Video

1 / 4

NM 400 Wear Steel Sheet

Options:

- 0.35*1000mm

- 1.5*3800mm

| Model No. : | NM 400 |

|---|---|

| Brand Name : | CHANGYI |

| standard : | Aisi |

Liaocheng, Shandong, China

- Agent

- Distributor/Wholesaler

- Service

- Trade Company

- Gold Supplier

- Platform Certification

Product description

High Tensile Nm 400 Wear Steel Sheet refers to special plate products designed for use in large-area wear conditions. The commonly used High Tensile Nm 400 Wear Steel Sheet is a plate product made of a certain thickness of alloy wear-resistant layer with high hardness and excellent wear resistance on the surface of ordinary low-carbon steel or low-alloy steel with good toughness and plasticity by surfacing method. In addition, there are cast wear-resistant steel plates and alloy quenched wear-resistant steel sheets.

Corten A/B,A588 Gr A/B/C,A242 Type 1,A606 Type 4 SPA-H,Q345GNHL ,Q235NH,Q355NH ,09CuPS235JOW,S235J2W,S355JOWP,S355J2WP,S355JOW

NM360, NM400, NM450, NM500,NR360, NR400,B-HARD360, B-HARD400, B-HARD450

KN-55, KN-60, KN-63,AR400, AR450, AR500, AR600

Widely used in marine components, building steel structure components, substation auxiliary facilities,

light industry, etc.

1.Short delivery time

2.Quality assurance

3.Competitive price,

4.Free Sample

Wear/Abrasion Resistant Steel --- Chinese Standard

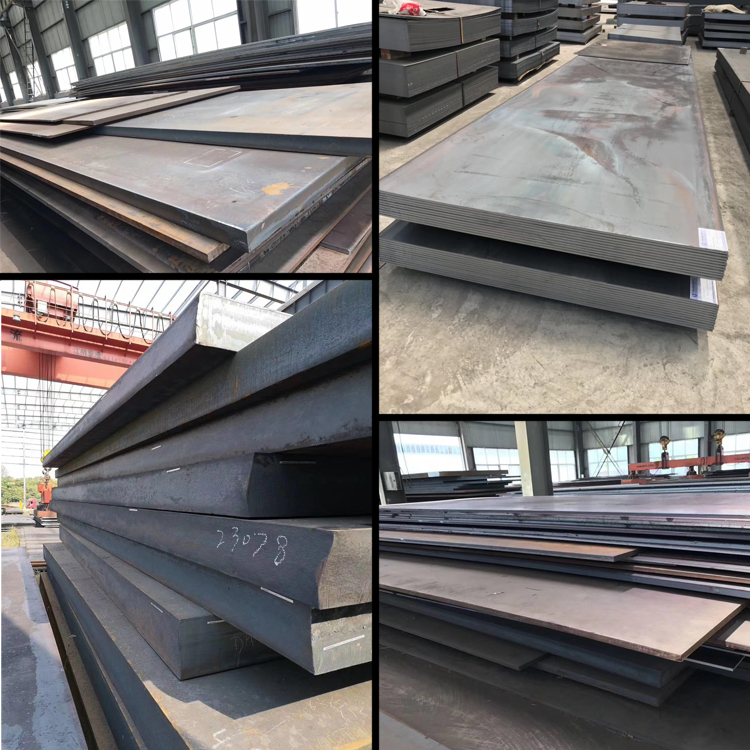

Product Show:

The steel plate is a flat steel that is cast with molten steel and pressed after cooling.

Production Process:

1. Hot Rolled Steel Plate

Appliction:

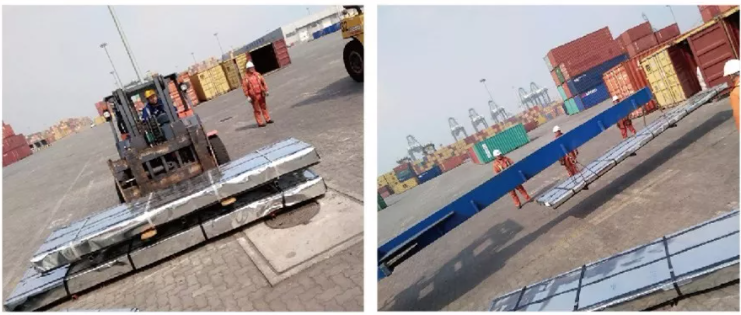

Packing and Shipping:

FAQ:

The High Tensile Nm 500 Wear Steel Sheet is composed of a low-carbon steel plate and an alloy wear-resistant layer. The alloy wear-resistant layer is generally 1/3~1/2 of the total thickness. When working, the matrix provides comprehensive properties such as strength, toughness and plasticity against external forces, and the alloy wear-resistant layer provides wear-resistant properties that meet the requirements of specified working conditions.

There is a metallurgical bond between the wear-resistant steel plate alloy wear-resistant layer and the substrate. Through special equipment and automatic welding process, the high-hardness self-protected alloy welding wire is uniformly welded on the substrate, and the number of composite layers is one to two or even multiple layers. During the composite process, due to the different shrinkage ratio of the alloy, uniform transverse cracks appear. It is a distinctive feature of wear-resistant steel plate.

The Nm 400 is mainly composed of chromium alloy, and other alloy components such as manganese, molybdenum, niobium, and nickel are also added. The carbides in the metallographic structure are distributed in fibers, and the fiber direction is perpendicular to the surface. The microhardness of carbide can reach HV1700-2000 or more, and the surface hardness can reach HRC58-62. Alloy carbide has strong stability at high temperature, maintains high hardness, and also has good oxidation resistance, and can be used normally within 500 ℃.

Description:

Product Name

NM 400 Wear Steel Sheet

Standard

ASTM DIN JIS GB

Material

Technology

Hot Rolled ,Cold Rolled

Tolerance

Control with in the standard, OD:+/-1%, WT:+/-5%

Application

Payment Terms

1.FOB 30%T/T,70% Before shipment

2.CIF 30% Pre-payment , Balance must be paid before shipment

3.Irrevocable 100% L/C at sight

Third Party Inspection

SGS ,BV, MTC

Advantages

Delivery Time

Within 25 days after receipt of advance payment

Wear/Abrasion Resistant Steel Equivalent Standards

Steel Grade

SSAB

JFE

DILLIDUR

ThyssenkKrupp

Ruukki

NM360

-

EH360

-

-

-

NM400

HARDOX400

EH400

400V

XAR400

Raex400

NM450

HARDOX450

-

450V

XAR450

Raex450

NM500

HARDOX500

EH500

500V

XAR500

Raex500

Chemical Composition (%) of NM Wear Resistant Steel

Steel Grade

C

Si

Mn

P

S

Cr

Mo

B

N

H

Ceq

NM360/NM400

≤0.20

≤0.40

≤1.50

≤0.012

≤0.005

≤0.35

≤0.30

≤0.002

≤0.005

≤0.00025

≤0.53

NM450

≤0.22

≤0.60

≤1.50

≤0.012

≤0.005

≤0.80

≤0.30

≤0.002

≤0.005

≤0.00025

≤0.62

NM500

≤0.30

≤0.60

≤1.00

≤0.012

≤0.002

≤1.00

≤0.30

≤0.002

≤0.005

≤0.0002

≤0.65

NM550

≤0.35

≤0.40

≤1.20

≤0.010

≤0.002

≤1.00

≤0.30

≤0.002

≤0.0045

≤0.0002

≤0.72

Wear/Abrasion Resistant Steel --- USA Standard

Mechanical Properties of NM Wear Resistant Steel

Steel Grade

Yield Strength /MPa

Tensile Strength /MPa

Elongation A50 /%

Hardess (Brinell) HBW10/3000

Impact/J (-20℃)

NM360

≥900

≥1050

≥12

320-390

≥21

NM400

≥950

≥1200

≥12

380-430

≥21

NM450

≥1050

≥1250

≥7

420-480

≥21

NM500

≥1100

≥1350

≥6

≥470

≥17

NM550

-

-

-

≥530

-

Abrasion Resistant Steel Plate Availabillity

Grade

Thickness

Width

Length

AR200 / AR 235

3/16" – 3/4"

48" – 120"

96" – 480"

AR400F

3/16" – 4"

48" – 120"

96" – 480"

AR450F

3/16" – 2 "

48" – 96 "

96" – 480"

AR500

3/16" – 2 "

48" – 96 "

96" – 480"

AR600

3/16" – 3/4"

48" – 96 "

96" – 480"

Chemical Composition of Abrasion Resistant Steel Plate

Grade

C

Si

Mn

P

S

Cr

Ni

Mo

B

AR500

0.3

0.7

1.7

0.025

0.015

1

0.7

0.5

0.005

AR450

0.26

0.7

1.7

0.025

0.015

1

0.7

0.5

0.005

AR400

0.25

0.7

1.7

0.025

0.015

1.5

0.7

0.5

0.005

AR300

0.18

0.7

1.7

0.025

0.015

1.5

0.4

0.5

0.005

Mechanical Properties of Abrasion Resistant Steel Plate

Grade

Yield Strength MPa

Tensile Strength MPa

Elongation A

Impact Strength Charpy V 20J

Hardness Range

AR500

1250

1450

8

-30C

450-540

AR450

1200

1450

8

-40C

420-500

AR400

1000

1250

10

-40C

360-480

AR300

900

1000

11

-40C

-

The steel sheet is flat, rectangular and can be directly rolled or cut from wide steel strips.

The steel plates is divided according to the thickness, the thin steel plate is less than 4 mm (the thinnest is 0.2 mm), the medium-thick steel plate is 4-60 mm, and the extra-thick steel plate is 60-115 mm.

Steel sheets are divided into hot rolling plate and cold rolling plate according to rolling.

Hot rolling processing methods include hot rolling, forging, extrusion and other methods.

2. Cold Rolled Steel Plate

Cold rolling processing methods include cold rolling, cold drawing and cold drawing, cold bending, cold extrusion and other methods.

The cold rolling method is to continue processing the hot rolled steel below the recrystallization temperature to make it cold rolled steel. Using cold rolling processing method can improve the mechanical properties of steel, and obtain products with high dimensional accuracy and certain smoothness.

Q: Are you a manufacturer?

A: Yes , we are a Carbon Steel Sheet manufacturer, We have own factory, which is located in Shandong,China. We have a leading power in producing and exporting carbon steel plate,cold rolled steel sheet, etc. We promise that we are what you are looking for.

Q:Can we visit your factory ?

A:Warmly welcome once we have your schedule we will pick you up .

Q: Do you have quality control?

A: Yes, we can accept BV, SGS third inspection .

Q: Can you arrange the shipment?

A: Sure, we have permanent freight forwarder who can gain the best price from most ship company and offer professional service.

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q:How can we get the offer?

A:Please offer the specification of the product,such as material,size,shape,etc.So we can give the best offer.

Q:Can we get the some samples?Any charges?

A:Yes,you can get available samples in our stock.Free for real samples,but customers need to pay the freight cost.

Q: How do you make our business long-term and good relationship ?

A: 1.We keep good quality and competitive price to ensure our customers' benefit.

2.We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Video

Liaocheng, Shandong, China

- Agent

- Distributor/Wholesaler

- Service

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier