1 / 2

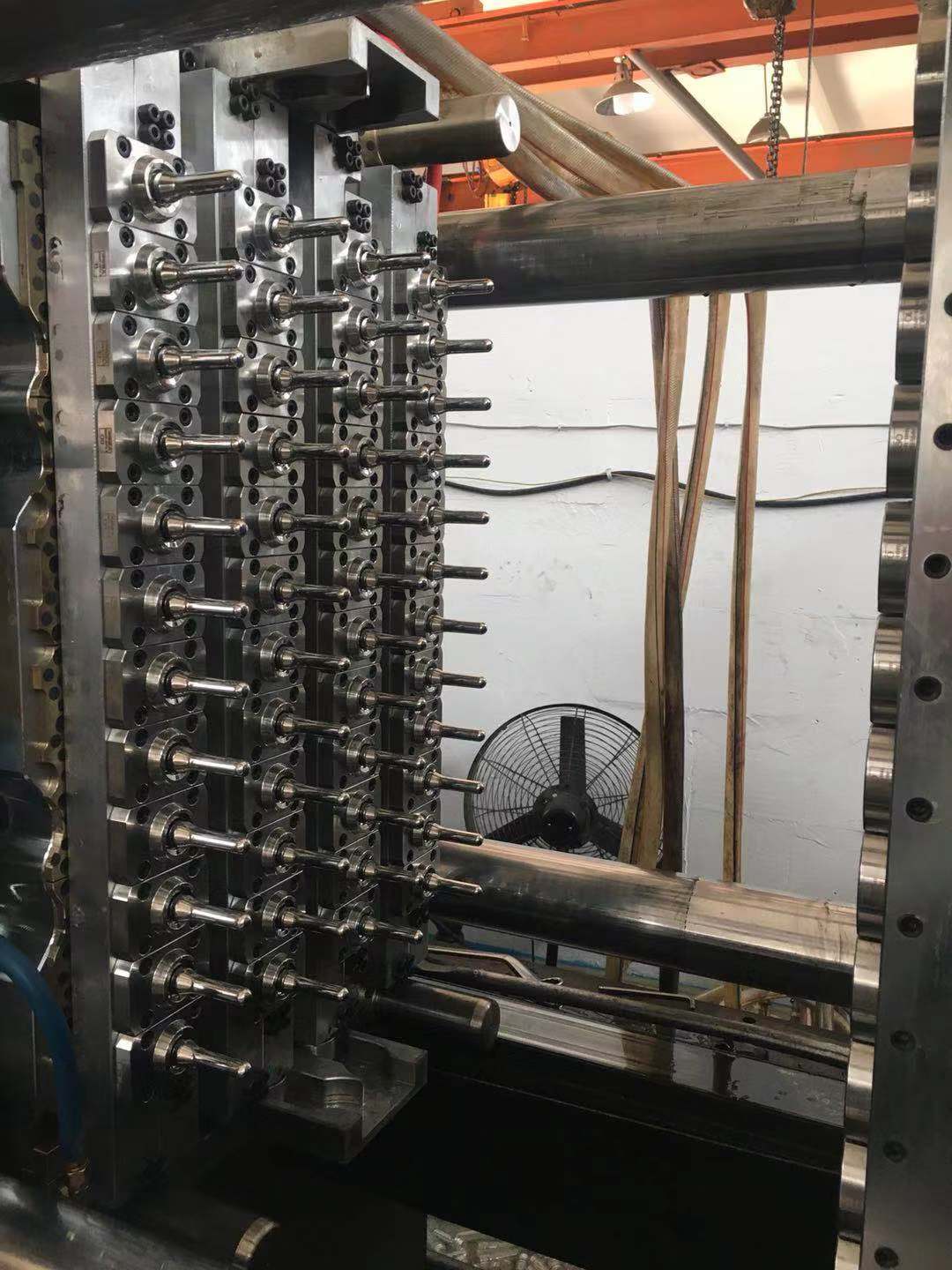

Plastic PET Preform Injection Mold

| Model No. : | 32 Cavity |

|---|---|

| Brand Name : | Winiber |

| Application : | Commodity |

Wenzhou, Zhejiang, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Product description

Product Description

Plastic PET Preform Injection Mold is an injection mould, which is suitable for producing PET preforms. There are many prforms with different neck and weight for different bottles, such as the carbonated bottle, mineral water bottle, , pesticide bottle, oil bottle, cosmetics bottle, wide-mouth bottle and hot fill bottle etc.

Plastic PET Injection Mold Feature

1. High accuracy and easy maintanceWith high precision imported machine tool, all the spare parts can be interchanged to save the maintaince time and guarantee the preform weight difference.

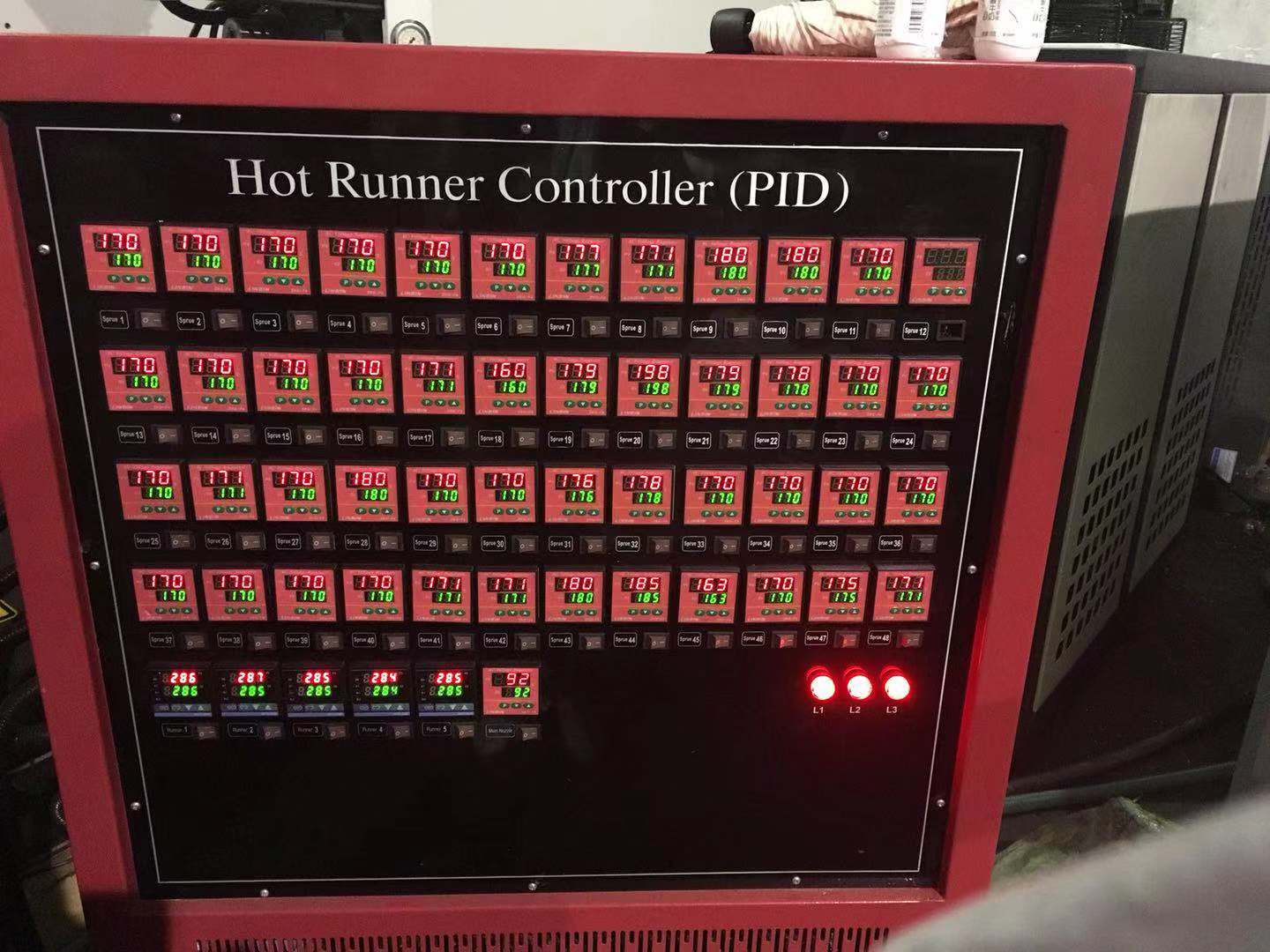

Independent hot runner system, even one cavity is broken, others still work.

The temperature controller is controlled by PID. It can be changed on working condition.

Core, cavity and neck screw is controlled by the double cone positioning to ensure does not appear flash, different size, irregualr and other defects.

2. High effiency and Low cost

- using Germany heating ring HOTSET only 268W, the traditional one 320W, save 20% electricity cost. Lower AA level and be more environmental.

- Hot runner production, save labor cost. One worker can work for 3 or 4 sets of injection machine

- Large diameter pipe make the mould cool fast and well. Shorten cycle time.

- Adopt double ejection device, pulley sliding and ejector sleeve to make sure the preform can be ejected smoothly without the robot hand.

3. Durable

- Use P20 pre-hardened steel as the pet preform mould plate to make complete structure stable, not easy transformation.

- All the mould plate rust-proof handling, decrease the second pollution during the production.

- Core, cavity and screw all use S136 stainless steel. After the vacuum treatment, hardness 48-50HRC.

- Guarantee: 5 million shots.

Mould Specification

| Cavity Number | 22g Preform Length:94mm | 32g Preform Length:120mm | 42g Preform Length:130mm | |||

| Dimension(mm) | Weight(kg) | Dimension(mm) | Weight(kg) | Dimension(mm) | Weight(kg) | |

| 4(1*4) | 500*290*430 | 550 | 500*290*445 | 600 | 500*290*455 | 680 |

| 6(2*3) | 430*370*400 | 760 | 430*370*415 | 850 | 430*370*425 | 900 |

| 8(2*4) | 490*370*435 | 810 | 490*370*450 | 900 | 490*370*460 | 970 |

| 12(2*6) | 630*370*435 | 1020 | 630*370*450 | 1100 | 630*370*460 | 1180 |

| 12(2*8) | 750*370*480 | 1240 | 750*370*495 | 1350 | 750*370*505 | 1450 |

| 24(3*8) | 830*440*500 | 1880 | 830*440*515 | 1950 | 830*440*525 | 2060 |

| 32(4*8) | 830*580*515 | 2360 | 830*580*530 | 2250 | 830*580*545 | 2600 |

| 48(4*12) | 1065*580*525 | 2930 | 1065*580*540 | 3050 | 1065*580*555 | 3150 |

| 72(6*12) | 1140*830*560 | 4320 | 1140*830*575 | 4450 | 1140*830*580 | 4600 |

Detailed Photos of PET Preform Injection Mould

About us

We have more than 20 years knowledge and experience on PET Water/juice/carbonated drinks production line. Our exporting product includes: Injection molding machine, PET preform mould, plastic bottle blowing machine, Water treatment system, Filling machine and Packaging machine etc.

Q: What is the warranty if we buy your machines?

A: We offer the high quality machines with 1 year guarantee start from the machine reach to your factory. Also you share the lifelong technical support.

Q: How about the spare parts?

A: We will send one year enough spare parts together with machines for your stock. During the warranty time, if some spare parts broke without human problem, we will send free for you.

Q: How to install my machines when it arrives? What is the cost?

A: We will send our engineer to your factory to install the machines and train your engineers how to operate and maintain the machines. Customer pay for visa, round-trip tickets, room and accommodation, USD80/day/ person(engineer salary).

Q: How long time for installation?

A: According to the machine you order, usually we will send one or two engineer, it takes about 7to 20days.

Q: When can I get my machine after I paid?

A: Usually the production time is around 25-60 days. The exactly will be decided by which machine u order.

Wenzhou, Zhejiang, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier