Video

1 / 2

Hywell Supply Vertical Ribbon Vacuum Dryers

$12500.00

≥1 Set/Sets

| Model No. : | HW |

|---|---|

| Brand Name : | Hywell |

| species : | Vacuum Drying Equipment |

Changzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Attention to order

1. Output of Ribbon Vacuum Dryers : shift time daily.

2. Energy of Vertical Vacuum Dryers that can be supplied: steam pressure, electricity properly, fuel of coal, oil and natural gas.

3. Control requirement of Vertical Ribbon Vacuum Dryers : whether or not the inlet and outlet temperatures should be con 4.Liquid name and property: solid contents (or water contents), viscosity,

surface tension and PH value.

5. Dry powder density residual water contents allowed, particle size, and

maximum temperature allowed.

trolled.

6. Other special requirements.

Ribbon vacuum Drying Machine Advantages

Hywell

machinery HW series ribbon vacuum dryer had the following advantages over

conventional solutions.

1.

Multi-purpose and multi-processing

2. Efficient

batch drying of loose powders to heavy filter cakes and viscous liquids

3. Compact

design

4. The working

process of drying machine use intermittent operation, after the wet materials

enter into the stock bin, through the wall jacket to heat and dry the

materials. transmission shaft heating is also available, which can heat more

sufficiently.

5. Hywell

company specially designed this equipment for processing the slurry materials,

high viscosity and high-moisture material, meanwhile, the solvent from the

material needs to recovery.

6.High

efficiency:The machine is

set for drying, mixing and distillation in one of the efficient multifunctional

closed vertical vacuum drying equipment complied with GMP requirement. its

drying efficiency is as 3-5 times as the same specifications of other dryer.

7 .High mixing

precision:It can reach

high mixing uniform, Even mixing of different density and different particle

shape material in the same batch of products, can achieve the required mixing

precision in our machine. Even adding very litter materials in a large quantity

of materials, the machine can reach perfect mixing uniform.

8. Low shear

strength stirring:It adopt low

shear strength stirrer, which can gently mix the materials with low speed

rotary and energy consumption. the mixing strength and time not much.

9.Sealed design:The machine is total sealed design with all

the connections include the loading and discharge nozzle fixed, which can

fulfill the requirement of the materials and safe environment.

10.Energy

saving: Compared with traditional drying equipment, for example, bipyramid

vacuum drying machine, tray vacuum drying machine, hot air oven and so on.

1). In the same condition of volume, charge

materials can be increased more than one time.

2). In the same condition of energy

consumptions, it can be increased to two times to five times in drying

production.

3). Drying time is less than one third of

traditional drying machine.

Options

1. Ribbon Design:

We offer

several types of spiral ribbons for different sizes and applications.

2. Construction Material & Sanitary

Finishes:

We are able to

offer our Ribbon vacuum dryer with contact part to be built in Carbon steel,

SS304, SS316/316L, Titanium, Duplex stainless steel, etc. Standard of internal

and external finish can be adopted to the customer’s needs. Multiple types of

finishes are available also, including sanitary type & even

electro-polishing with proof of passivation.

3. Feeding & Discharge Options:

Screw vacuum dryer

can have a variety of feeding & discharging methods that match the demands

of the filling & production line.

4. Drive Systems:

Ribbon drying

machine have a drive system by geared motor, cycloidal reducer, worm reducer,

belt or chain transmission, etc.

5. Heating & Cooling Jackets:

Ribbon vacuum

dryer are available with jackets for heating / cooling operation.

6. Custom Engineered Dimensions:

Dimensions of

our conical screw vacuum dryer can be defined according to customer’s

requirements.

7. Ribbon Mixer Sizes:

screw vacuum

drier from 100 to 5000 lit. total volume with bigger size as per request &.

more.

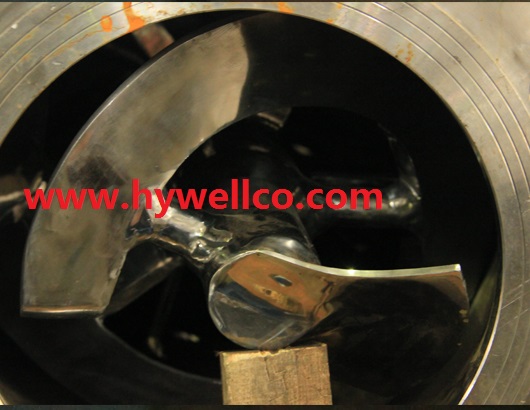

Product Description:

The is a kind of vertical

vacuum dryer worked by batch .he machine mainly consists of the barrel with the

jacket , stirring impeller ,drive system and vacuum system(if the solvent needs

recovery , it should equip with the condenser device ). The wet material in the

cylinder are stirred continuously by the stirring impeller during the working .

The heat transferring happened between the material and the inner wall of the

cylinder and make the moisture from the material is evaporated , and wet air is

pumped outside by the vacuum system.

High efficiency

The machine is set for drying, mixing and distillation in one of the efficient multifunctional closed vertical vacuum drying equipment complied with GMP requirement. its drying efficiency is as 3-5 times as the same specifications of other dryer. The loading capacity is double times as the same specifications of other dryer.

High mixing precision

It can reach high mixing uniform, Even mixing of different density and different particle shape material in the same batch of products, can achieve the required mixing precision in our machine. Even adding very litter materials in a large quantity of material such harsh conditions, the machine can reach perfect mixing uniform.

The main technical parameters of the machine are available for reference. we also produce and design product as peer customers' requirement.

|

Model |

Max load volume (L) |

Speed (r/min) |

Motor Power (KW) |

Adaptable materials |

weight (kg) |

|

HW200 |

160 |

0~60 |

2.2 |

Non- corrosive materials, Liquid, Solid-state ,etc. |

1000 |

|

HW500 |

400 |

0~60 |

3 |

1300 |

|

|

HW750 |

600 |

0~63 |

5.5 |

1600 |

|

|

HW1000 |

800 |

0~63 |

7.5 |

2000 |

|

|

HW1500 |

1200 |

0~63 |

11 |

2400 |

|

|

HW2000 |

1600 |

0~63 |

15 |

2800 |

Quality control

In order to ensure quality of product, we focus on user 's requirements and control improvement and enhancement quality of products .The quality assurance mainly focus on the processes of ensuring production readiness inspection, control of raw materials and components, process control, critical parts, important parts of quality control, assembly quality control, process control testing, measurement equipment control. Pay close attention to the implementation of the quality assurance work, strictly to three inspection system of self-checking, mutual inspection, special inspection. The key point of Quality assurance is focuses on critical parts, important parts of quality control, the quality standards required by ISO9000 quality control procurement documents in order to clarify its status and acceptance of quality standards for company's re-inspections ; For critical parts and important that the key processes of identification and corresponding technical documentation, control by "the implementation of key quality control process", and complete, accurate and complete original records. Difficulties in quality assurance is a special process control, quality assurance is mainly painting, has developed a special process (painting) process documents, take the appropriate technical measures, to quality assurance.

In the production process, we pay close attention to quality control of each process. Every component, every process was strictly controlled. Enhanced the quality inspection process, the establishment of the necessary quality control point, the process by a full-time staff and quality inspector for inspection and supervision. Improved testing procedures and operating instruction.

OUR SERVICES

Pre-sale service

We Invite customers to visit our company and

communicate on technical requirements face to face.

Sale service

Responsible for debugging the equipment

according to customers' requirements of various technical data. Our engineers

will train our customers about equipment features and operation key points to

make sure the equipment running in the best condition.

After-sale service

We provide installation, debugging,

maintenance, training and other services (Optional); Provide relevant technical

data, equipment, software and related GMP certification materials;Set up

after-sales service hotline.

Quality promise

Our company promises strictly operate the

ISO9001 quality system certification standards and pharmaceutical equipment GMP

audit requirements,promise we provide new equipment. Advanced technology,good

quality. Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year, all the

parts for the equipment choose well-known brand.During the warranty when

equipment have problem in quality like equipment failure and damage, our

company offer free maintenance or replacement.

Video

Changzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier