Video

1 / 4

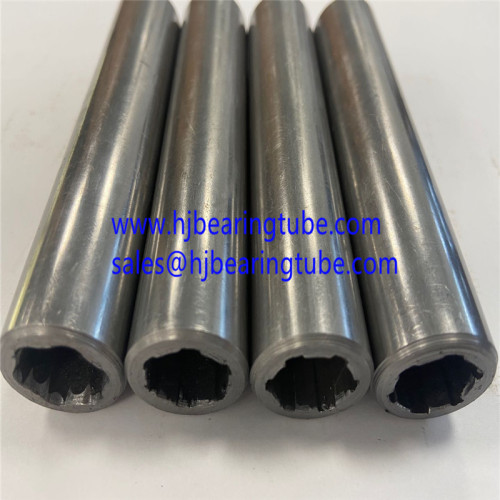

Irregular Shaped Metal Tubing Seamless carbon Steel Tubing

| Model No. : | irregular steel tubing |

|---|---|

| Brand Name : | Huijie |

| Usage : | Special Purpose |

Ningbo, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Irregular Shaped Metal Tubing Seamless carbon Steel Tubing

Specification:JIS G3445 STKM11A STKM12C STKM13C outer round inner oval shapped steel tubes for auto rubber bushing

ASTM A519 SAE1010,SAE1020,SAE1026,SAE4130,SAE4140

DIN2391 St37 St52 St44/EN10305-1 E215+N E235+N E355+N

Seamless Carbon and Alloy Steel Mechanical Tubing

Applications: For auto rubber bushing

Size range: O.D.:6-168mm W.T.:1-15mm L:max12000mm

Steel Grade JIS G3445 STKM11A,12C,13C or others,Chemical compisition:

Mechanical properties:

| JIS3445 | C | Si | Mn | P | S | Nb or V | Tention Test | Flateniug | Bendability | ||||

| Symbol |

T.S. N/mm^2 |

Y.P. N/mm^2 |

Elongation | ||||||||||

|

No 4,11,12 Test pe |

No 4,5 Test pe |

Distance Between Flatened Plates |

Band Angle |

Inside Radius |

|||||||||

| STKM11A | 0.12 max. | 0.35 max. | 0.60 max. | 0.040 max. | 0.040 max. | . | 290 min. | . | 35 min. | 30 min. | 1/2D | 180 | 4 D |

| STKM12A | 0.20 max. | 0.35 max. | 0.60 max. | 0.040 max. | 0.040 max. | . | 340 min. | 175 min. | 35 min. | 30 min. | 2/3D | 90 | 6 D |

| STKM12B | 390 min. | 275 min. | 25 min. | 20 min. | 2/3D | 90 | 6 D | ||||||

| STKM12C | 470 min. | 355 min. | 20 min. | 15 min. | . | . | . | ||||||

| STKM13A | 0.25 max. | 0.35max. | 0.30 to 1.00 | 0.040 max. | 0.040 max. | . | 370 min. | 215 min. | 30 min. | 25 min. | 2/3D | 90 | 6 D |

| STKM13B | 440 min. | 305 min. | 20 min. | 15 min. | 3/4D | 90 | 6 D | ||||||

| STKM13C | 510 min. | 380 min. | 15 min. | 10 min. | . | . | . | ||||||

| STKM14A | 0.30 max. | 0.35 max. | 0.30 to 1.00 | 0.040 max. | 0.040 max. | . | 410 min. | 245 min. | 25 min. | 20 min. | 3/4D | 90 | 6 D |

| STKM14B | 500 min. | 355 min. | 15 min. | 10 min. | 7/8D | 90 | 8 D | ||||||

| STKM14C | 550 min. | 410 min. | 15 min. | 10 min. | . | . | . | ||||||

| STKM15A | 0.25 to 0.35 | 0.35 max. | 0.30 to 1.00 | 0.040 max. | 0.040 max. | . | 470 min. | 275 min. | 22 min. | 17 min. | 3/4D | 90 | 6 D |

| STKM15C | 580 min. | 430 min. | 12 min. | 17 min. | . | . | . | ||||||

| STKM16A | 0.35 to 0.45 | 0.40 max. | 0.40 to 1.00 | 0.040 max. | 0.040 max. | . | 510 min. | 325 min. | 20 min. | 15 min. | 7/8D | 90 | 8 D |

| STKM16C | 620 min. | 460 min. | 12 min. | 7 min. | . | . | . | ||||||

| STKM17A | 0.45 to 0.55 | 0.40 max. | 0.40 to 1.00 | 0.040 max. | 0.040 max. | . | 550 min. | 345 min. | 20 min. | 15 min. | 7/8D | 90 | 8 D |

| STKM17C | 650 min. | 480 min. | 10 min. | 5 min. | . | . | . | ||||||

| STKM18A | 0.18 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | . | 440 min. | 275 min. | 25 min. | 20 min. | 7/8D | 90 | 6 D |

| STKM18B | 490 min. | 315 min. | 23 min. | 18 min. | 7/8D | 90 | 8 D | ||||||

| STKM18C | 510 min. | 380 min. | 15 min. | 10 min. | . | . | . | ||||||

| STKM19A | 0.25 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | . | 490 min. | 315 min. | 23 min. | 18 min. | 7/8D | 90 | 6 D |

| STKM19C | 550 min. | 410 min. | 15 min. | 10 min. | . | . | . | ||||||

| /D | 0.25 max. | 0.55 max. | 1.60 max. | 0.040 max. | 0.040 max. | 0.15 max. | 540 min. | 390 min. | 23 min. | 18 min. | 7/8D | 90 | 6 D |

1. Thickness variation can’t lead the wall out the limit deviations concerning wall thickness.

2. In pipe cross-section the deviation from right angle can’t be more than ±1.5°.

3. Pipe curvature can’t be more than 2 mm for 1m of length.

Pipes are produced without adjustment, in this case curvature is not regulated.

|

Tolerances on OD |

|

|

Division |

Tolerance on OD |

|

No.1 |

under 50mm ±0.5mm

50mm or over ±1%

|

|

No.2 |

under 50mm ±0.25mm

50mm or over ±0.5%

|

|

No.3 |

under 25mm ±0.12mm

25mm or over to and excel.40mm ±0.15mm

40mm or over to and excel.50mm ±0.18mm

50mm or over to and excel.60mm ±0.20mm

60mm or over to and excel.70mm ±0.23mm

70mm or over to and excel.80mm ±0.25mm

80mm or over to and excel.90mm ±0.30mm

90mm or over to and excel.100mm ±0.40mm

100mm or over ±0.50%

|

Note:1. For hot finished seamless steel tube, the outside diameter tolerance No.1 shall be applied.

2.The tolerance on outside diameter of quenched and tempered tubes shall be as agreed upon by the purchaser and manufacturer.

|

Tolerances on WT |

|

|

Division |

Tolerance on WT |

|

No.1 |

under 4mm +0.6mm -0.5mm

4mm or over +15%-12.5%

|

|

No.2 |

under 3mm ±0.3mm

3mm or over ±10%

|

|

No.3 |

under 2mm ±0.15mm

2mm or over ±8%

|

Tags:rubber bushing oval tubes ,Shape oval pipes,cold drawn hexagon profile tubes,Oval steel tubes

Irregular metal tubing,Irregular hollow section,irregular steel tubing

Video

Ningbo, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier