Video

1 / 2

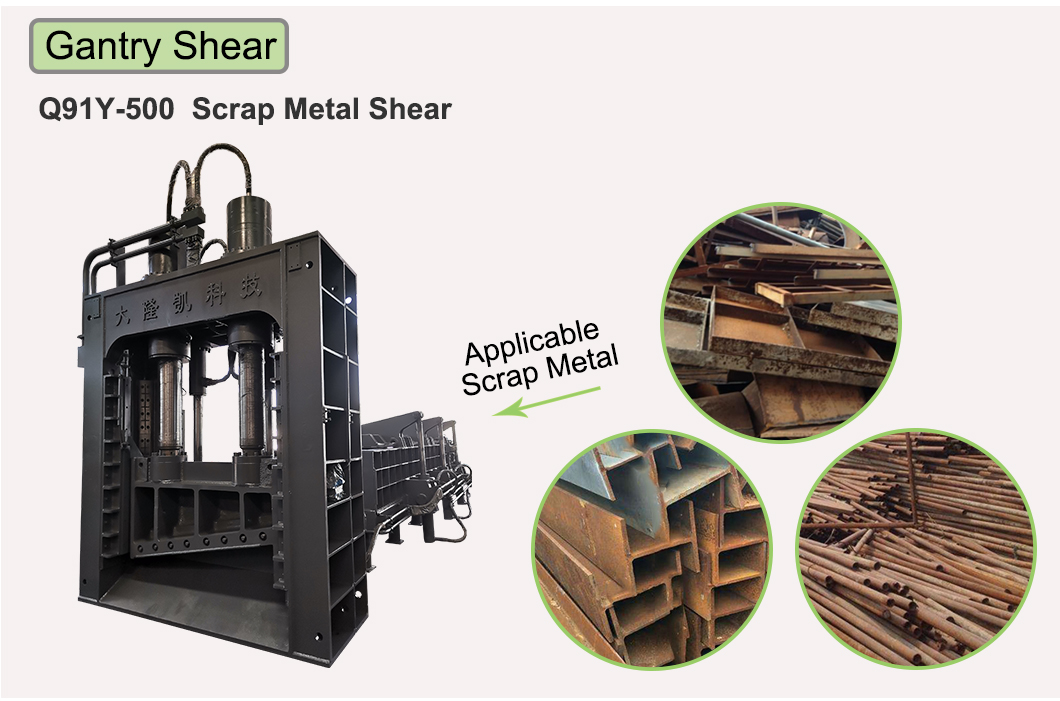

Q91Y-500 Hydraulic Scrap I-beam Shear Cutting Machine

Maximum cutting specification (mm):

- 1600 mm

| Model No. : | Q91Y-500 |

|---|---|

| Brand Name : | Dalongkai |

| place of origin : | China |

Wuxi, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Q91Y-500 Hydraulic Scrap I-beam Shear Cutting Machine

Product Description

Gantry shears are used for cutting various metal plates. They are ideal equipment for charge processing in rolling mills, non-ferrous metal plants, and smelters. Our shearing machine models are complete and can also be customized according to customer needs. All models are hydraulically driven, PLC automatic control operation. The size of the material box is large, and the range of the material size that can be processed is large.

Product advantages

1.The adoption of upper compression and two side compression of the whole shape and sectional feeding mode of scrap, the design of wide material box, so the applicability of scrap raw materials is good, and the compactness after shearing is high.

2.The opening area of the material box is large, which is suitable for machining materials, loose heavy waste, light and thin waste steel, automobile shell, large irregular light steel structure, steel pipe, steel plate, channel steel, I-beam, steel bar and other profiles cutting, easy to put into the material box, and fully enlarge the utilization rate of the equipment.

3.It adopts PLC automatic control touch screen type control panel automatic integrated control and multi angle whole process monitoring system, which is convenient for user control and whole process tracking of equipment use.

Technical parameters:

|

Model |

Max.Cutting Force(ton) |

Press Box Size(mm) |

Blade Length(mm) |

Cutting Frequency (times/min) |

Power (KW) |

|

Q91Y-400 |

400 |

6000*1300*500 |

1400 |

2-4 |

90 |

|

Q91Y-500 |

500 |

6000*1500*700 |

1600 |

2-4 |

110 |

|

Q91Y-630 |

630 |

8000*1700*1200 |

1800 |

2-4 |

150 |

|

Q91Y-800 |

800 |

8000*1900*1200 |

2000 |

2-4 |

225 |

|

Q91Y-1000 |

1000 |

8000*2000*1200 |

2500/2100 |

2-4 |

270 |

|

Q91Y-1250 |

1250 |

8000*2400*1200 |

2500 |

2-4 |

300 |

The parameters in the above table are for reference only.

Application

1. Compress and cut scrap metal, cut various bars and profiles;

2. A large amount of scrap metal is compressed together into a long piece;

3. Lightweight scrap steel is packed into blocks, and scrap cars are extruded into car briquettes.

Service

1. Professional and patient consulting service to help you find the suitable solution.

2. Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3. Free training in our plant during machine inspection.

4. For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

5. If you need to visit the factory, we will arrange for personnel to pick up the airport.

FAQ

1,Q:Can I add my logo on the machines?

A: Yes,OEM and ODM are available for us.

But you should send us the Trademark authorization letter.

2,Q:How can i get the after-service?

A: We will send you the spare parts by free if the problems caused by us.

If it is the men-made problems,we also send the spare parts,but you should pay.

3,Q:Do you have inspection procedures for machines?

A:100% self-inspection before packing

4,Q:Can I have a visit to your factory before the order?

A:Sure,welcome to visit our factory.

Here is our factory address:No.29, Panlongshan Road, Jiangyin City, Jiangsu Province, China.

5,Q: Can we order one set machine?

A:Yes, you can.

Video

Wuxi, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier