1 / 1

Large scale canola oil processing line cooking oil mill plant

Get Latest Price

Send Inquiry

| Model No. : | HTKD SV |

|---|---|

| Brand Name : | Kingdo soybean oil making production line |

Henan Hi-tech Kingdo Industrial Co., Ltd.

You might also like

Product description

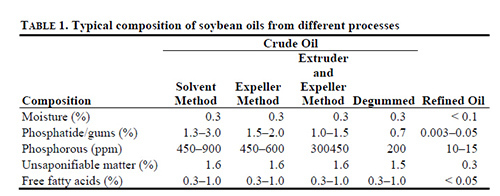

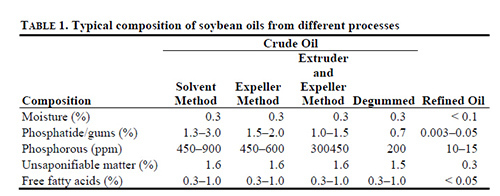

Large scale canola oil processing line cooking oil mill plant Company Information 1. About Kingdo a. 20 years manufacturing, sales and installation experience on oil process project. b. Associated with Henan University of Technology for processing design and new technology development. c.38 technical engineers research on new efficient processing craft and instruct manufacturing and installation. d.78 technicians-professional installation team-with rich and mature installation and training experience. e. CE and ISO9001 2. What's kind of equipment Hi-Tech Kingdo offers: Raw material and finished Oil products Storage equipments 1. Oil seeds pretreatment and press production line: 5-4000T per 24 hrs 2. Solvent extraction production line: 10-4000T per 24 hrs 3. Edible oil refinery production line: 1-600T per 24 hrs 4. Oil fractionation engineering 5. Biodiesel production line: 1-600T per 24 hrs Production Flow Technology and processing of soybean oil plant of large capacity Soybean seeds contain an average of 17 percent to 20 percent oil. The most popular method for recovering soy oil is solvent extraction. Solvent extraction is normally applied in very large capacity plants that produce commodity soy oil. TABLE 1. Typical composition of soybean oils from different processes  Technologies for Refining Soybean Oil The oil directly recovered from the soybean seeds, is “crude” and contains impurities, such as lecithins, free fatty acids, and undesirable color and odor. These impurities are removed in a series of processes that yield “refined” oil. A refining processing normally consists of below four steps: 1. Degumming to remove phosphatides: a) To produce lecithin as a valuable by-product b) To obtain degummed oil for long-term storage and transportation c) To prepare degummed oil for conventional (caustic) or physical refining 2. Neutralization with caustic soda to get rid of free fatty acids The purpose of neutralization is to eliminate the free fatty acids from the oil (see Table 1). The simplest and most common neutralization method consists of mixing calculated amounts of caustic soda to the oil so that it reacts with the free fatty acids. The soap stock formed by the action of caustic soda is allowed to settle at the bottom of the tank and is then drained 3. Bleaching and filtration to eliminate color pigments 4. Deodorization for removal of odors: The purpose of deodorizing oil is to eliminate undesirable odors. Images per each section of soybean oil processing: Buckent elevator to convey the soybean for cleaning section to remove kinds of impurities

Technologies for Refining Soybean Oil The oil directly recovered from the soybean seeds, is “crude” and contains impurities, such as lecithins, free fatty acids, and undesirable color and odor. These impurities are removed in a series of processes that yield “refined” oil. A refining processing normally consists of below four steps: 1. Degumming to remove phosphatides: a) To produce lecithin as a valuable by-product b) To obtain degummed oil for long-term storage and transportation c) To prepare degummed oil for conventional (caustic) or physical refining 2. Neutralization with caustic soda to get rid of free fatty acids The purpose of neutralization is to eliminate the free fatty acids from the oil (see Table 1). The simplest and most common neutralization method consists of mixing calculated amounts of caustic soda to the oil so that it reacts with the free fatty acids. The soap stock formed by the action of caustic soda is allowed to settle at the bottom of the tank and is then drained 3. Bleaching and filtration to eliminate color pigments 4. Deodorization for removal of odors: The purpose of deodorizing oil is to eliminate undesirable odors. Images per each section of soybean oil processing: Buckent elevator to convey the soybean for cleaning section to remove kinds of impurities  Vibrating sives

Vibrating sives  Soya-bean husker

Soya-bean husker  Solvent extaction

Solvent extaction  Soybean oil solvent extraction 2

Soybean oil solvent extraction 2  Soya-bean oil solvent extraction 3

Soya-bean oil solvent extraction 3  Soyabean oil solvent extraction-4

Soyabean oil solvent extraction-4  Images of Soybean oil refinery processing Soybean oil plant refinery 1

Images of Soybean oil refinery processing Soybean oil plant refinery 1  Soybean oil plant refinery 2

Soybean oil plant refinery 2  Soybean oil plant refinery 3 -- centrifugual machine

Soybean oil plant refinery 3 -- centrifugual machine  Soybean oil plant refinery 4

Soybean oil plant refinery 4  Images of auxiliary facility of soybean oil plant Power cabinet control room

Images of auxiliary facility of soybean oil plant Power cabinet control room  Cooling water tower

Cooling water tower  Packaging & Shipping Proffessional packaing team of soybean oil plant for overseas shipping:

Packaging & Shipping Proffessional packaing team of soybean oil plant for overseas shipping:  FAQ Any of your questions are warmly welcomed, it is Susan Chou (Skype: Susanzhou2u) here to serve you: Susan Chou (Skype:susanzhou2u) Cell (whatsapp):+86 177 03818308 Tel: +86 -371-86561185 Website:http://www.hnkingdo.com/ Henan Hi-tech Kingdo industrial Co., Ltd

FAQ Any of your questions are warmly welcomed, it is Susan Chou (Skype: Susanzhou2u) here to serve you: Susan Chou (Skype:susanzhou2u) Cell (whatsapp):+86 177 03818308 Tel: +86 -371-86561185 Website:http://www.hnkingdo.com/ Henan Hi-tech Kingdo industrial Co., Ltd

Technologies for Refining Soybean Oil The oil directly recovered from the soybean seeds, is “crude” and contains impurities, such as lecithins, free fatty acids, and undesirable color and odor. These impurities are removed in a series of processes that yield “refined” oil. A refining processing normally consists of below four steps: 1. Degumming to remove phosphatides: a) To produce lecithin as a valuable by-product b) To obtain degummed oil for long-term storage and transportation c) To prepare degummed oil for conventional (caustic) or physical refining 2. Neutralization with caustic soda to get rid of free fatty acids The purpose of neutralization is to eliminate the free fatty acids from the oil (see Table 1). The simplest and most common neutralization method consists of mixing calculated amounts of caustic soda to the oil so that it reacts with the free fatty acids. The soap stock formed by the action of caustic soda is allowed to settle at the bottom of the tank and is then drained 3. Bleaching and filtration to eliminate color pigments 4. Deodorization for removal of odors: The purpose of deodorizing oil is to eliminate undesirable odors. Images per each section of soybean oil processing: Buckent elevator to convey the soybean for cleaning section to remove kinds of impurities

Technologies for Refining Soybean Oil The oil directly recovered from the soybean seeds, is “crude” and contains impurities, such as lecithins, free fatty acids, and undesirable color and odor. These impurities are removed in a series of processes that yield “refined” oil. A refining processing normally consists of below four steps: 1. Degumming to remove phosphatides: a) To produce lecithin as a valuable by-product b) To obtain degummed oil for long-term storage and transportation c) To prepare degummed oil for conventional (caustic) or physical refining 2. Neutralization with caustic soda to get rid of free fatty acids The purpose of neutralization is to eliminate the free fatty acids from the oil (see Table 1). The simplest and most common neutralization method consists of mixing calculated amounts of caustic soda to the oil so that it reacts with the free fatty acids. The soap stock formed by the action of caustic soda is allowed to settle at the bottom of the tank and is then drained 3. Bleaching and filtration to eliminate color pigments 4. Deodorization for removal of odors: The purpose of deodorizing oil is to eliminate undesirable odors. Images per each section of soybean oil processing: Buckent elevator to convey the soybean for cleaning section to remove kinds of impurities  Vibrating sives

Vibrating sives  Soya-bean husker

Soya-bean husker  Solvent extaction

Solvent extaction  Soybean oil solvent extraction 2

Soybean oil solvent extraction 2  Soya-bean oil solvent extraction 3

Soya-bean oil solvent extraction 3  Soyabean oil solvent extraction-4

Soyabean oil solvent extraction-4  Images of Soybean oil refinery processing Soybean oil plant refinery 1

Images of Soybean oil refinery processing Soybean oil plant refinery 1  Soybean oil plant refinery 2

Soybean oil plant refinery 2  Soybean oil plant refinery 3 -- centrifugual machine

Soybean oil plant refinery 3 -- centrifugual machine  Soybean oil plant refinery 4

Soybean oil plant refinery 4  Images of auxiliary facility of soybean oil plant Power cabinet control room

Images of auxiliary facility of soybean oil plant Power cabinet control room  Cooling water tower

Cooling water tower  Packaging & Shipping Proffessional packaing team of soybean oil plant for overseas shipping:

Packaging & Shipping Proffessional packaing team of soybean oil plant for overseas shipping:  FAQ Any of your questions are warmly welcomed, it is Susan Chou (Skype: Susanzhou2u) here to serve you: Susan Chou (Skype:susanzhou2u) Cell (whatsapp):+86 177 03818308 Tel: +86 -371-86561185 Website:http://www.hnkingdo.com/ Henan Hi-tech Kingdo industrial Co., Ltd

FAQ Any of your questions are warmly welcomed, it is Susan Chou (Skype: Susanzhou2u) here to serve you: Susan Chou (Skype:susanzhou2u) Cell (whatsapp):+86 177 03818308 Tel: +86 -371-86561185 Website:http://www.hnkingdo.com/ Henan Hi-tech Kingdo industrial Co., Ltd Send your inquiry to this supplier

Send Inquiry