1 / 5

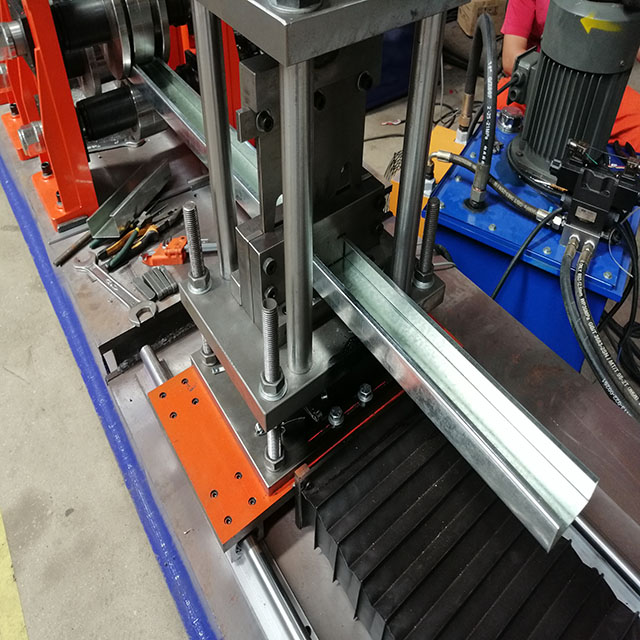

Metal U Tile Roofing Panel Machine

| Color : | Customized |

|---|

Product description

Product Description

Detailed Images

It can decide cut panel dimension according to the hydraulic drive and PLC computer control system

Hydraulic Station

1. Power: depends on final design

2. Hydraulic oil: 46# hydraulic oil

3. Working pressure: 12-16Mpa adjustable

4. Solenoid valve: 1groups

5. Color: as customer's request

1. Material: high grade NO.45 forged steel.

2. Roller station: 11(depends on final design)

3. Thickness of feeding material:1-3mm

Automatic Control System

1. Screen: touch screen or text screen

2. Automatic length measurement

3. Automatic quantity measurement

4. Computer is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved.

5. Length inaccuracy can be amended easily.

Manual Uncoiler

2 Steel coil width: 100-200mm

3 Coil placement in the coil holder: hydraulic hoist

4 Working speed: 0-15m/min adjustable

Receiving Table

It is used for transmitting and collecting the finished products

Our Service

* Help clients design profile or optimize base on our engineer suggestion

* View our Factory.

After-sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing&Delivery

Packing Details:

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

Delivery Time:

a. Two decades professional cold steel forming equipments manufacturer

Main products: glazed tile roll forming machine, ridge cap roll forming machine, corrugated roll forming machine, most popular color steel roll forming machine, double deck color steel roll forming machine, keel roll forming machine, C/Z purlin forming machine, Austalia style roller shutter door forming machine and etc.

b. National GB/T, CE and ISO9001:2008 standard

c. Business relationship with customers from more than 30 countries and areas

Customer Visit

Send your inquiry to this supplier