1 / 6

Light Ceramic Structured Packing

| Model No. : | Ceramic structured packing |

|---|---|

| Brand Name : | XINGFENG |

Product description

Type | Specific surface m2/m3 | Bulk density kg/m3 | Void % | Obl. angle | Pressure drop (mmHg/m) | Theo. plate (m-1) | Hydraulic diameter (mm) | Liquid load (m3/m2h) | Max. Factorm/s (Kg/m3)-1 |

125Y | 125 | 320 | 90 | 450 | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

160Y | 160 | 370 | 85 | 450 | 2 | 2 | 15 | 0.2-100 | 2.8 |

250Y | 250 | 420 | 80 | 450 | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

350Y | 350 | 470 | 78 | 450 | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

400Y | 400 | 500 | 75 | 450 | 3 | 3 | 8 | 0.2-100 | 2.0 |

450Y | 450 | 520 | 72 | 450 | 4 | 4 | 7 | 0.2-100 | 1.8 |

550Y | 550 | 620 | 74 | 450 | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

700Y | 700 | 650 | 72 | 450 | 6 | 7 | 5 | 0.15-100 | 1.3 |

100X | 100 | 280 | 92 | 300 | 1.5 | 1 | 30 | 0.2-100 | 3.5 |

125X | 125 | 300 | 90 | 300 | 1.8 | 1.5 | 28 | 0.2-100 | 3.2 |

160X | 160 | 350 | 85 | 300 | 2 | 1.8 | 15 | 0.2-100 | 3.0 |

250X | 250 | 380 | 80 | 300 | 2.5 | 2.3 | 12 | 0.2-100 | 2.8 |

350X | 350 | 450 | 78 | 300 | 3 | 2.5 | 10 | 0.2-100 | 2.6 |

400X | 400 | 480 | 75 | 300 | 4 | 2.8 | 8 | 0.2-100 | 2.2 |

450X | 450 | 500 | 72 | 300 | 4.5 | 3-4 | 7 | 0.2-100 | 2.0 |

470X | 470 | 440 | 75 | 300 | 5 | 5 | 7 | 0.2-100 | 1.8 |

550X | 550 | 620 | 74 | 300 | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

700X | 700 | 650 | 72 | 300 | 6 | 7 | 5 | 0.15-100 | 1.3 |

Item | Value |

Specific gravity(g/cm3) | 2.5 |

Water absorption(wt%) | ≤0.5 |

Acid resistance(wt%) | ≥99.5 |

Loss in burn(wt%) | ≤5.0 |

Max. operating Temp.(℃) | 800 |

Crush strength(Mpa) | ≥130 |

Moh’s Hardness(Scale) | ≥7 |

Al2O3 | SiO2 | Fe2O3 | CaO | MgO | K2O+Na2O | other |

17-23% | >70% | <1.0% | <1.0% | <0.5% | <3.5% | <1% |

Company Information

Company Information

Certifications

Certifications  Payment & Shipping

Payment & Shipping  Packaging & Shipping

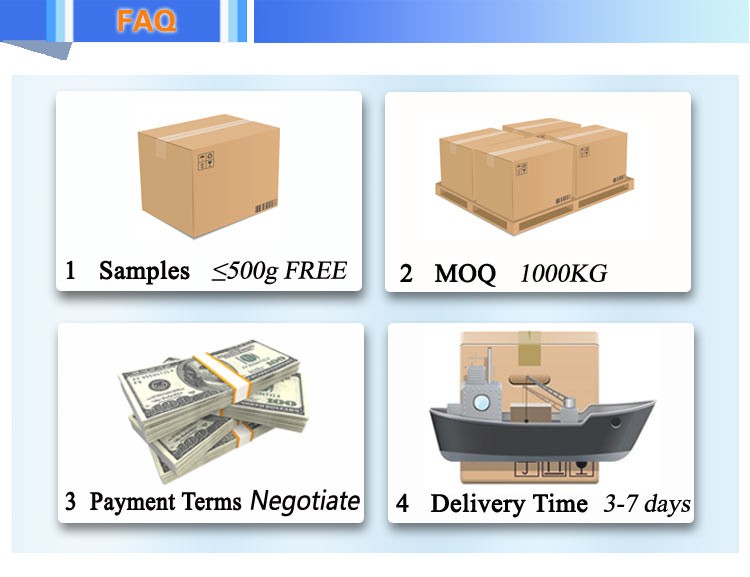

Packaging & Shipping  FAQ

FAQ  Back to home

Back to home

Send your inquiry to this supplier