1 / 3

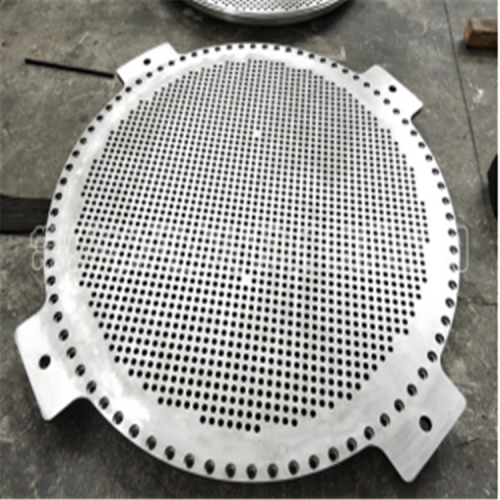

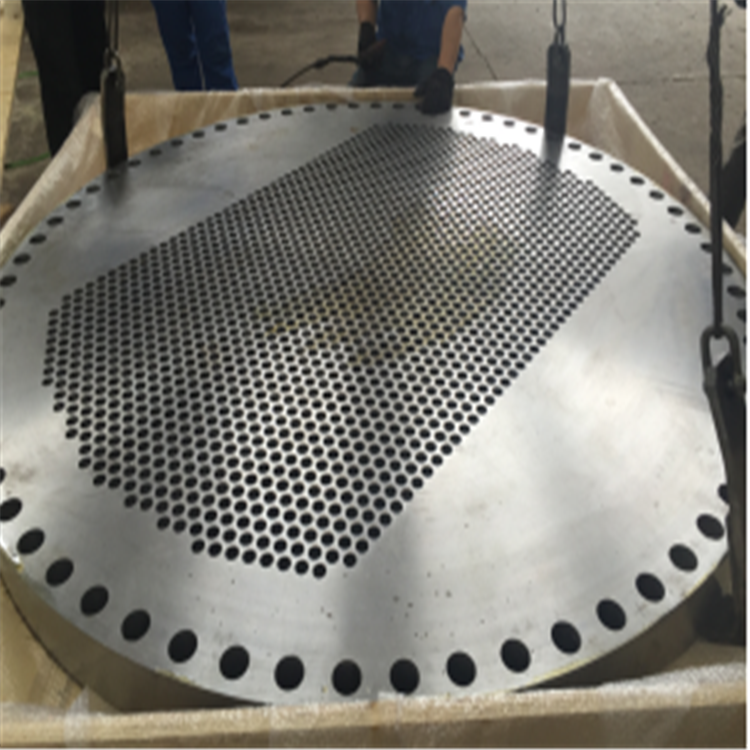

Multi-Pass Fixed Tube Sheet

$40.00

≥50 Kilogram

| Brand Name : | TORICH |

|---|---|

| Application : | Heat Exchanger |

Ningbo, Zhejiang, China

- Distributor/Wholesaler

- Manufacturer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Product description

Multi-Pass Fixed Tube Sheet

Shell and tube heat exchangers consist of a cylindrical shell with a bundle of tubes inside it. They work by circulating a hot liquid inside the shell around the tubes, which contain a cooler liquid.

In a fixed tube sheet heat exchanger, the tubes are permanently positioned inside the shell and thus are not removable. In a multi-pass heat exchanger, the liquid passes through the tube bundle two or more times.

DAC Worldwide’s Multi-Pass Fixed Tube Sheet Heat Exchanger Training Model (286) is a highly-detailed scale model that teaches learners about the operation and maintenance of industrial multi-pass fixed tube sheet heat exchangers.

An accurate, to-scale replica of a typical industrial heat exchanger, the model features a clear acrylic shell and can be completely disassembled. It reflects design standards established by both the Tubular Exchanger Manufacturers Association (TEMA) and the American Society of Mechanical Engineers (ASME).

Features & Specifications

- Exact "to-scale" construction throughout (5" shell diameter).

- Clear acrylic shell, flanges, and nozzles.

- Contrasting opaque baffles and partitions.

- Detailed tube bundle.

- Representative, color-coded tubing for visibility and to show flow path.

- Opaque representative gaskets.

- Stainless steel hardware.

- Durable PVC baseplate with provision for tabletop mounting and mounting on related workstation and display rack products.

- Metal Trades Training Manual with a section on heat exchanger design, maintenance, and nomenclature (IPT).

- Packaging for shipment via motor freight.

Product Pictures:

Company Introduction:

Packing and Delivery:

Quality Control:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate longitudinal and transversal defects.

ASTM B265 Hot Rolled Titanium Plates TA1 Plate Heat Exchanger Sheet

Ningbo, Zhejiang, China

- Distributor/Wholesaler

- Manufacturer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier