1 / 5

Scan Vibro Vibratory Feeder Machine

| Model No. : | ZSW-490×110 |

|---|---|

| Brand Name : | We can provide you need |

| Type : | Electromagnetic Vibrating Feeder |

Harbin, Heilongjiang, China

- Manufacturer

- Trade Company

- Platform Certification

- SGS Certification

- Online Expo

Product description

Scan Vibro Vibratory Feeder Machine

Product Introduction

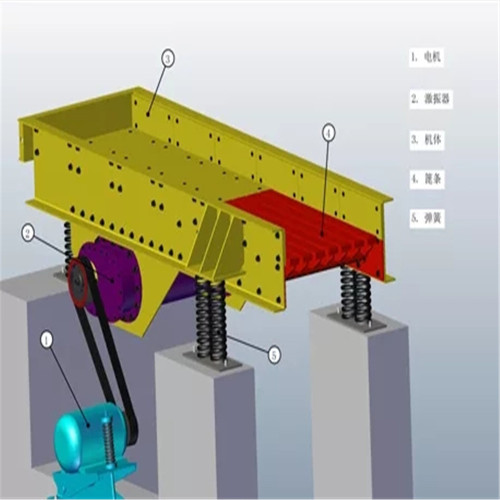

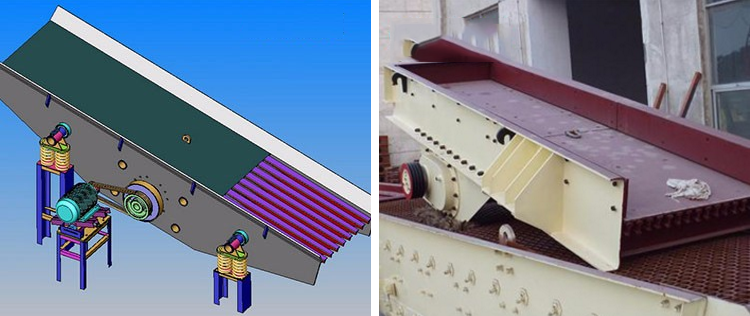

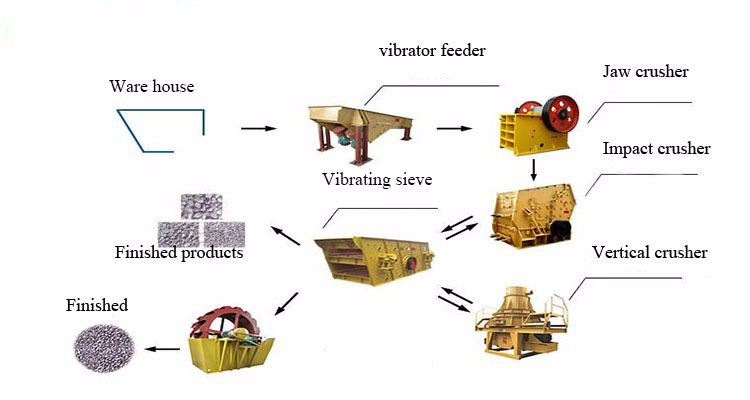

ZSW Series Vibrating Feeder is designed based on principle that spinning of two synchronous eccentric shafts producing vibrating force. It`s mainly used for continuous feeding before coarse crushing, at the same time, screening the materials according to the preset bars gap to improve the crushing efficiency. The feeder is widely used for feeding and crushing processing work of industrial mineral raw material and several kinds of rocks in building aggregate production, metallurgy, mine, building material, chemical industry and many other industries.

Features of Vibrating Feeder

1.ZSW series Vibrating Feeder is designed by the principle that eccentric axis produces exciting force and mainly used for the feeding of primary crusher.

2.Stable vibration, even and continuous feeding to avoid system halted and service life of machine is extended.

3.Pre-screen fine materials while feeding to improve crushing efficiency.

4.Grid bar gap can be adjusted to avoid material blocking.

5.Adjustable speed motor is optional. It is no need to frequently start motor.

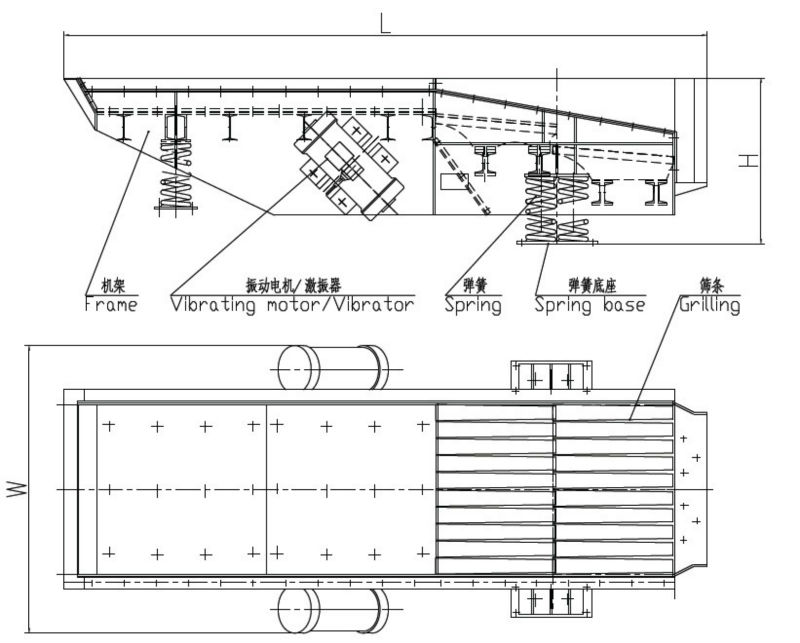

Working Principle: gravel vibrating feeder consists of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator is made of two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. Through drive of the motor, the two eccentric shafts start rotating to produce a linear huge power which forces the feeder to vibrate. Through the vibration, The materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller parts will fall down, avoiding the further crushing, so screening purpose can be reached.

Technical Parameters of Vibrating Feeder

| Model |

Hopper Size (mm) |

Max. Feed Size (mm) |

Production Capacity (t/h) |

Eccentric Shaft Rotation Speed (r/min) |

Motor Power (t) |

Weight (t) |

Overall Dimension (mm) |

| GZD-250×75 | 2500×750 | 300 | 50-80 | 1.5×2 | 1.29 | 2580×1430×600 | |

| GZD-300×90 | 3000×900 | 450 | 80-100 | 3.0×2 | 2.96 | 3050×1430×1550 | |

| GZD-370×100 | 3700×1050 | 500 | 100-150 | 3.7×2 | 3.7 | 3980×1878×866 | |

| GZD-490×110 | 4900×1100 | 580 | 120-280 | 5.5×2 | 4 | 5200×1900×950 | |

| GZD-500×120 | 5000×1200 | 600 | 200-400 | 5.5×2 | 5.2 | 5450×2000×900 | |

| ZSW-380×96 | 3800×960 | 500 | 100-160 | 500-720 | 11 | 4.21 | 3882×1684×1340 |

| ZSW-490×110 | 4900×1100 | 580 | 120-280 | 500-800 | 15 | 5.41 | 4957×1841×1365 |

| ZSW-590×110 | 5900×1100 | 600 | 200-350 | 500-800 | 22 | 6.05 | 6000×1841×1365 |

| ZSW-600×130 | 6000×1300 | 600 | 400-560 | 500-800 | 22 | 7.5 | 6028×2580×2083 |

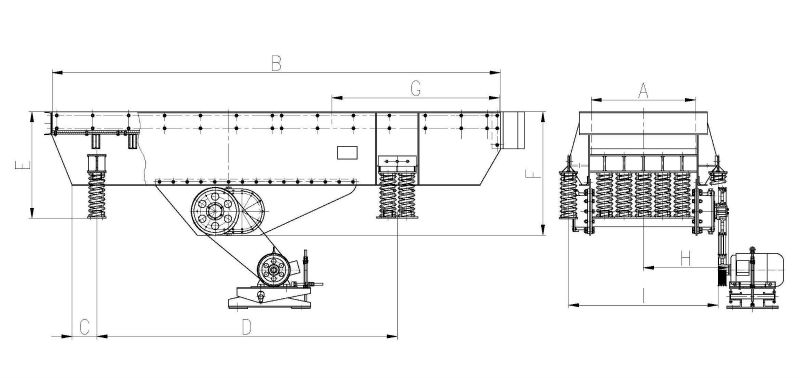

GZD Vibrating Feeder Series Structural Drawing

Package&Shipping

Successful Case

Company Information

Harbin Zephyr Trading Co.,Ltd locates in the north of China, province Heilongjiang,city Harbin.This is an international trading company mainly exports large road machinery such as:asphalt mixing plant,concrete mixing plant,crushing and screening production line and Excavator,Loader,Bulldozer,Truck Crane ,Concrete mixer truck,Dump Truck,Asphalt Paver ,Asphalt rolling machine etc construction machinery and so on...

As one of the first professional supplier of asphalt mixing plant and concrete mixing plant in China,we have always given attention to maintaining our higher level quality control and service , and we have received the ISO9001,CE,SGS etc certificates.Our equipment has exported to 35 countries,including:Russia,India,Bangladesh,Ghana etc.

If you have any inquiry about the concrete mixing plant ,asphalt mixing plant ,stone crusher plant or constructions machinery,please fell free to contact us,We are always warmly welcome you to come and look forward to our meeting!

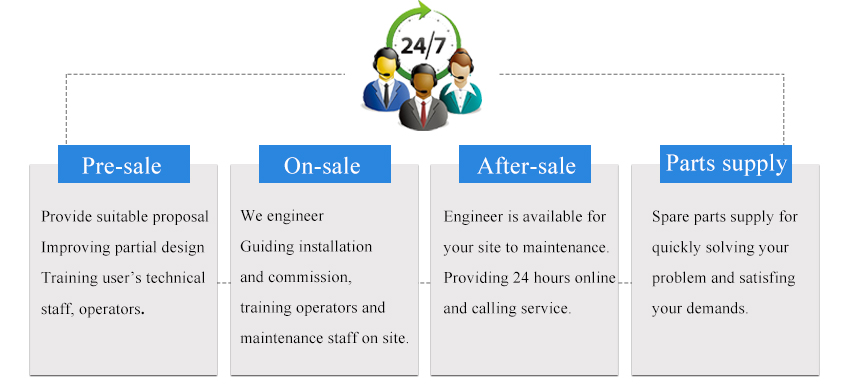

Our Service

1.Design most suitbale flow chart and layout freely according to your request.

2.Provide operating instruction and relative drawing.

3.We can send 1-2 technicians to the site for guiding the installation and commissioning.

4.We offer training service for free.

5.We offer the components with favorable price.

6.Lifetime Warranty.

FAQ

Q: How about the quality of your vibrating feeder?

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.

Q: How about the price?

A: We are as leader supplier, and we can give you lower price than those other companies. Besides, customers can get a discount.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Can you test our samples?

A: Yes. You can send your samples of vibrating feeder to us for test and analysis.

Q: Do you provide beneficiation flow chart of vibrating feeder?

A: Yes. Our experienced engineers are specialized in designing process flow for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore, lead zinc ore, manganese ore, etc.

Contact Us

Harbin, Heilongjiang, China

- Manufacturer

- Trade Company

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier