1 / 2

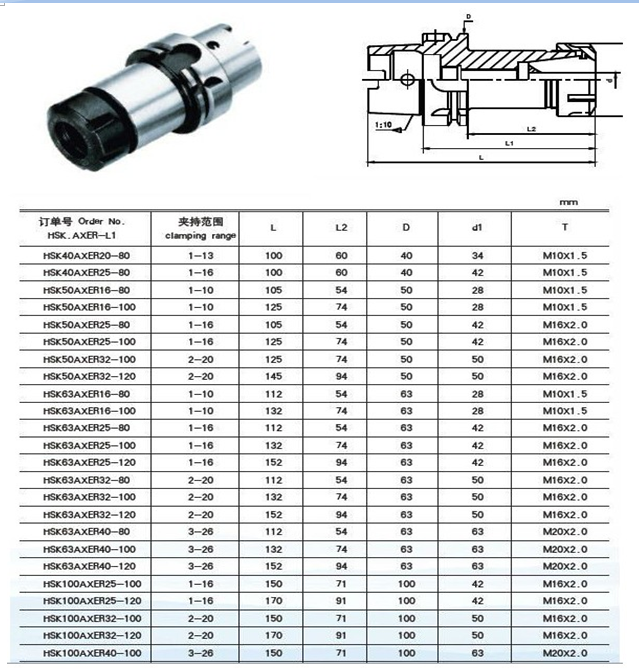

Precision HSK ER Collet CHUCK CNC tool holder

$1.00

≥1 Piece/Pieces

| Brand Name : | QFMH |

|---|---|

| place of origin : | China |

Jining, Shandong, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Product description

Precision HSK ER Collet CHUCK CNC tool holder, The unique double-layer positioning clamping mode is designed, the front and rear end stop of the thread is added, the rigidity of the handle is increased by 30%, the anti vibration knife has excellent dust-proof effect.It can be used for drilling, milling, twisting, tapping and other processing, with strong practicability and high cost performance.Please consult separately for customization of non-standard parts.

1. The double-sided contact of the flange end face and the short cone part of the knife handle can contact and clamp the mechanical spindle at the same time, so as to ensure high rigidity.

2. The end face position in the spindle direction and the vertebral body in the aperture direction ensure the high repetition accuracy of the tool handle setting, which is suitable for high-precision machining.

3. The taper shank section is light and convenient for automatic tool change.

4. During high-speed rotation, the cone of the central control shape follows the expansion of the main shaft, which can maintain high precision.

5. Support high pressure coolant applications.

6. After heat treatment of HSK taper handle, the hard cutting of the inner shoulder of the taper handle ensures: (1) pull down and lock the perfect concentricity of the shoulder (DIN standard 0.04); (2) Excellent runout accuracy; (3) Excellent spindle locking force; (4) Excellent radial rigidity.

7. After the heat treatment of HSK taper handle, the hard cutting of the contact surface between the taper handle and the main shaft ensures: (1) the safety of tool change; (2) Extend the life cycle of the claw.

8. All tool handles are precisely dynamically balanced to g2.5 25000rpm to ensure: (1) fast and stable operation of machine tool spindle; (2) Prolong the life cycle of spindle; (3) Improve tool life; (4) Higher surface processing quality.

Jining, Shandong, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier