Video

1 / 7

Industrial tray dryer Chemical materials drying oven

Options:

- CT-C

| Model No. : | CT-C |

|---|---|

| Brand Name : | Bole Tech |

| species : | Drying Oven |

Changzhou, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Product description

Description of tray dryer

Hot air circulating oven / Tray dryer is equipped with low-noise and thermostable axial flow fan and automatic temperature control system. The entire circulatory system is sealed, improving the thermal efficiency of oven from traditional 3-7% in drying room to the current 35-45%, with the highest thermal efficiency up to 50%. The design success of GR hot air circulating oven make our hot air circulation oven has reached the advanced level at home and abroad. It has saved a lot of energy for our country and improved the economic efficiency of enterprises.

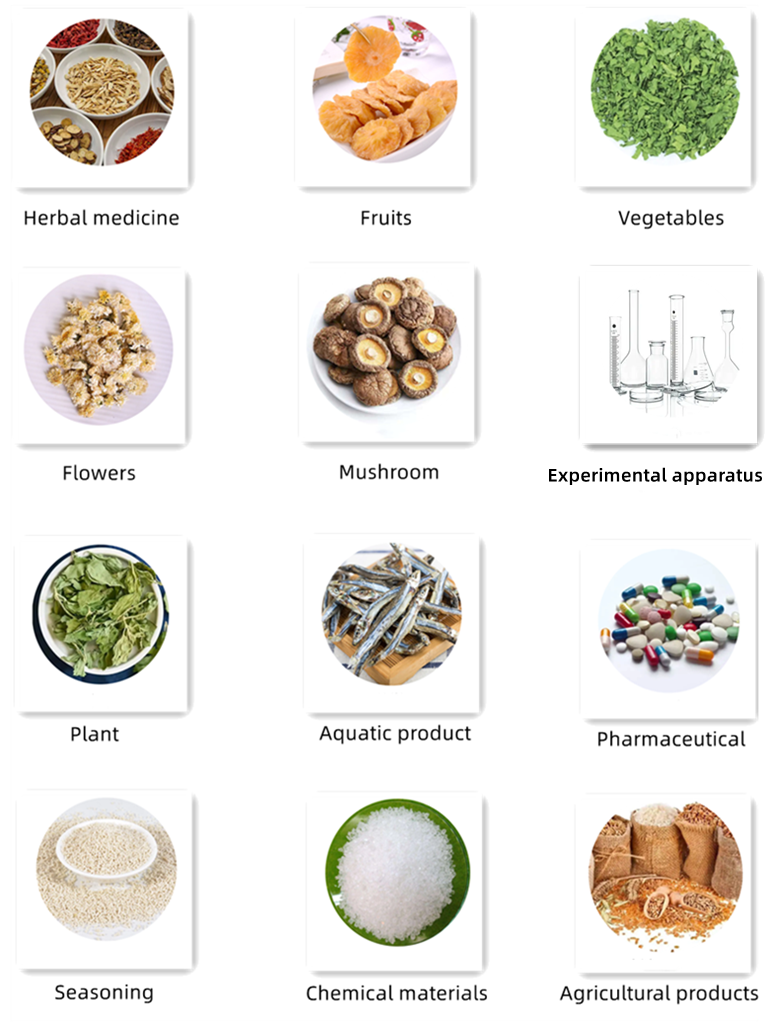

This equipment is mainly used in drying fish, medicine, sesame, vegetables, fruit, seafood, flowers, such as ginseng, red ginseng, ginseng, angelica, cordylines sinensis, honeysuckle, conventional, schisandra, astragalus and konjac, yam, maize seed, tobacco seeds, pumpkin, onion, spinach, brake, wild, carrots, celery, cowpea, chili, beans, tomatoes, mushrooms, mushrooms, agaric, garlic, ginger, raisins, kiwi fruit, banana, litchi, longan, apple, hawthorn, persimmon, scallops, dried fish, kelp, vinasse, chrysanthemum, rose dry food processing, etc.

In drying process, fresh cold air is sucked into the drying chamber by the circulation fan and flows through the steam radiator or electrical heating tubes installed at the top to get required temperature. With the help of air distributor, the hot air evenly flows through each layer of trays for heat transfer and carries way the evaporated moisture. Most of the damp air flows back to the circulation fan for next drying circulation while part of the damp air is exhausted for energy saving. The drying process is batch type. When the drying is finished, open the chamber door and pull out the trolleys for unload the dried product.

Features of tray dryer

1. Most of the air is circulated inside the oven, with high hot efficiency, and the energy can be saved;

2. The usage of forced ventilation, adjustable sub-box with the wind plates, can dry materials evenly;

3. The noise of our machine is slow and low, and has a temperature control box;

4. Using our machine can dry a lot of materials with different shapes, it can meet your different needs.

Parameters of tray dryer

|

Model

|

CT-C-O

|

CT-C-I

|

CT-C-II

|

CT-C-III

|

CT-C-IV

|

|

Effective volume (m3)

|

1.3

|

2.6

|

4.9

|

7.4

|

10.3

|

|

Evaporation area (m2)

|

7.1

|

14.1

|

28.3

|

42.4

|

56.5

|

|

Capacity (kg/batch)

|

60

|

120

|

240

|

360

|

480

|

|

Power of fan (kw)

|

0.55

|

0.55

|

0.55*2

|

0.55*3

|

0.55*4

|

|

Area of steam radiator (m2)

|

15

|

23

|

48

|

72

|

96

|

|

Steam consumption (kg/h)

|

15

|

20

|

40

|

60

|

80

|

|

Electrical heater (kW)

|

9

|

15

|

30

|

45

|

60

|

|

Quantity of trolley (pcs)

|

1

|

2

|

4

|

6

|

8

|

|

Quantity of tray (pcs)

|

24

|

48

|

96

|

144

|

192

|

|

Size of equipment

(mm)

|

1380×1200

×2000

|

2260×1200

×2000

|

2260×2200

×2000

|

2260×3200

×2000

|

4280×2200

×2270

|

|

Weight (kg)

|

820

|

1580

|

1800

|

2100

|

2800

|

Video

Changzhou, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier