Video

1 / 4

Precise Carbide CNC NC Spotting Drills for Centering

$1.00

/ Piece/Pieces

Diameter:

- 1-20mm

Comprehensive length:

- 75mm

Types:

- End Mill

Send Inquiry

| Brand Name : | OEM |

|---|---|

| Support customization : | Oem,Odm,Obm |

More

Supal(changzhou)Precision Tools Co.,Ltd

You might also like

Product description

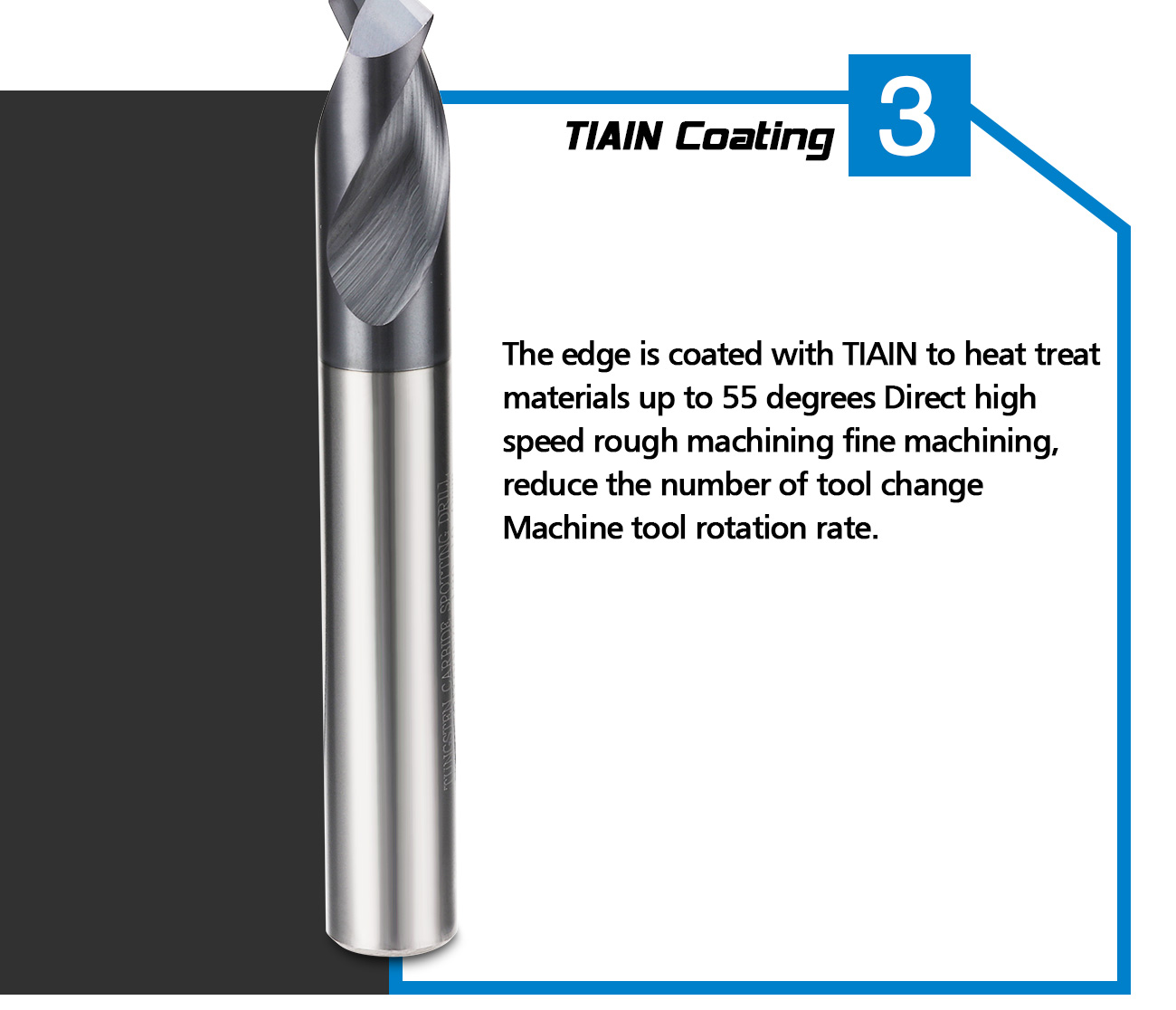

Tungsten carbode 120 degrees Solid Carbide Spotting Drill

Spot drilling prior to the full drill cycle can ensure accurate hole location by avoiding drill deflection. Spot Drilling is recommended when a drill might have a tendency to move off center and particularly recommend in deep-hole drilling. These drills are designed to be extremely rigid to precisely spot a hole for a twist drill. The primary purpose of a spot drill to make a "dimple" in the workpiece so that the twist drill does not deflect and "walk" off-center and the hole is drilled in the correct location .

About Spot Drills

A spot drill typically has a tight tolerance point geometry with a very short flute length.It is important to know that a spot drill has no land or body relief, and is NOT designed to drill past the depth of the point angle, which is just enough to drill an detent or "dimple" in the workpiece.

Spot drills are used to improve the accuracy of secondary drill operations but they can be used as a chamfering tool if the spot drill diameter is larger than the final hole size.

Ideally, the spot drill diameter should be about 70% of the size of your final drill diameter. The spot drill point angle should be greater than or less than the final drill’s point angle.

- Spot drilling is not recommended in hardened steels.

- Contacting the corners of the carbide drill before the center point in the opening of the hole could lead to corner chipping.

Using a spot drill with an angle less than the drill point angle WILL cause the drill flutes to be "blown off"

Never use a 90 ̊ Spot drill that will be followed by a 140 ̊ drill point!

Video

Send your inquiry to this supplier

Send Inquiry