1 / 1

Mining Processing Ore Powder Rotary Drying Machine

Get Latest Price

Send Inquiry

| Brand Name : | Huahong |

|---|

Zhengzhou Huahong Machinery Equipment Co., Ltd.

You might also like

Product description

Specifications Mining powder dryer :

1. Use for the coal ,sawdust ,sand etc

2. Easy to perate.

3. Fuel:oil,gas,coal ,wood

4 CE,

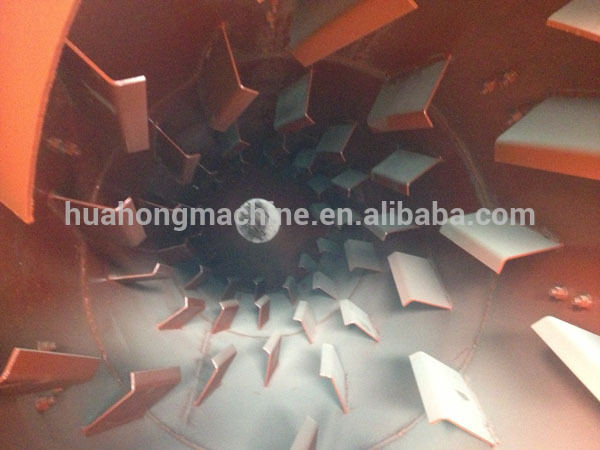

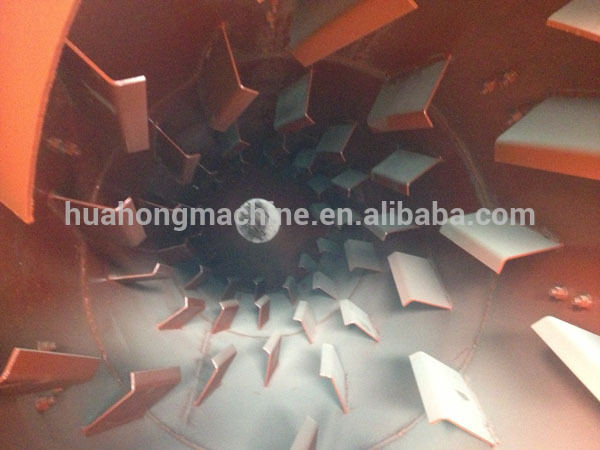

Specifications: Rotary Dryer is used in building material, metallurgy, chemical industry, cement to dry the slag, limestone, coal powder, clay Product Discription of Rotary Dryer: Rotary Dryer is a kind of machine with a rotating cylinder which is a little bit incline. It is widely used in building material, metallurgy, chemical industry, cement to dry the slag, limestone, coal powder, clay, etc. It is simply structure, polished manufacture, high capacity, low consumption, convenient transportation and so on. Rotary drum drier mainly consists of rotary body, raw material feeding plate, driving and supporting device, etc.

Operation Principle of Rotary Drying Machine: The raw material plate which is arranged reasonably with changeable angles in order, throws moisture materials into the rotary cylinder. Then water will be separated from the materials by hot air-flow and changed into vapour to be discharged into the atmosphere. Then the materials would be dried. Rotary dryer is used to dry slag, clay, limestone; It is mainly used for cement, chemical, metallurgical, building materials industries. Its advantages are as follows: high dry capacity, smooth rotation, and low energy consumption, easy operation, high output and so on.

Advantages of rotary dryer: 1.Three drum dryer use telescope-feed structure, dry the material quickly. 2.Simple design, self-insulation, improve the heat efficiency to exceed 80%. 3.Structure delicate, stable operation. 4.good drying performance, coal consumption <8kg when drying 1 ton material. 5.The fuel can be coal, oil, natural gas etc, dry mass, granule and powder material. 6.Reduce land area for 50% compared to single drum rotary dryer, so construction investment is saved 50%power consumption saved 60%. 7.Finished product moisture can be adjusted depends on requirement of client. 8.Lower outlet tempreture, loonger dust removal using life. 9.Drive by tug not gear. 10.Finished product tempreture lower than 60°C, packing can be done continuously. Main technical parameters of rotary drying machine:

Note: This specification is just reference, any changes are subject to the products. Pictures of rotary drying machine:

Details of rotary drying machine:

Our factory: Zhengzhou Huahong Machinery Equipment Co., Ltd. is a professional mining machine manufacturer with decades of years' experience. Our main product are grinding mills, Crushers,Dryer,Ball Mill, Sand making&washing machines, vibrating screens, etc Why Choose Us: We are the manufactory, we can provide you ex-factory price; Strictly quality control system; Professional technical online service; Any mail or message will be replied within 8 hours; Completive manufactory price; We have many large ore dressing line; We will provide equipment operation training for our client; We have a professional after-sale service team to promptly solve your problems.

Our service: Mining machines design and manufacture.

Technical engineer is available to the construction site for installation instruction and trial operation.

Customization is available.

1. Use for the coal ,sawdust ,sand etc

2. Easy to perate.

3. Fuel:oil,gas,coal ,wood

4 CE,

Specifications: Rotary Dryer is used in building material, metallurgy, chemical industry, cement to dry the slag, limestone, coal powder, clay Product Discription of Rotary Dryer: Rotary Dryer is a kind of machine with a rotating cylinder which is a little bit incline. It is widely used in building material, metallurgy, chemical industry, cement to dry the slag, limestone, coal powder, clay, etc. It is simply structure, polished manufacture, high capacity, low consumption, convenient transportation and so on. Rotary drum drier mainly consists of rotary body, raw material feeding plate, driving and supporting device, etc.

Operation Principle of Rotary Drying Machine: The raw material plate which is arranged reasonably with changeable angles in order, throws moisture materials into the rotary cylinder. Then water will be separated from the materials by hot air-flow and changed into vapour to be discharged into the atmosphere. Then the materials would be dried. Rotary dryer is used to dry slag, clay, limestone; It is mainly used for cement, chemical, metallurgical, building materials industries. Its advantages are as follows: high dry capacity, smooth rotation, and low energy consumption, easy operation, high output and so on.

Advantages of rotary dryer: 1.Three drum dryer use telescope-feed structure, dry the material quickly. 2.Simple design, self-insulation, improve the heat efficiency to exceed 80%. 3.Structure delicate, stable operation. 4.good drying performance, coal consumption <8kg when drying 1 ton material. 5.The fuel can be coal, oil, natural gas etc, dry mass, granule and powder material. 6.Reduce land area for 50% compared to single drum rotary dryer, so construction investment is saved 50%power consumption saved 60%. 7.Finished product moisture can be adjusted depends on requirement of client. 8.Lower outlet tempreture, loonger dust removal using life. 9.Drive by tug not gear. 10.Finished product tempreture lower than 60°C, packing can be done continuously. Main technical parameters of rotary drying machine:

Model | The Diameter (mm) | The Length (m) | Slope(°) | Speed (r/min) | Power (kw) | Volume (m3) |

0.6×8-12 | 600 | 8-12 | 3-5 | 8 | 4 | 2.26 |

0.8×10-10 | 800 | 10-12 | 3-5 | 7.2 | 4 | 5.02 |

1.0×10-12 | 1000 | 10-12 | 3-5 | 6.73 | 5.5 | 7.85 |

1.2×12-18 | 1200 | 12-18 | 3-5 | 5.8 | 11-15 | 13.31 |

1.5×12-18 | 1500 | 12-18 | 3-5 | 4.8 | 15-22 | 21.2 |

1.8×12-18 | 1800 | 12-18 | 3-5 | 3.2 | 185-30 | 48.22 |

2.2×12-22 | 2200 | 12-22 | 3-5 | 3 | 22-30 | 70.43 |

2.8×15-24 | 2800 | 15-24 | 3-5 | 2.59 | 30-55 | 147.8 |

Details of rotary drying machine:

Our factory: Zhengzhou Huahong Machinery Equipment Co., Ltd. is a professional mining machine manufacturer with decades of years' experience. Our main product are grinding mills, Crushers,Dryer,Ball Mill, Sand making&washing machines, vibrating screens, etc Why Choose Us: We are the manufactory, we can provide you ex-factory price; Strictly quality control system; Professional technical online service; Any mail or message will be replied within 8 hours; Completive manufactory price; We have many large ore dressing line; We will provide equipment operation training for our client; We have a professional after-sale service team to promptly solve your problems.

Our service: Mining machines design and manufacture.

Technical engineer is available to the construction site for installation instruction and trial operation.

Customization is available.

Send your inquiry to this supplier

Send Inquiry