1 / 6

Magnetic Separator by Wet Method for Ores, Mineral, Silica Sand

Get Latest Price

Send Inquiry

| Model No. : | Btpb 2000*3000 Serise High Gradient Plate-Type |

|---|

Zibo Hemei Magnetic Materials Co., Ltd.

You might also like

Product description

Model NO.: Btpb 2000*3000 Serise High Gradient Plate-Type

Energy Saving: Energy Saving

Warranty: 1 Year

Color: Yellow

Customized: Customized

Condition: New

Hi Magnetic Intensity: 10000-18000GS

Capacity: 18-20t/H

Trademark: Hemei

Transport Package: Wooden Case by Sea

Specification: Depend on Model

Origin: Shandong China

HS Code: 8474100000

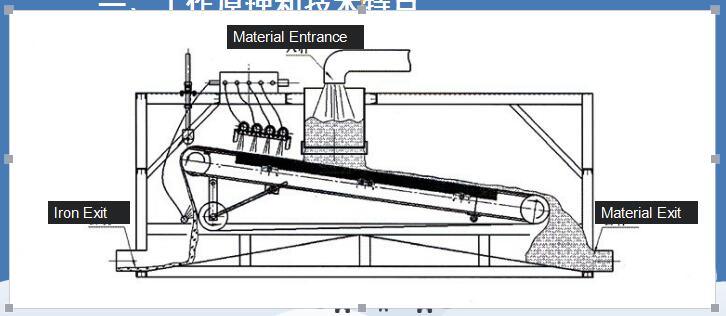

BTPB Series High Gradient Plate-Type Magnetic Separator

Application:

It is applicable to beneficiate the weakly magnetic ore and remove the iron impurities from the non-metallic ore, such as mica powder, quartz sand, potassium, feldspar, nepline, fluorite, sillimanite, spodumene, kaoline, manganeseore, weak magnetite, pyrrhotite, calcined ore, ilmenite, hematite, limonite, siderite, chromite, wolframite, columbite-tantalite, red mud. It also can be used in iron-removal operation of coal, non-magnetic ore and building materials, etc.

Technical Feature:

- Strong magnetic field intensity; suitable for the conveying belt, excellent iron separation effect.

- Automatic and continuous unloading iron, saving manpower, reliable operation.

|

Model |

Width (mm) |

Length (mm) | Magnetic Intensity (Gs) |

Capacity (t/h) |

Driving Power (KW) |

Dimension (mm) |

||||

| W1 | L1 | L | H |

W | ||||||

| BTPB600*1200 | 600 | 1200 | 10000 - 18000 |

2-3.5 | 1.1 | 600 | 1200 | 1800 | 1000 | 1000 |

| BTPB600*2000 | 600 | 2000 | 4-7 | 2.2 | 600 | 2000 | 3000 | 1200 | 1000 | |

| BTPB900*1200 | 900 | 1200 | 3-5 | 1.5 | 900 | 1200 | 1800 | 1500 | 1500 | |

| BTPB900*2000 | 900 | 2000 | 6-8 | 2.2 | 900 | 2000 | 2600 | 1800 | 1500 | |

| BTPB1200*1500 | 1200 | 1500 | 5-7 | 2.2 | 1200 | 1500 | 2400 | 1800 | 1500 | |

| BTPB1200*2400 | 1200 | 2400 | 7-9 | 2.2 | 1200 | 2400 | 3000 | 2100 | 1800 | |

| BTPB1500*2400 | 1500 | 2400 | 10-12 | 3 | 1500 | 2400 | 3000 | 2100 | 2100 | |

| BTPB1500*3000 | 1500 | 3000 | 12-14 | 3 | 1500 | 3000 | 4500 | 2800 | 2100 | |

| BTPB1800*2400 | 1800 | 2400 | 13-15 | 4 | 1800 | 2400 | 3000 | 2100 | 2400 | |

| BTPB1800*3000 | 1800 | 3000 | 15-17 | 4 | 1800 | 3000 | 4500 | 2800 | 2400 | |

| BTPB2000*2000 | 2000 | 2000 | 12-16 | 4 | 2000 | 2000 | 2800 | 1800 | 2600 | |

| BTPB2000*3000 | 2000 | 3000 | 18-20 | 5.5 | 2000 | 3000 | 4500 | 2800 | 2600 | |

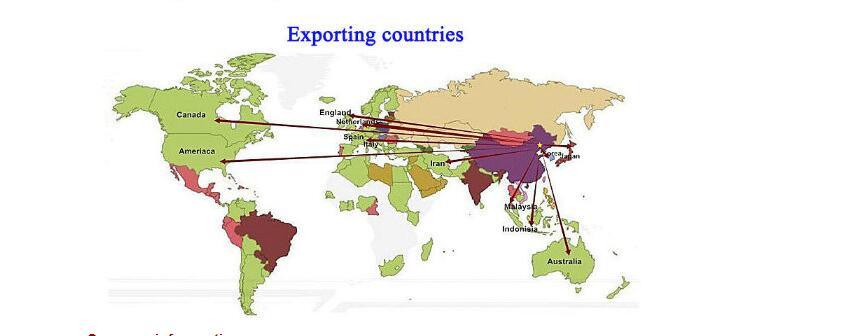

Choose HeMei 4 reasons:

FAQ

1.What is the MOQ of your machine?

A:Our MOQ is 1 set

2.How long is the machine warranty period?

A:The product warranty period is 12 months

In order to give you the responsible quotation, pls kindly inform us the following details:

1.What kind of material you are going to deal with?

2.What's the granularity of the material?

3.What's the producing capacity you are going to achieve?

Most suitable machine would be recomended to you according to your information.

Model Selection Guide

Choosing magnetic separator correctly should consider the iron content,the iron removal requirement,working environment and the technical data of the magnetic separator itself.

When the iron content is very much in the material,should choose the continuous Self-cleaning Electromagnetic Separator,Permanent magnetic separator.(RCDC, RCDD, RCDF, RCYC, RCT, CFLT series).

3.When the iron content is not too much in the material,should choose the Manual Cleaning Electromagnetic separator or Permanent magnetic separator. (RCDA RCDB RCDE and RCY series) Reducing the suspension height appropriately can remove the iron better.

4. Working in the serious dust environment,should choose complete sealed structure magnetic separator,such as RCDB,RCDZ, RCDE,RCDD, RCDF series Electromagnetic separator or RCYB,RCYD series permanent magnetic separator.

5.when the electricity power capacity is limited,appropriate to choose permanent magnetic separator.

6.When the magnetic separator installed in the front of the conveyor, the material with impact force and in the condition of loose, the material of the driving wheel (which is in bottom of the magnetic separator ) should be non ferromagnetic materials

7. When the magnetic separator installed in the middle of the conveyor,to improve the effect of iron removal,can add a WCG series non ferromagnetic straight roller under the belt.

8.If material contains non ferromagnetic metal material which can't be attracted by the magnetic separator,should install the GJT(JYG) series metal detector to test,alarm,pick the metal out manually after stop the machine.

9.Magnetic separator has below feature:

Remove the big and long iron easier than small and short piece, romove the sharp shape iron easier than the round piece,Remove the iron in the condition of moving easier than rest.In the environment with high standard of iron removal,should choose high performance magnetic separator or adopt multilevel magnetic separator.

When choosing the multilevel magnetic separator,the magnetic separator in the back should be higher in iron removal performance than the magnetic separator in the front.Or, the magnetic separator in the back will be lower efficiency in iron removal.

When the iron content is just a little in the material,adopting GJT(JYG)series metal detectors to use accompany with the strong excitation electromagnetic separator,can save electricity powder and work well in iron removal.

12.There are many methods of iron removal to magnetic materials,if the situation is complicated,please contact with our technical department,we can design the magnetic separator specially according to your special work environment.

Note: The machine dimension and Data in this Catalog just for your reference of choosing the model.

Ordering instructions

Please specify below content when ordering to our company :

1.Name of equipment, specifications, quantity and special requirements.

2.Delivery time, place, receiving company, the delivery method.

3.The user's width of belt conveyors , belt speed, Angle, material properties, particle size, moisture, thickness, the iron particle size, properties, environment temperature, humidity, dust conditions and the installation position space size.

4.Detailed address, phone, fax and invoice information.

Contact Us:

ZIBO HEMEI MAGNETIC MATERIALS CO., LTD

ZIBO MEGO INTERNATIONAL TRADE CO.,LTD

ADD: Rm1801, Flat E, ChuangYe HuoJu Square, No.111,LiuQuan RD.,Zibo, Shandong, China

TEL: 0086-533-5207762 FAX: 0086-533-8170762

Mobile Phone: 0086-18615127327

Website: www.hemeicc.com

Send your inquiry to this supplier

Send Inquiry