: 99%min

Silicon Carbide grit Silicon Carbide grit 1.Green and Black silicon carbide 2.SiC: 98%min refractory Silicon Carbide grit is a non-metallic, non-mineral product generated from quartz sand (SiO2) and anthracite coal or petroleum coke(C) under temperature as high as 1,800 degrees Celsius. It can be clarified into black and green silicon carbide depending on the variance of its raw material. Due to its high hardness, low expansion coefficients, ness and good thermal conductivity. It is widely used in abrasives, abrasive cutting electronic products, refractories, special ceramics, foam ceramic, paint, plastics and rubber modified, auto parts, military aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities.

1.Green and Black silicon carbide

2.SiC: 99%min

Silicon Carbide grit Silicon Carbide grit 1.Green and Black silicon carbide 2.SiC: 98%min refractory Silicon Carbide grit is a non-metallic, non-mineral product generated from quartz sand (SiO2) and anthracite coal or petroleum coke(C) under temperature as high as 1,800 degrees Celsius. It can be clarified into black and green silicon carbide depending on the variance of its raw material. Due to its high hardness, low expansion coefficients, ness and good thermal conductivity. It is widely used in abrasives, abrasive cutting electronic products, refractories, special ceramics, foam ceramic, paint, plastics and rubber modified, auto parts, military aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities. aviation , steelmaking deoxidation, etc.

The production standards for silicon carbide sand are Chinese standards, European standards (FEPA) and Japanese standards (JIS).

Our product models manufactured according to FEPA are: F6#,F8#,F10#,F12#,F16#,F20#,F22#,F24#,F30#,F36#, F40#,F46#,F54#,F60#,F70#,F80#,F90#,F100#,F120#,F150#,F180#,F220#,F240#.

Our company can produce a variety of models depending on the different standards, as well as non-standard products and silicon carbide sand. Advantages (1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities.

Purpose | Specification | Chemical Composition(%) | Magnetic material content(%)max | |||

Abrasives grade | SICmin | F.Cmax | Fe2O3max | |||

grain | 12-80 | 99 | 0.20 | 0.2 | 0.0180 | |

90-150 | 98.5 | 0.25 | 0.5 | 0.0150 | ||

180-220 | 97.5 | 0.25 | 0.7 | 0.0120 | ||

micropowder | 240-4000 | 96 | 0.30 | 0.8 | — | |

Send your inquiry to this supplier

Send Inquiry