Video

1 / 3

Operator Friendly Rubber Roller Grooving Machine

| Model No. : | PSM-8040-CNC |

|---|---|

| Brand Name : | Power |

| Warranty : | 1 Year |

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

PSM-8040-CNC Rubber Roller Grinding / Slotting / Groover / Grooving / Grinder Machines

Base on the basic PSM series general grinding machine, PSM-CNC series is developed by changed the driven type and control system. CNC system is specialized digital-controlled software for roll processing.

The past roller processing method by metallic manufacturing equipment can be replaced by our PSM series rubber roller grinding machine which is specially designed and manufactured .

1. It has our own developed user-friendly CNC operating system.

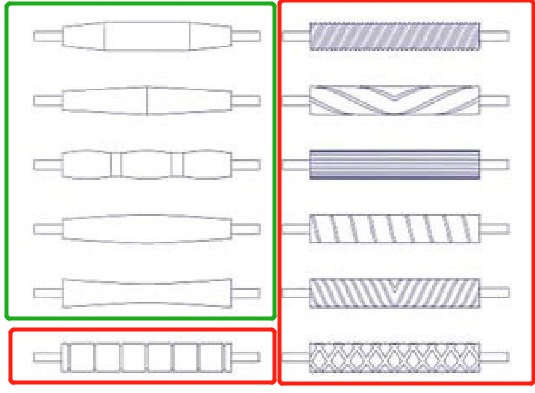

2. The latest system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc.

3. Remote problem solving function availabe.

4. Having all the functions of our PSM series general grinding machine.

The feature of PSM series general grinding machine

1. Standard equipment of PSM series includes:

a. a full flood recirculating coolant system

b. motorized tailstock

c. variable speed traverse and spindle drives

d. front and rear independently operated carriage tables

e. a direct drive grinding head mounted on the rear

2. Specially designed to replace the tradtional roller grinding process method.

3. Two medium carriage tables assembled to ensure accurate performance and operating stability.

4. The max. linear speed of grinding head is over 90m/s. Production efficiency is highly increased and the geometric size is guaranteed.

5. Advanced measuring device assembled timely checks the processing datas and provides effective help to control the grinding size.

6. Capable of realizing expansion of processing of special-shaped rubber rollers.

|

MODEL

|

SPECIFICATION

|

MAX. DIAMETER

|

MAX. LENGTH

|

CUBAGE

|

POWER

|

|

LIGHT SCALE

|

PSM-4020-CNC

|

16"

400mm

|

80"

2000mm

|

158"*63"*55"

4m*1.6m*1.4m

|

17KW

|

|

STANDARD

|

PSM-8040-CNC

|

32"

800mm

|

158"

4000mm

|

256"*71"*63"

6.5m*1.8m*1.6m

|

22KW

|

|

HEAVY DUTY

|

PSM-1260-CNC

|

47"

1200mm

|

236"

6000mm

|

315"*79"*71"

8.0m*2.0m*1.8m

|

26KW

|

|

LARGE SCALE

|

PSM-1680-CNC

|

63"

1600mm

|

315"

8000mm

|

433"*95"*71"

11m*2.4m*1.8m

|

32KW

|

Due to the all-round of the system function, it can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.

Packaging & Shipping

- Packing details:

1. Outside package: Standard export wooden cases

2. Inner package: Stretch film

- Delivery time:

![E)2NNH)N65UT`JP`@ST`L]P E)2NNH)N65UT`JP`@ST`L]P](http://bsg-i.nbxc.com/product/2d/d1/19/3efbc91c3b8ac25821255756af.png@watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=22&p=5&t=80&text=amluYW5wb3dlci5ib3NzZ29vLmNvbQ%3D%3D)

![39]4`2O1G`KUL7FR8SI}G[D 39]4`2O1G`KUL7FR8SI}G[D](http://bsg-i.nbxc.com/product/90/8e/cc/abfdfcaceb560d7dc2707165c1.png@watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=22&p=5&t=80&text=amluYW5wb3dlci5ib3NzZ29vLmNvbQ%3D%3D)

Products Certification

Factory

Customers:

![YTOQ5@]K955VJ2T`S[)~I%9 YTOQ5@]K955VJ2T`S[)~I%9](http://bsg-i.nbxc.com/product/28/29/3f/7497750b8b45426d66be53b8ca.png@watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=22&p=5&t=80&text=amluYW5wb3dlci5ib3NzZ29vLmNvbQ%3D%3D)

![3JY(T]L5RRSA[%FG4N1L_LB 3JY(T]L5RRSA[%FG4N1L_LB](http://bsg-i.nbxc.com/product/c5/05/45/f67f798d293c3667d08d949bf6.png@watermark=2&color=I0ZGRkZGRg%3D%3D&type=ZHJvaWRzYW5zZmFsbGJhY2s%3D&size=22&p=5&t=80&text=amluYW5wb3dlci5ib3NzZ29vLmNvbQ%3D%3D)

Contract Us

Please feel free to contact us for any question, we will reply within 24h.

Thanks for visiting!

Video

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier