1 / 2

Hot rolling Forged grinding balls for cement 90mm

| Model No. : | ZWG-69 |

|---|---|

| HARDNESS : | 58-65 |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Product description

- Hot rolling Forged grinding balls for cement 90mm and 80mm

-

Produce all kinds of hot-rolled ball-grinding ball according to the forged (rolling) steel ball ferrous metallurgy industry standard (YB/T 091-2005). The diameter of steel ball is Φ25-Φ125mm. The blank of rolling ball-grinding ball is the hot-rolled round steel bar with various chemical components, and the diameter is equal to the nominal diameter of steel ball. The production technology process of hot-rolled steel ball is as follows:1. After the inspection, the round steel bar is cut into the steel ball blank according to the specified lengths.2. Before the rolling, the steel ball blank is heated to the appropriate temperature in continuous heating furnace.3. The billet under the red and hot state is sent into the ball rolling mill, and moves forward between the two rollers with special hole patterns, and it is made into the steel ball. Each ball rolling mill can produce 60-360 steel balls per minute.4. The rolled steel ball under the red and hot state is immediately sent into the online heat treatment equipment designed by our factory for quenching - tempering heat treatment, so that the steel balls can get the high and even hardness.5. The qualified products are sent to the finished goods warehouse, packaged and delivered to the customers.

- FEATURE OF OUR FORGED GRINDING BALLS

Jinan Zhongwei forged grinding balls are manufactured from selected high carbon alloy steel bars and manually forged by air hammer.

Jinan Zhongwei forged grinding balls ,followed by in-line water heat treatment ,and uniform quenching,tailored to even hardness throughout .

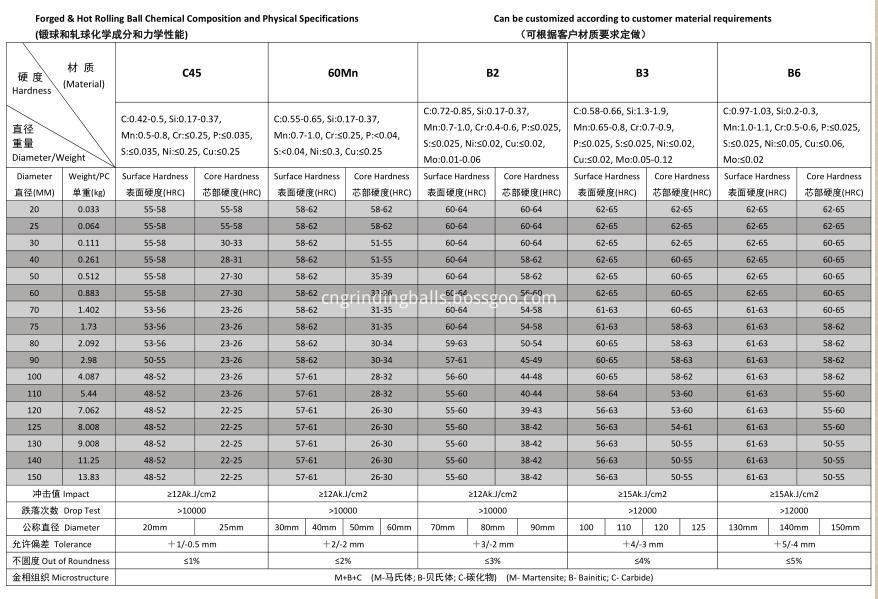

Jinan Zhongwei forged grinding balls avaliable in size 20mm to 150mm with various specifications,meet an equally wide range of grinding and milling need.

- TYPES OF OUR FORGED GRINDING BALLS

- QUALITY CONTROL OF OUR FORGED GRINDING BALLS

1). We set up a professional technical team.

Every working procedure we always follow the details of the accused, by providing more wear-resisting of grinding media to help customers to reduce the cost of grinding.

- QUALITY GUARANTEE OF OUR FORGED GRINDING BALLS

Our forged grinding balls come with the following guarantees:

1. Breakage guarantee:

.Over 5 %replacement of the complete mill charge

2. Proven Wear rates of:

.Forged Grinding balls tested: 50mm and 60 mm forged steel balls

- PACKING AND DELIVERY OF OUR FORGED GRINDING BALLS

Seaworthy standard packaging: Container bags or steel drums or with wooden or non-wooden pallets (At buyer's option)

Delivery: By Sea transportation, in container or bulk vessel.

Port of loading: Qingdao Port,China

Jinan, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Send your inquiry to this supplier