1 / 2

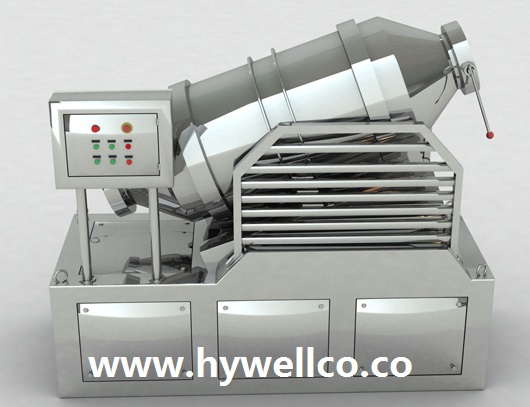

CE Approved Mixing Machinery

| Model No. : | EYH |

|---|---|

| Brand Name : | Hywell |

| Mixer Machine : | Blender |

Changzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

CE Approved Mixing Machinery

The advantages of EYH Series Big Capacity Mixing Machine

1. This High Efficiency Amylum Mixer has obtained 6 patents

2. Its capacity is 100-5000kg/batch

3. EYH Series Mixing Machinery has obtained CE certification.

4.CE Approved Mixing Machinery can use for Condiments Mixer and High Efficiency Amylum Mixer

Ahout Hywell Machinery:

We are the first company to produce mixing equipment of the most yield and the best specification (20, 000L is the maximum capacity in China). More the 90% mixing machines in Chinese market are produced by us.

Product Application:

It's widely used as the mixing machine for solid medicine powder in

pharmaceutical industry worldwide. The mixing uniformity is high, the material

vessel is movable, these are very convenient for material loading, mixing,

discharging and cleaning. It's easy to integrate with the upstream and

downstream process, the problem of cross pollution and fly-dust caused by

multi-material-transferring are solved. Various of material vessel might be

equipped with this machine, so to meet the mixing requirement of large batch

capacity, and multi-varities.

Application and feature of CE Approved Mixing Machinery:

1. The mixing machine is widely used in pharmaceutical, food, dye, fodder, chemical fertilizer and pesticide and is especially suitable for mixing various solid materials with large volume (100 to 20000 liters)

2. The mixing barrel swings while rotates so that the materials in the barrel can be fully mixed.

The Main technical datum of industrial mixing equipment is for reference. We also produce and design product according to customers' requirements.

| Model | Barrel volume(L) | Max .loading Volume(L) | Max. loading weight(kg/lot) | Total motor power(KW) | Total weight(kg) | Overall dimensions(mm) |

| EYH-300 | 300 | 180 | 90 | 1.3 | 340 | 925*905*1360 |

| EYH-600 | 600 | 360 | 180 | 2.2 | 750 | 1145*1105*1600 |

| EYH-800 | 800 | 480 | 240 | 3 | 1000 | 1305*1255*1790 |

| EYH-1000A | 1000 | 600 | 300 | 3 | 1300 | 1375*2255*1770 |

| EYH-1500A | 1500 | 900 | 450 | 4.4 | 1750 | 1505*2445*2100 |

| EYH-2000A | 2000 | 1200 | 600 | 5.2 | 2600 | 1635*2445*2120 |

| EYH-3000A | 3000 | 1800 | 900 | 7.0 | 3500 | 1905*2755*2420 |

| EYH-4000A | 4000 | 2400 | 1200 | 9.5 | 4100 | 2035*3205*2550 |

| EYH-6000A | 6000 | 3600 | 1800 | 13 | 6100 | 2265*3805*2960 |

| EYH-8000A | 8000 | 4800 | 2400 | 13 | 7900 | 2555*4305*3390 |

| EYH-10000A | 10000 | 6000 | 3000 | 18.5 | 10000 | 2665*4355*3420 |

| EYH-12000A | 12000 | 7200 | 3600 | 18.5 | 13000 | 2465*4985*3760 |

| EYH-15000A | 15000 | 9000 | 4500 | 22 | 15000 | 3035*5055*4150 |

| EYH-20000A | 20000 | 12000 | 6000 | 30 | 18000 | 3295*5155*4500 |

About Us:

From dryer, mixer to granulator, from unit

machine to production line, we have them all. Hywell Machinery is

a professional manufacturer of industrial drying machine, mixing machine

and granulating machine. Our flagship products include the hot air dryer,

vibration fluid bed dryer, belt dryer, vacuum dryer, one dimensional mixer, two

dimensional mixer, three dimensional mixer, and high speed granulator and so

on. These high-performance machines have extensive applications within

industries such as food, medicine and chemical. Sustained development and

a strong emphasis on research and technology have bolstered our quality

standards. we seek to achieve the highest level of customer satisfaction

through professionally developed drying ,mixing and granulating solutions.

Hywell Machinery constant faith is providing perfect products to customer,

excellenting service to customer !

Quality control

In order to ensure quality of product, we focus on user 's requirements and control improvement and enhancement quality of products .The quality assurance mainly focus on the processes of ensuring production readiness inspection, control of raw materials and components, process control, critical parts, important parts of quality control, assembly quality control, process control testing, measurement equipment control. Pay close attention to the implementation of the quality assurance work, strictly to three inspection system of self-checking, mutual inspection, special inspection. The key point of Quality assurance is focuses on critical parts, important parts of quality control, the quality standards required by ISO9000 quality control procurement documents in order to clarify its status and acceptance of quality standards for company's re-inspections ; For critical parts and important that the key processes of identification and corresponding technical documentation, control by "the implementation of key quality control process", and complete, accurate and complete original records. Difficulties in quality assurance is a special process control, quality assurance is mainly painting, has developed a special process (painting) process documents, take the appropriate technical measures, to quality assurance.

In the production process, we pay close attention to quality control of each process. Every component, every process was strictly controlled. Enhanced the quality inspection process, the establishment of the necessary quality control point, the process by a full-time staff and quality inspector for inspection and supervision. Improved testing procedures and operating instruction.

OUR SERVICES

Pre-sale service

We Invite customers to visit our company and

communicate on technical requirements face to face.

Sale service

Responsible for debugging the equipment

according to customers' requirements of various technical data. Our engineers

will train our customers about equipment features and operation key points to

make sure the equipment running in the best condition.

After-sale service

We provide installation, debugging,

maintenance, training and other services (Optional); Provide relevant technical

data, equipment, software and related GMP certification materials;Set up

after-sales service hotline, and arrange personnel to visit customers every

year to know more customer needs,like customer operation problems in the

process of production equipment.

Quality promise

Our company promises strictly operate the

ISO9001 quality system certification standards and pharmaceutical equipment GMP

audit requirements,promise we provide new equipment. Advanced technology,good

quality.Equipment operation safe reliable, affordable, easy to maintain.

Equipment warranty period is one year,all the

parts for the equipment choose well-known brand.

During the warranty when equipment have problem

in quality like equipment failure and damage, our company offer free

maintenance or replacement.

Changzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier