1 / 5

lathe parts BT40 GSK tool holder

$21.78

≥1 Piece/Pieces

| Model No. : | BT40-GSK Tool Holders |

|---|---|

| Brand Name : | CHONGDE |

| place of origin : | China |

Jining, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Product description

BT30/40 GSK Collet Chuck CNC Machine Tool Holder

high quality lathe parts BT40 GSK tool holder

BT GSK Collet Chuck: Mainly used for clamping of straight shank tools and tools such as drills, milling cutters and taps.

BT GSK Tool Holders Spring chuck model: divided into GSK6, GSK10,GSK13,GSK16,GSK20,GSK25.

ChongDe is a manufacture in R&D,production,sales and services with ISO9001 certificate.

The main products are precision tool holder,clamping collet,pull stud,nut,spanner and other machine tool accessories with the standards of ISO,DIN,ANSI/ASME,JIS and local GB,etc.

Attaching importance to the reserch and products,we employs many experienced and skilled technicians,so that precision machining can be made according to samples or drawings.

We are specialized in researching,producing and developing many kinds of collets,CNC Machine Tool Holder, ER nuts,ER spanners,machine vises,fasteners etc. With high quality and full varieties.

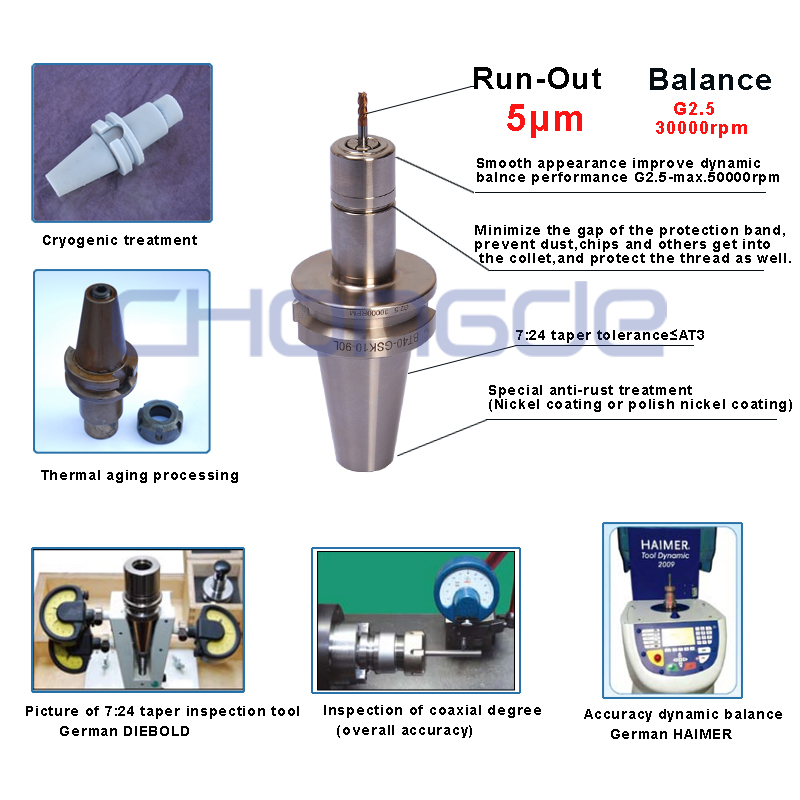

Surface roughness is reduced ,precision stability improved.

The collet chuck surface uneven texture,after polishing,the surface roughness can be leveling ,smooth and shining surface.At the same time filling surface pores scratches and other surface defects,thus improve the fatigue strength,corrosion resistance increase.

Don't influence precision.

Chuck surface is coated ,the layer is evenly ,Chemical plating solution dispersion degree of almost 100%,nickel layer is thin ,thickness is about 3u-5u,this special coating can reduce Spindle abnormal wear and tear ,Don't influence precision.

Anti-rust,anti-corrosion,durability better.

Coating adhesiion strong,enhance hardness,and anti-rust better in different surroundings,such as acid,alkali,ammonia,salt etc.Overall nickel coating ,including inside and outside cone,even if you do not take any anti-rust actiions ,it will not rust either,don't influence processing precision and spindle.Improve cleanness,precision more stable,surface more smooth,feel more comfortable and appearance nicer.

1.Package: plastic boxes and also can pack according to your requests.

2.Delivery time:Sample within 7 days and others 35 days.

I Fast reply

II Favourable price

III High quality products

IV Fast delivery

V Good after-sales service

1.Are you factory or Trade Company?

We are industry and trade integration.

2.Could you supply samples?

Yes ,free samples for some products.

3.Where do you export?

The whole world.

4.Could you produce non-standard products?

Yes ,we can .Please supply samples or drawing.

5.What are the shipping ways?

By intemational express,by air ,by sea are all OK.

6.Do you have minimum order quantity?

Conventional Products don't have.The minimum order quantity of non-standard products is 50pcs.

7.What's your delivery time?

Less than 25 days after order confirmed.

Jining, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier