1 / 1

Industrial Grade Xanthan Gum Powder for Well Drilling

| Brand Name : | N/A |

|---|---|

| place of origin : | China |

Product description

Xanthan Gum, also known as Xanthan Gum, Hansen Gum and Xanthomonas Polysaccharide, is a monospore polysaccharide produced by Pseudoxanthomonas fermentation. Because of its special macromolecular structure and colloidal properties, it has a variety of functions and can be used as emulsifier, stabilizer, gel thickener, sizing agent, film forming agent, etc., and is widely used in various fields of the national economy. Xanthan Gum Powder is known as "industrial monosodium glutamate" and is currently a microbial polysaccharide with a large production scale and extremely wide applications in the world.

Basuc information:

Product Name: Xanthan gum

Other Names: Hansheng gum; Cyprine gum; Yellow gum

Chemical formula: C35H49O29

CAS No.: 11138-66-2

EINECS No.: 234-394-2

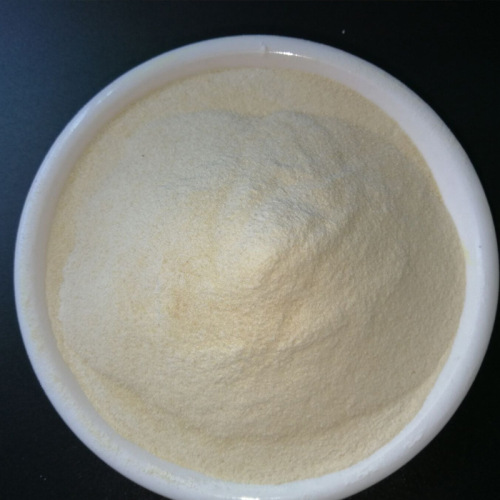

Appearance: White or light yellow powder

Structure

Xanthan gum, also known as xanthan gum or Hansheng gum, is an extracellular acidic heteropolysaccharide produced by fermentation of Xanthomonas flavus. It is a polysaccharide polymer compound composed of D-glucose, D-mannose, and D-glucuronic acid in a ratio of 2:2:1, with a relative molecular weight of over 1 million. The secondary structure of xanthan gum is the reverse winding of side chains around the main chain skeleton, which is maintained by hydrogen bonding to form a rod-shaped double helix structure.

Character

Xanthan gum is a light yellow to white flowable powder with a slight odor. Easy to dissolve in cold and hot water, neutral solution, resistant to freezing and thawing, insoluble in ethanol. Disperse and emulsify in water to form a stable hydrophilic viscous colloid.

Main uses

Used as a stabilizer, thickener, and processing aid for various purposes in industry, including making canned and bottled food, bakery food, dairy products, frozen food, salad seasoning, beverages, brewing, candy, pastry and pastry toppings, etc. When making food, it is easy to flow, pour out and in, pipeline, and reduce energy consumption.

The application of xanthan gum in the petroleum industry

One major market for xanthan gum is the petroleum industry. At present, the main chemicals used in oil fields in China are polyacrylamide, CMC, modified starch, etc., which result in high drilling costs and low oil production rates. Xanthan gum has much stronger abilities in increasing viscosity, thickening, salt resistance, and pollution resistance than other polymers, especially in drilling in oceans, beaches, high brine layers, and permafrost layers. Xanthan gum has significant effects in mud treatment, completion fluids, and tertiary oil recovery. It plays a significant role in accelerating drilling speed, preventing oil well collapse, protecting oil and gas fields, preventing blowout, and significantly improving oil recovery rates. This product has great development prospects as an ideal additive.

1. Drilling industry

Drilling fluid is the operating fluid used in the drilling process. During the drilling process, drilling fluid plays an important role, and people often compare it to the "blood of drilling". Its function is to suspend and carry rock cuttings, clean the bottom of the well; Lubricating and cooling the drill bit, increasing the drill bit depth, and impacting the formation through the water hole of the drill bit are beneficial for breaking rocks; Forming mud cakes to increase the stability of the wellbore; Establish a liquid column pressure that can balance formation pressure to prevent complex accidents such as jamming, collapse, leakage, and spraying; When using turbodrill tools, it can be used as a liquid for transmitting power. Xanthan gum is one of its main components, and its function is to increase viscosity and shear force, improve the suspension capacity of drilling fluid, which is essential for the function of drilling fluid.

2. Oil extraction industry

Among various methods to improve oil recovery, polymer flooding plays an important role. The function of polymers is to regulate the rheological properties of water injection, increase the viscosity of the driving fluid, and improve the efficiency of water flooding. Reduce the permeability of the formation water phase, allowing water and oil to flow forward at a uniform speed. This type of polymer must have excellent viscosity increasing performance under reservoir conditions, and high viscosity retention under temperature, pressure, and salt conditions. Due to its excellent viscosity, rheological properties, water solubility, chemical stability, and strong mechanical resistance to degradation, xanthan gum solution can be used as a displacement agent for oilfield development. Compared with general hydrolyzed polyacrylamide, it has stable physical and chemical properties, simple processing technology, good oil displacement effect, low manufacturing cost, and due to its good shear degradation resistance, it can selectively flow in the formation and has better oil displacement effect. It has gradually been applied as a displacement agent to improve oil recovery or a chemical profile control agent to improve production efficiency in oilfield development. Physical simulation experiments further demonstrate that xanthan gum has the effect of improving oil recovery and is a high-performance oilfield displacement agent. After completing the primary and secondary oil extraction using conventional methods, more than 50% of the oil remains in the rock and cannot be recovered. Based on economic and energy considerations, people are increasingly paying attention to improving the recovery rate of oil. The process of injecting water into oil formations is used for secondary oil extraction. However, the relative fluidity of the injected liquid and viscous crude oil still results in a large amount of dead oil residue underground. If a polymer with thickening properties is added to the injection liquid, it can reduce the fluidity of water and improve oil recovery rate. Many types of polymers can be used as flow control agents for petroleum recovery, among which xanthan gum is considered to have great potential for application. Xanthan gum has many basic conditions necessary to improve oil recovery rate.

3. Xanthan gum is also used in fracturing fluids, mainly as a thickener for water-based fracturing fluids, and has the function of reducing friction.

Send your inquiry to this supplier