1 / 1

Servo Motor Driving And Assembly Machine Type Servo Press Assembly Machine

Get Latest Price

Send Inquiry

| Model No. : | XTM-servo |

|---|---|

| Brand Name : | XTM-servo |

Shenzhen Xintaiming Machinery Equipment Co., Ltd.

You might also like

Product description

Specifications Precise reappearances

Suitable for the press-fitting depth control

Flexible action by free motion

Low noise and low vibration

Servo Motor Driving And Assembly Machine Type Servo Press Assembly Machine Product Description

Servo motor driving servo press assembly machine is a new type servo press for high accuracy assembly work.

Highlight of high precision servo presses assembly machine 1.Compared to the traditional pneumatic press and hydraulic presses, more than 80% of energy-

saving, more environmentally friendly and safe, can meet the requirements of clean room equipment.

2.Connected to your computer through the external ports, press-fit data can be stored on your computer, ensure that the processing data can be traced back, ease of production and quality management control.

Functions of human-computer interface The functions and working interfaces which can be fast switched of the color touch screen controller are as below: parameter setting monitoring of I/O

parameter setting monitoring of I/O  current curve production data statement

current curve production data statement  data Technical Parameter

data Technical Parameter

CNC servo press type servo press for assembly

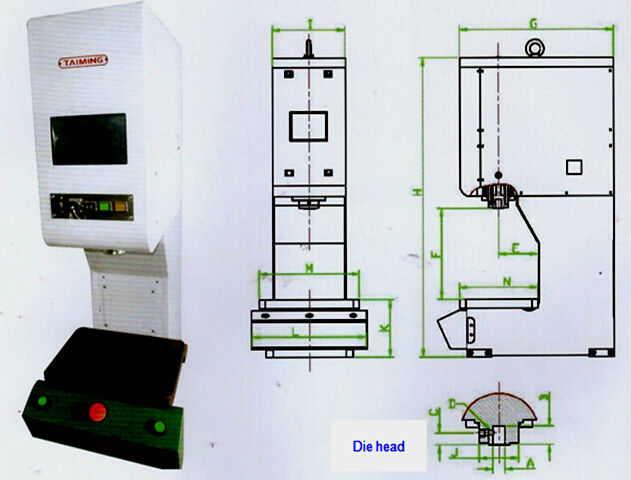

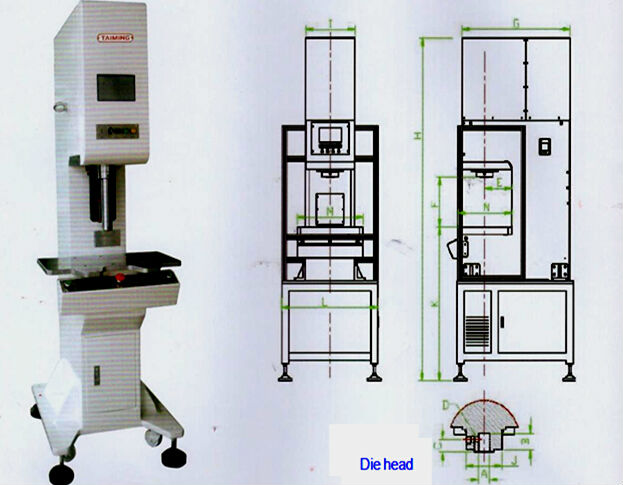

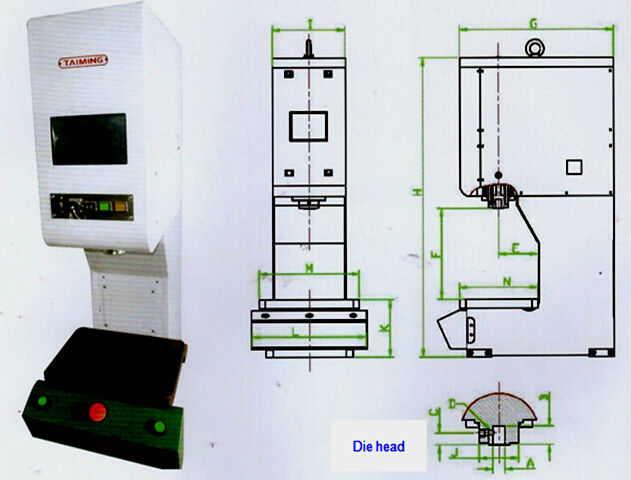

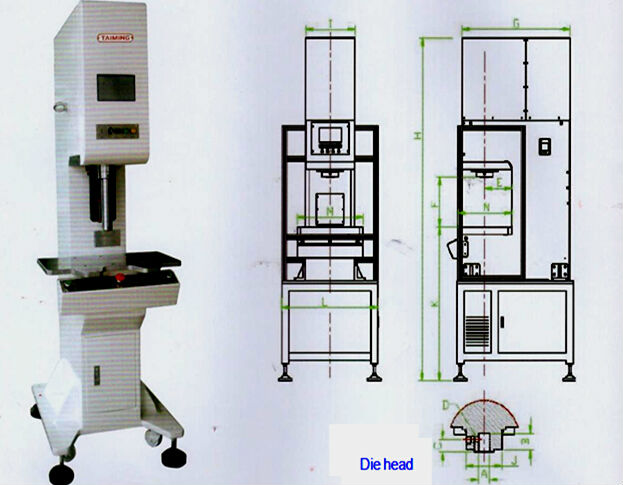

Dimension Dimension of precision servo presses XST desk-type

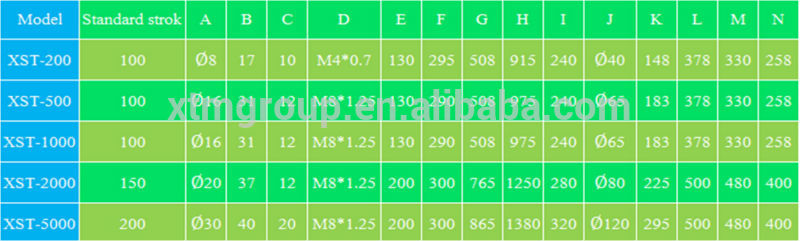

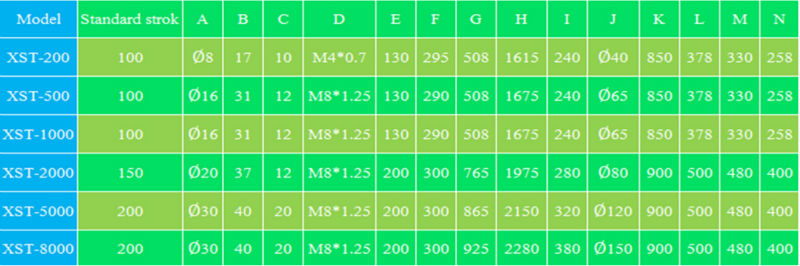

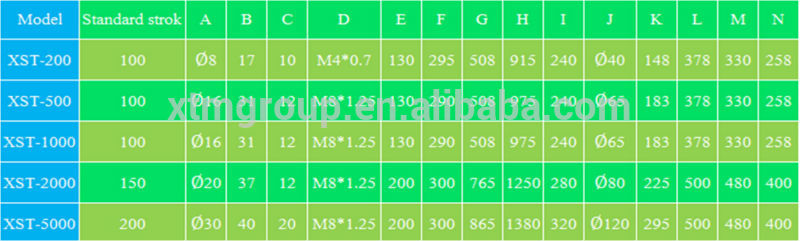

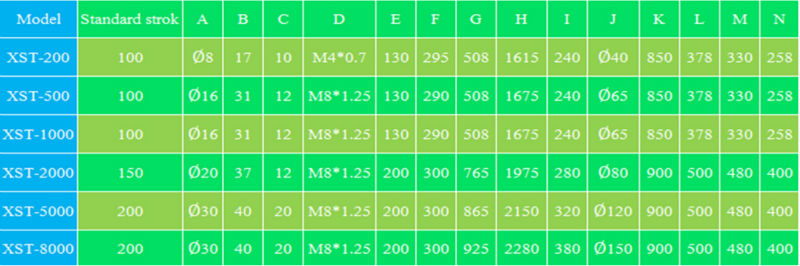

Dimension of precision servo presses XST floor-type

Dimension of precision servo presses XST floor-type

Shenzhen Xintaiming Machinery Equipment Co., Ltd

Shenzhen Xintaiming Machinery Equipment Co., Ltd

Shenzhen Xintaiming Machinery Equipment Co.,Ltd ,the leading company of air and hydraulic press

in China. We have sold our hydraulic press machines to Germany, Hungary, Russia, India, Indonesia, Thailand,

Vietnam, USA, Mexico, Brazil, Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more

than 20 countries.

X.T.M Advantage

Workforce & Facility

7500sq meter manufacturing facility, moe than 150 full time employees , X.T.M is fully capable of

handling the growing demand worldwide, and offering excellent technology, solid qualit at highly competitive prices.

Quality Assurance

Exibition & Visit  Cooperative Partners

Cooperative Partners

Suitable for the press-fitting depth control

Flexible action by free motion

Low noise and low vibration

Servo Motor Driving And Assembly Machine Type Servo Press Assembly Machine Product Description

Servo motor driving servo press assembly machine is a new type servo press for high accuracy assembly work.

| 1. Servo motor driven high-precision ball screw for precision assembly work. 2. Precise closed-loop control of pressure and displacement . 3. Entire process graphs of Press-fit force and displacement can be displayed on the LCD touch screen. 4. Automatically determines the eligibility of product in any stage of the press process,100% removes defective products in real time, enabling online quality control. 5. All technical data (pressure, displacement, press speed, dwell time) can be set via frendly man-machine interface, easy to operate. 6. 100 of different kinds of press-fit programe can be stored. 7. Seven kinds of press-fit models to choose to meet the requirements of different processes. 8. Simply callout the different mounting program to meet the process of different specification product, easily implement a multifunctional and flexible set of lines. |

Highlight of high precision servo presses assembly machine 1.Compared to the traditional pneumatic press and hydraulic presses, more than 80% of energy-

saving, more environmentally friendly and safe, can meet the requirements of clean room equipment.

2.Connected to your computer through the external ports, press-fit data can be stored on your computer, ensure that the processing data can be traced back, ease of production and quality management control.

Functions of human-computer interface The functions and working interfaces which can be fast switched of the color touch screen controller are as below:

parameter setting monitoring of I/O

parameter setting monitoring of I/O  current curve production data statement

current curve production data statement  data Technical Parameter

data Technical Parameter CNC servo press type servo press for assembly

| precise servo press | 200kgf | 500kgf | 1000kgf | 2000kgf | 5000kgf | 8000kgf | |

| work temperature | 0-40°C | ||||||

| Main cylinder stroke | AC220V single phase | AC380 three phase | |||||

| press mode | constant press speed, precise position control | ||||||

| constant press speed, precise pressure control | |||||||

| constant press speed, precise displacement control | |||||||

| press mode | 100 kinds of press mode | ||||||

| human-computer interface | 65536 Colors, 7Inch Touch Screen | ||||||

| control mode | 100Mbps high speed communication module, PLC+exclusive control unit | ||||||

| drive mode | precise AC servo motor, 7 class well ground ball screw | ||||||

| I/O interface | USB2.0, down load & upload available | ||||||

| die connector dia. | ∅ 8mm | ∅ 16mm | ∅ 16mm | ∅ 20mm | ∅ 25mm | ∅ 30mm | |

| pressure output | nominal force | 200kgf | 500kgf | 1000kgf | 2000kgf | 5000kgf | 8000kgf |

| range of application | 10%,100% of the entire stroke | ||||||

| unit | 0.1kgf | ||||||

| pressure precision | 1%F.S | ||||||

| repeat duration | 1‰ F.S | ||||||

| displacement/stroke | standard Stroke | 50/100mm | 150/200/250mm | ||||

| unit | 0.001mm | ||||||

| repeat duration | 0.01mm | ||||||

| linear speed | fast forward | 0.1- -160mm/s | 0.1- -200mm/s | ||||

| detect | 0.1- -20mm/s | 0.1- -30mm/s | |||||

| press | 0.1- -35mm/s | 0.1- -50mm/s | |||||

| return | 0.1- -160mm/s | 0.1- -200mm/s | |||||

| dwell time | Max. | 99.9sec | |||||

| reccomended | <10sec | ||||||

| factory reset | 0.1sec | ||||||

Dimension of precision servo presses XST floor-type

Dimension of precision servo presses XST floor-type

Shenzhen Xintaiming Machinery Equipment Co., Ltd

Shenzhen Xintaiming Machinery Equipment Co., Ltd

Shenzhen Xintaiming Machinery Equipment Co.,Ltd ,the leading company of air and hydraulic press

in China. We have sold our hydraulic press machines to Germany, Hungary, Russia, India, Indonesia, Thailand,

Vietnam, USA, Mexico, Brazil, Italy, Saudi Arabia, Bahrain, South Africa, Australia, Iran and so on more

than 20 countries.

X.T.M Advantage

|

Key aspects of the X.T.M success are:

|

7500sq meter manufacturing facility, moe than 150 full time employees , X.T.M is fully capable of

handling the growing demand worldwide, and offering excellent technology, solid qualit at highly competitive prices.

Quality Assurance

|

Cooperative Partners

Cooperative Partners  Strong research and development ability, powerful marketing ability, commitment, expertise and dedication. When it comes to hydraulic press machines or pneumatic press machine, Please feel no hesitation to contract with X.T.M. |

Send your inquiry to this supplier

Send Inquiry