1 / 3

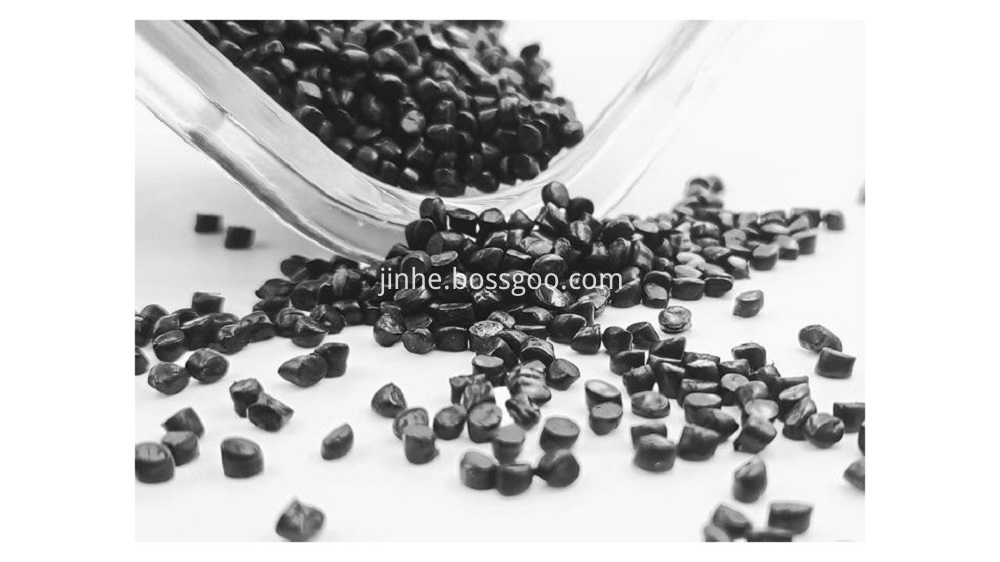

PVC Carbon Black Masterbatch For Pipe And Cable

$1250.00

≥5 Metric Ton

$1160.00

≥25 Metric Ton

Options:

- Application: injection molding,pelletizing,

- Application:pressing,film blowing, wire, pipe

- Dosage of black masterbatch:1-3%

- Appearance black masterbatch: 2.2*2.8 cyli

- Bulk specific gravity 25”C 950kg/m3

- Melting point: 130-350℃

- Dissolving finger: 30g/10min

- Moisture: 0.001%

- Packing: 25kg bag, 25.5mt/20'fcl

| Model No. : | Black Masterbatch |

|---|---|

| Brand Name : | Jinhe |

| place of origin : | China |

Zhengzhou, Henan, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

We are pioneers in providing a superlative spectrum of highly loaded Black masterbatches. By employing varied types and grades of carbon, we can offer diverse grades of black master batches. Plastiblends black master batches play a role in such key markets as agricultural, packaging, electronics, textiles and nonwovens, wire & cable, automotive and toys. Further, our R&D experts continuously inspect and update the existing range, as per the changing trends in the market. masterbatches are available with base carier PE, PP, PET, PS & EVA based on the end use application.We have rich experience in the production of black masterbatch, using the production equipment and testing instruments in the industry; the raw materials we choose are high-quality, high-dispersion carbon black and high-quality additives and carriers.

For different polymer materials, there are special carrier black masterbatches to choose from, we can fully

It is sufficient to meet the special requirements of customers for color tone, weather resistance, light resistance and food grade.

Carbon black content: 25%-50%

Product features: high carbon black content, good blackness, good dispersion, good temperature resistance, no effect on material properties.

Black masterbatch is a color masterbatch raw material produced by carbon black, carrier and auxiliary injection molding process.

CHARACTERISTICS OF BLACK MASTERBATCH

1. Black masterbatch heat resistance PVC, PE pigment temperature resistance 160-180 degrees Celsius, ABS, PS pigment temperature resistance 250-280 degrees Celsius 4-10 minutes, generally, the higher the use temperature, the shorter the heat resistance time. Phthalocyanine blue pigment can withstand temperature of 325 degrees Celsius and change color within 10 minutes.

2. Appearance of black masterbatch: 2.2*2.8

cylindrical black body.

2. Appearance of black masterbatch: 2.2*2.8

cylindrical black body.

3. Black masterbatch application range: It is suitable for most thermal resin injection molding, pelletizing, pressing, film blowing, wire, pipe and other processes.

4. Usage of black masterbatch: It can be produced by mixing with raw materials evenly.

5. Dosage of black masterbatch: The recommended dosage is 1%-3% (depending on product requirements)

6. Technical parameters: Bulk specific gravity 25”C 950kg/m3

7. Melting point: 130-350℃

8. Dissolving finger: 30g/10min

9. Moisture: 0.001%

10. Packing: 25kg/bag, polyethylene black self-sealing bag or paper-plastic composite bag

11. Advantages: High black, high brightness, easy to disperse, can achieve high-gloss mirror effect. Environmental protection, non-toxic, odorless, smoke-free, the product surface is smooth and shiny, solid color is stable, good toughness, no color spots and color streaks, etc., which not only reduces costs, saves additives, but also reduces plant site pollution.

12. Storage of black masterbatch: Store in a cool and dry place. Avoid exposure to sunlight and rain.

We could supply PVA Resin, PVC Resin, Titanium Dioxide, PVC Paste Resin, Iron Oxide, Chrome Green, Sodium Tripolyphosphate,

Sodium Hexametaphosphate, Carbon Black, Chlorinated Polyethylene, Modified Starch, Tung Oil, PVB Resin, PEG, Polyethylene Glycol etc.

Zhengzhou, Henan, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier