1 / 10

Professional Busbar Bending Machine

| Model No. : | EMAC-BB |

|---|---|

| Brand Name : | Euro-Asia |

| Certification : | CE |

Jinan, Shandong, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Product description

1. The bend unit (Y-axis) of the CNC busbar bending machine has the function of angle error compensation, its bending accuracy can meet the high performance norm.

2. Automatic Busbar Servo Bending Machine adopts unique large closed type bending structure.

3. Automatic CNC bending machine also has the convenience of the open type bending.

4. CNC busbar bending machine possesses the premium property of the closed type bending.

Advantages:

1.Closed Bending Structure --Using a precision linear guide to ensure fabricating accuracy.

2.3D Software Programming --Accurately calculating the punching position by 3D graphics.

3.Touch Screen -- Allowing the easy setting of die parameters and the operation of equipment.

4. High-Speed-- Operation System Guarantee high precision and fast efficiency.

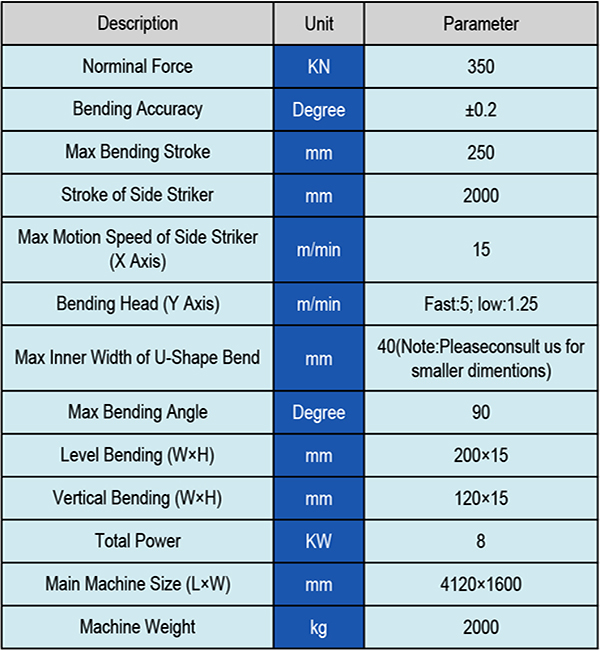

Main technical parameter:

Configuration:

Control Section

Serial No.

Name

Brand Name

1

Programmable Control

OMRON

2

Sensor

Telemacanique From Schneider

3

Control Button

OMRON

4

Touch Screen

OMRON

5

Computer

Lenovo

6

AC Contactors

ABB

7

Circuit Breaker

ABB

8

Servo Motors

YASKAWA(Japan)

9

Servo Drivers

YASKAWA(Japan)

10

Control software and Three-dimensional

computer-aided design

Gaoji Busbar Processing System(GJ3D)

Transmission System

Serial No.

Name

Brand Name

1

Precision Straight rail

Taiwan HIWIN

2

Precision Ball Screw

Taiwan HIWIN

3

Bearing

Japan NSK

Packing details

1) Applying Anti-Rust Oil

2) Covering with stretch film

3) Covering aluminum air bag

4) Vacuuming air bags

5) Boxing all the pallet

6) Loading to the container

Jinan, Shandong, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Send your inquiry to this supplier