1 / 4

Plastic casing prototyping vacuum casting 3d printing

$30.00

~ $200.00

/ Piece/Pieces

Send Inquiry

| Model No. : | haoyi-1 |

|---|---|

| Brand Name : | Haoyi |

| Tolerance : | +/-0.01mm |

More

YuYao Haoyi Model Factory

You might also like

Product description

Overview:Vacuum building is a physical mode method, it combines vacuum technology and sand casting, sand by plastic film will die cavity surface and sealed on the back, with the help of vacuum pump suction to produce negative pressure, caused by sand mould sand mold clamp with internal and external pressure forming, the core was laid, moulding, casting, after waiting for casting solidification, remove or stop the smoke gas, negative pressure mould sand casting is melted away.According to the present the main areas of application can be divided into the vacuum sealing building (V) and firm type vacuum casting method (FV).Its advantage is:

Cavity (1) appropriate vacuum degree, high compactness, casting quality is also high.

(2) vacuum casting mold flow analysis of the simulation with computers, can predict casting defects, to the design of the building plan, can greatly save time, improve production efficiency.Vacuum building is a physical mode method, it combines vacuum technology and sand casting, sand by plastic film will die cavity surface and sealed on the back, with the help of vacuum pump suction to produce negative pressure, caused by sand mould sand mold clamp with internal and external pressure forming, the core was laid, moulding, casting, after waiting for casting solidification, remove or stop the smoke gas, negative pressure mould sand casting is melted away.According to the present the main areas of application can be divided into the vacuum sealing building (V) and firm type vacuum casting method (FV).Its advantage is:

Cavity (1) appropriate vacuum degree, high compactness, casting quality is also high.

(2) vacuum casting mold flow analysis of the simulation with computers, can predict casting defects, to the design of the building plan, can greatly save time, improve production efficiency.

Cavity (1) appropriate vacuum degree, high compactness, casting quality is also high.

(2) vacuum casting mold flow analysis of the simulation with computers, can predict casting defects, to the design of the building plan, can greatly save time, improve production efficiency.Vacuum building is a physical mode method, it combines vacuum technology and sand casting, sand by plastic film will die cavity surface and sealed on the back, with the help of vacuum pump suction to produce negative pressure, caused by sand mould sand mold clamp with internal and external pressure forming, the core was laid, moulding, casting, after waiting for casting solidification, remove or stop the smoke gas, negative pressure mould sand casting is melted away.According to the present the main areas of application can be divided into the vacuum sealing building (V) and firm type vacuum casting method (FV).Its advantage is:

Cavity (1) appropriate vacuum degree, high compactness, casting quality is also high.

(2) vacuum casting mold flow analysis of the simulation with computers, can predict casting defects, to the design of the building plan, can greatly save time, improve production efficiency.

|

Item

|

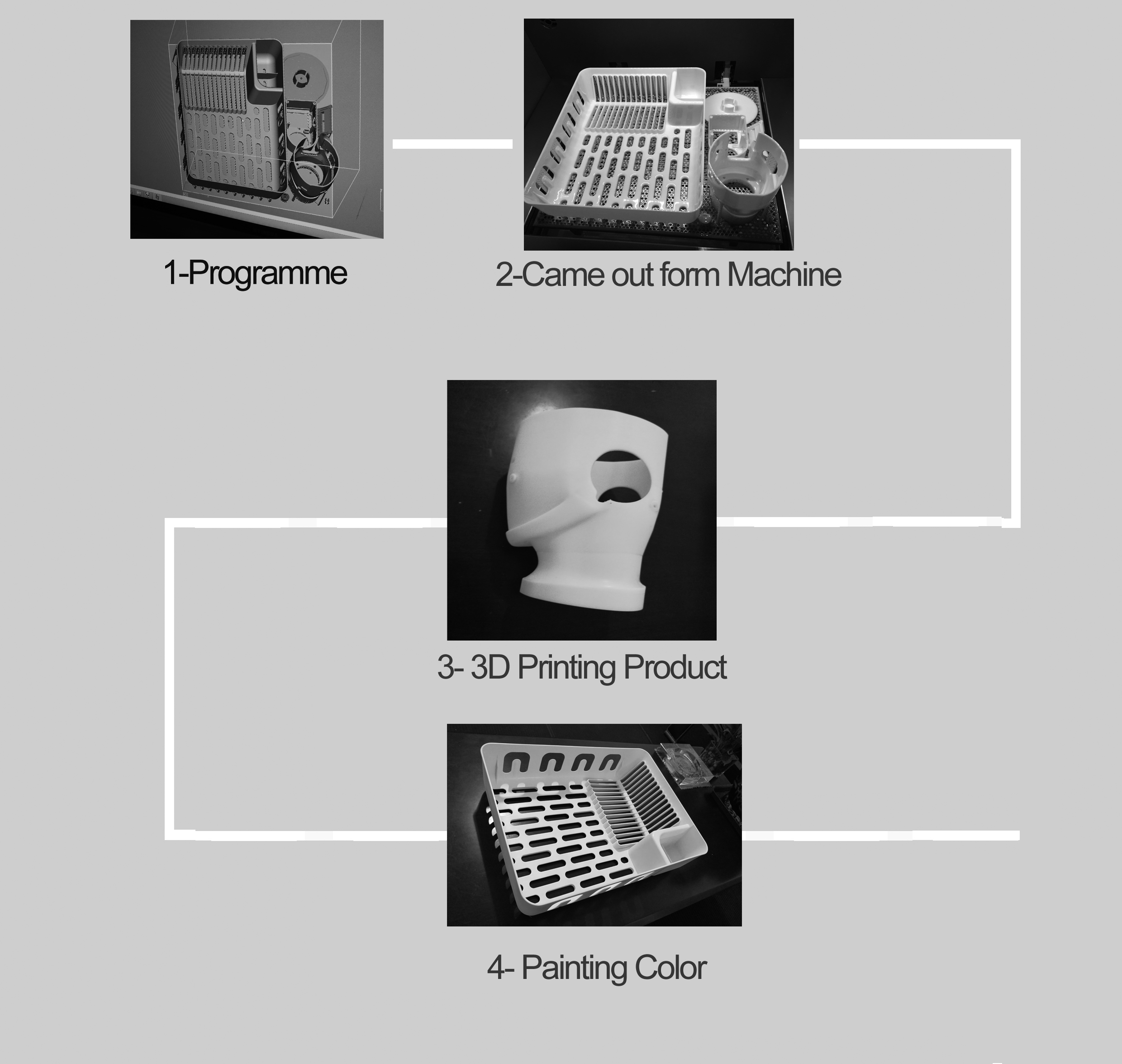

3D Printing

|

|

Material available

|

Plastic,Metal , Titanium, etc.

|

|

Surface treatment

|

Painitng, Electroplating, etc.

|

|

Processing

|

SLA / SLS

|

|

Tolerance

|

+/-0.01mm

|

|

File Format

|

Step/ igs /stl/Solid Works / UG

|

|

Production capacity

|

According to Customer`s Drawings

|

|

Experience

|

12 years of machining products

|

|

Packaging

|

Standard Export Carton with pallet or as per customes'requirement

|

|

Lead time

|

2-30 Days,Accoring to Quantity(ASAP)

|

|

Term of Payment

|

T/T / L/C / /Paypal

|

3D Printing PROCESS

HAOYI MODEL FACTORY

CERTIFICATIONS

PACKING&DELIVERY

Packing Details : Standard Export Carton/wooden Box or as per customes'requirement

Delivery Details : 2-30 days after place order

FAQ

Q: What is your MOQ?

A: 1 pcs

Q: How do I get a quote?

A: Send us inquiry, we would contact you ASAP

Q:Which payments do you accept?

A: T/T and Paypal

Q: What is your terms of payment ?

A: 50% Deposit,Pay balance before shipping

Supplier's popular products

Send your inquiry to this supplier

Send Inquiry