1 / 3

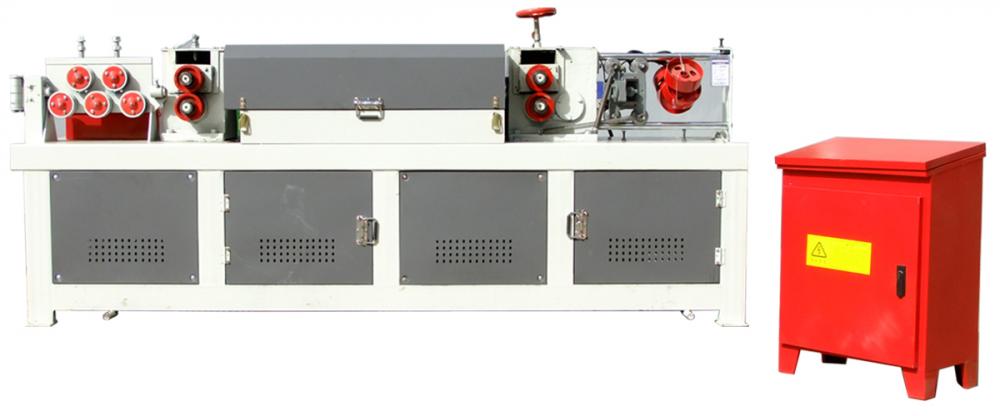

Hydraulic CNC automatic straightening machine

| Brand Name : | Borong |

|---|---|

| Applied material : | Metal |

Xingtai, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Product description

Precautions when using

1. Before using the machine, the power should be turned on first, and the test operation can be used only after there is no abnormality.

2. Before use, you should understand the relationship between the direction of the swivel and the direction of the steel bar. The bar should be inserted counterclockwise in the direction of the swivel rotation (the same direction as the positive bolt).

3. When using, insert one end of the reinforcing bar into the straightening machine to the outlet end, then adjust the two bolts in the rotating body. The straightened steel bars are automatically spit out during the rotation of the straightener.

4. Note: It is forbidden to insert steel bars before the machine is started.

Product description

The fully automatic CNC hydraulic bar straightening cutting machine is a machine used for straightening and rebaring of steel bars on construction sites. It is suitable for straightening and cutting of ordinary disc snails on construction sites, steel processing shops, etc. Equipped with a computer numerical control panel, easy to operate and agree to get started. This shop has a variety of models, please contact customer service for details.

Maintenance and lubrication

1. Clean all parts of dust, debris and rust in time to prevent oil from rust.

2. Always check whether the oil level in the machine cavity is above the oil mark.

3. If the machine stops working for a long time, the motor needs to be removed.

4. After the first refueling, the new oil should be replaced after one month. After 6 months, the bearing should be added with calcium grease (butter).

Technical parameter

|

Straightening diameter range |

Φ4-Φ14mm |

|

Straightening speed |

55m/min |

|

Cut length error |

±5mm |

|

Traction motor |

11KW |

|

Cut off the motor |

5.5KW |

|

Cut length |

30cm-9900cm |

|

Total Weight |

900kg |

|

Dimensions |

2800×700×1100mm |

As a professional machinery manufacturer, we do have different kinds of construction machinery. Thread Rolling Machine For Sale, contact me if you need it. We will offer you a reasonable Roll Thread Machine Price and best Thread Rolling Services. Besides this Z28-80, we do have Z28-200 Type Thread Rolling Machine, they are both High Speed Thread Rolling Machine. Also we have Steel Straightening Machine, Rebar Bending Hoop Machine, Hydraulic Concrete Converying Transport Pump, and so on. The most important, it can be customized according to various needs.

Xingtai, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier