1 / 1

Magnesium Cast Protection Cover

| Model No. : | LM-15J009 |

|---|---|

| Brand Name : | LEMA |

Product description

Magnesium Cast Protection Cover worked for the cutter machine

Now every country optimistic about the prospect of the magnesium alloy die casting parts,especially in auto,aviation,telecom,transportation and mechanical industry, which adopt to use magnesium alloy die casting to replace steel casting for reducing weight effectively and then can save energy and reduce environment pollution. The car can decrease 0.4L oil consumption per kilometer if it can relieve every 100KGS. So America,Japan and European countries have enlarge use of magnesium alloy die casting parts, for example, steering wheel, instrument panel, seat skeleton, crankcase, gearbox shell, wheel hub and so on. So magnesium alloy die castings grows at 20%~30% a year, 80% of them are die casting parts. Meanwhile magnesium alloy die castings expand use in appliance light industry and daily hardware, such as notebook shell, VCR box, mobile phone, power tool shell,camera shell, upholstery, mower shell etc. These magnesium alloy die casting parts with a series of advantages, not only greatly reduce weight, but also have the precise & steady dimension and smooth finish surface.

Casting Magnesium Protection Housing material:

Magnesium and aluminum have big differences in the chemical, physical properties, mainly in terms of chemical reactivity, surface oxidation of the liquid metal

material tightness, thermal effects during solidification, resistant to electricity chemical corrosion resistance capabilities.

Magnesium has a strong chemical reactivity than aluminum and the metal bath surface can not be formed as dense as molten aluminum alloy oxide protective film

to prevent oxidation reaction to proceed, so magnesium alloy flammable or explosive. Magnesium alloy is also easy to dissolve other metals, including magnesium

alloy severely reduce the ability of anti-electrochemical corrosion of nickel, copper and other elements. In addition, the same volume of liquid aluminum and magnesium alloy during solidification.

Magnesium alloy heat release was significantly lower than aluminum.

The commonly used magnesium alloy die cast material

Common cold chamber die casting machine injection parts must be improved to meet the needs of the Mg die-casting shield production as follows:

1) Fast injection speed increased from 4~5m/s to 6~10m/s.

2) Reduce the time of supercharging and build pressure.

3) Improve the injection speed and injection force control.

4) Equipped with a special furnace protection gas device

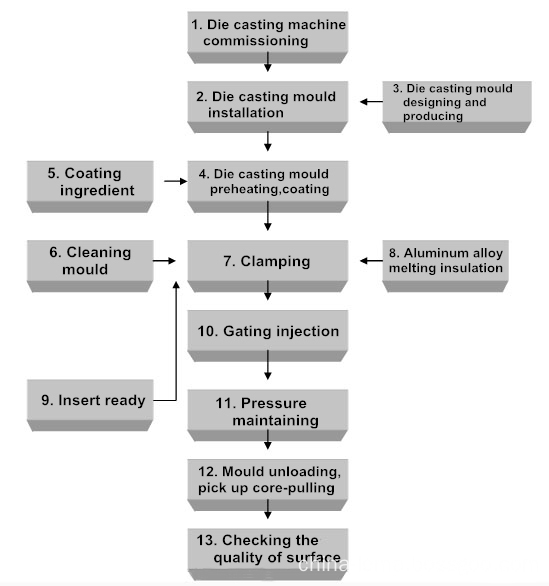

The Protection Magnesium Injection Cover production flow chart

The precision of the Magnesium Die Casting shield: ±0.1mm;

Smoothness of surface of rough part: Ra1.6;

Shrinkage rate of Magnesium alloy Die-Casting shield: 0.5%;

Material wastage rate: 5%;

General Mg die-casting shield machining allowance: 0.5mm~0.6mm;

Surface preparation methods: Sand blasted, Shot blasting, Powder coating.

The production of Magnesium Cast Protection Cap and QC control

Send your inquiry to this supplier