1 / 4

rapid prototype 3d printing service

Options:

- Custom

| Types of : | Rapid Prototyping |

|---|

Ningbo, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Product description

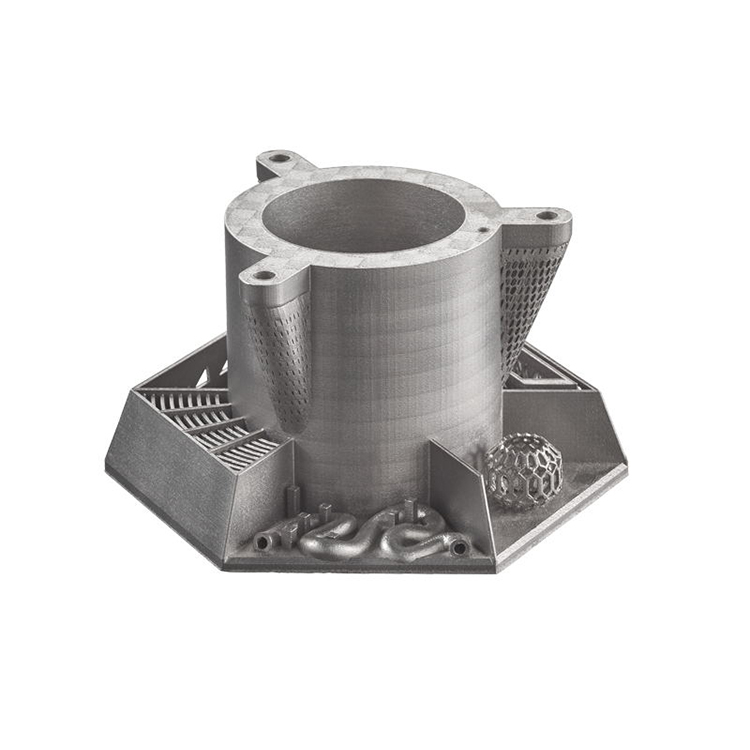

Industrial FDM 3D printers mainly use engineering plastics (ABS, Polycarbonate (PC) or Ultem). These materials often contain certain additives that alter their properties and make them particularly suitable for specific industrial needs (eg high impact strength, thermal stability, chemical resistance and biocompatibility). Some materials printed with industrial FDM have material properties similar to injection molded parts and are generally "good enough" for creating functional end parts. The high-temperature properties of these materials also mean that they are suitable for mold printing for low-run injection molding.rapid prototype 3d printing service

METAL 3D PRINTING - SLM / DMLS

The two technologies have many similarities: both use laser scanning and selectively fuse (or melt) metal powder particles, glue them together and build them layer by layer. Similarly, the materials used in both processes are granular metals.

The difference between SLM and DMLS is due to the basis (and patents) of the particle bonding process: SLM uses metal powder with a single melting temperature and completely melts the particles, while in DMLS, the powder is composed of materials with variable melting points at high temperatures Fusion at the molecular level.

Bering 3D provides 3D printing services for various metal materials such as stainless steel, die steel, titanium alloy, aluminum alloy, and bronze.

SELECTIVE LASER SINTERING - SLS

In the printing process of the SLS equipment, a high-power laser is used to fuse small particles of plastic powder into the required three-dimensional shape. The laser selectively fuse powder materials by scanning the three-dimensional data section on the surface of the powder bed. After scanning each section, the powder bed is reduced by a layer of thickness, a new layer of material is added to it, and the selective laser sintering process is repeated until the part is completed.

SLS 3D printing can be used not only for the prototype design of functional polymer components, but also for small production runs because it has high design freedom, high precision, and produces parts with good and consistent mechanical properties.

STEREO LIGHT CURING MOLDING - SLA

It mainly uses photosensitive resin as a raw material, and utilizes the characteristic that liquid photosensitive resin will cure quickly under ultraviolet laser beam irradiation. The photosensitive resin is generally liquid, and it immediately initiates a polymerization reaction and completes curing when irradiated with a certain wavelength of ultraviolet light (250 nm to 400 nm). SLA focuses on the surface of the light-curing material by focusing ultraviolet light of a specific wavelength and intensity to solidify it sequentially from point to line and from line to surface, thereby completing the drawing of a layered cross-section.

3D Printing Shop

Rongna: IGES (.igs) /STEP (.stp) /Parasolid (.x_t) / .stl files.

Rongna: Sure. We never divulge customers' information to anyone else.

Rongna : 1 pcs , we provide prototype to mass production service

Rongna: Exress UPS/FedEx . shipping by sea

we help client Develop New Products, form Sample to mass Production.

Ningbo, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier