Video

1 / 4

Hollow Anchor Bar R25N Self-drilling Anchor Bolt

| Model No. : | R25N |

|---|---|

| Brand Name : | GZ STEEL |

| standard : | Jis,Gb,Din,Bs,Astm,Aisi |

Jinan, Shandong, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Product Introduction

Hollow anchor bar means a rod that transfers the structures or geotechnical load to a stable rock formations, anchor bolt consists of bar, drill bit, coupling, plate, grouting stopper and nut. Widely used as an efficient anchoring means, in tunnel pre-support, slope, coast, mine, water conservancy projects, building foundation, roadbed reinforcement and geological diseases treatment such as landslip, crack, sink age. It’s irreplaceable in narrow construction environment. Hollow anchor bar is made of seamless tube with high strength.

Features of Hollow Grouting Anchor Bar :

Hollow design, implement the grouting tube function, avoid the mortar loss when the traditional grouting tube pulled out.Grouting full, and can achieve the pressure grouting to improve project quality.

Center is good, mortar can wrap the bolt body together, so that it can avoid corrosion to achibe along term supporting purposes.

Easy installation, without onsite processing of threads. It can be easily installed an plate, nut.

Selt-Drilling Anchor Bar Description :

It may bodies drilling, grouting and anchoring as a whole.

It has a wide specifications. Diameter: 25-130mm.

Quality and easy construction, high efficiency.

Used invious surrounding rocks.

Product Specification

Anchor Bar

|

|

R25N |

R32N |

R32S |

R38N |

R51L |

R51N |

T76N |

T76S |

|

Outside diameter (mm) |

25 |

32 |

32 |

38 |

51 |

51 |

76 |

76 |

|

Internal diameter (mm) |

14 |

19 |

16 |

19 |

36 |

33 |

52 |

45 |

|

Ultimate load capacity (KN) |

200 |

280 |

360 |

500 |

550 |

800 |

1600 |

1900 |

|

Yield load capacity (KN) |

150 |

230 |

280 |

400 |

450 |

630 |

1200 |

1500 |

|

Tensile strength, Rp0.2 (N/mm2) |

800 |

800 |

800 |

800 |

800 |

800 |

800 |

800 |

|

Yield strength, Rp0.2 (N/mm2) |

650 |

650 |

650 |

650 |

650 |

650 |

650 |

650 |

|

Weight (Kg/m) |

2.3 |

3.2 |

3.6 |

5.5 |

6.5 |

8.0 |

16.0 |

19.7 |

|

Thread type (left-hand) |

ISO 10208 |

ISO 1720 |

MAI T76 Standard |

|||||

|

Steel grade |

En10083-1 (Alloy structure steel) |

|||||||

|

Compared to carbon steel, alloy structure steel has high anti-corrosion capacity and high mechanical. |

||||||||

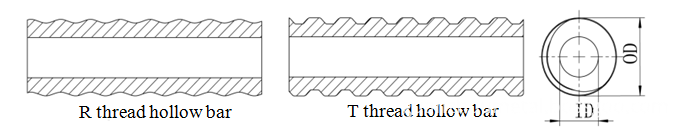

Thread size: R25, R32, R38, R51, T76.

Thread standard: ISO10208, ISO1720 etc.

Anchor Plate

|

|

R25N |

R32N |

R32S |

R38N |

R51L |

R51N |

T76N |

T76S |

|

Dimention (mm) |

150*150 |

200*200 |

200*200 |

200*200 |

200*200 |

250*250 |

250*250 |

250*250 |

|

Thickness (mm) |

8 |

10 |

12 |

12 |

20 |

40 |

40 |

40 |

|

Hole diameter (mm) |

30 |

35 |

35 |

41 |

60 |

60 |

80 |

80 |

|

Weight (KG/PC) |

1.4 |

3 |

3.7 |

3.6 |

8.8 |

18.5 |

18 |

18 |

|

Cold deformed with geometry |

||||||||

Anchor Coupling

|

|

R25N |

R32N |

R32S |

R38N |

R51L |

R51N |

T76N |

T76S |

|

Outside diameter (mm) |

35 |

42 |

42 |

52 |

63 |

63 |

95 |

95 |

|

Length (mm) |

120 |

145 |

160or190 |

180 |

180 |

200 |

200 |

200 |

|

Weight |

0.45 |

0.7 |

0.75 |

1.4 |

1.7 |

1.9 |

6.4 |

6.4 |

|

Machined steel coupling middle stop |

||||||||

The hollow bar is continuously threaded, it can be cut and coupled anwhere along its length.

The coupling enables direct end-to-end energy transmission between each bar, reducing losses and ensuring maximum percussive engergy at the drill bit.

Drill Bit

|

|

R25N |

R32N |

R32S |

R38N |

R51L |

R51N |

T76N |

T76S |

|

Diameter (mm) |

41,51 |

51,76,90 |

90,100,110,115,130 |

130,150,160,180,200 |

||||

|

Hardened cross bit (EX) |

Hardened cross bit for loose to medium dense condition with small boulders. |

|||||||

|

Tungsten cross bit (EXX) |

TC cross bit for soft to medium rock for mations |

|||||||

|

Hardened button bit (ES) |

Hardened buuton bit for unconsolidated rock with boulders. |

|||||||

|

Tungsten carbon button bit (ESS) |

Button bit with TC inserts for medium rock for formations. |

|||||||

|

Hardened arch bit (EC) |

Hardened drill bit with optimized geometry for uncon solid dated soil with small boulders. |

|||||||

|

Tungsten carbon arch bit (ECC) |

TC drill bit with optimized geometry for soft to medium rock formations. |

|||||||

|

Hardened drop center bit (EY) |

Hardened cross bit for loose to medium dense ground conditions |

|||||||

|

TC drop center bit (EY) |

TC drill bit for soft to medium rock formations. |

|||||||

|

Casting clay bit (EW) |

Casting clay bit with optimized geometry for very soft to soft caly. |

|||||||

|

Machined steel bit or Casring steel bit |

||||||||

The sacrificial drill bit is an important part of the self drilling anchoring system.

Choose suitable bits according to different soil type.

Anchor Nut

|

|

R25N |

R32N |

R32S |

R38N |

R51L |

R51N |

T76N |

T76S |

|

Key size (mm) |

41 |

46 |

46 |

50 |

75 |

75 |

100 |

100 |

|

Length (mm) |

135 |

45 |

45 |

55 |

70 |

70 |

80 |

80 |

|

Weight (kg/pc) |

0.25 |

0.35 |

0.35 |

0.5 |

1.55 |

1.55 |

3.6 |

3.6 |

|

Machined steel nut or casting steel nut |

||||||||

The hexagonal and spherical nuts are made from high precision steel (40Cr,HRC 20-25) to meet the stringent demands on anchor specifications and the daily uses of reinforcement work.

All nuts exceed the ultimate strength of the rod.

T-Thread Anchor Rod Technial Data

|

Bar Type |

Outside Diameter (mm) |

Inside Diameter (mm) |

Cross section (mm2) |

Ultimate Load KN |

Yield Point KN |

Weight (kg/m) |

Thread Left/ Right Hand |

|

30/11 |

30 |

11 |

446 |

320 |

260 |

3.3 |

Lift or right |

|

30/14 |

30 |

14 |

395 |

260 |

220 |

2.9 |

Lift or right |

|

30/16 |

30 |

16 |

382 |

220 |

180 |

2.7 |

Lift or right |

|

40/16 |

40 |

16 |

879 |

660 |

525 |

7.0 |

Lift or right |

|

40/20 |

40 |

20 |

726 |

539 |

430 |

5.6 |

Lift or right |

|

52/26 |

52 |

26 |

1337 |

929 |

730 |

10.0 |

Lift or right |

|

73/53 |

73 |

53 |

1160 |

1630 |

970 |

12.3 |

Lift or right |

|

73/56 |

73 |

56 |

1094 |

1414 |

785 |

11.1 |

Lift or right |

|

73/45 |

73 |

45 |

2265 |

1630 |

1180 |

17.8 |

Lift or right |

T thread anchor bar surface with a trapezoidal thread, this design of connection is much stronger and reliable when compared with rope thread, we supply full sizes from T30 to T103.

Thread size: T30, T40, T52, T73, T103, T127, T130.

Thread standard: ISO10208, ISO1720 etc.

Product And Factory Display

Product Test

Technology Process

The Self Drilling Anchor system is comprised of a hollow threaded anchor bar with a sacrificial drill bit that performs drilling,anchoring and grouting in a single operation. Self drilling anchor system is mainly used in slope stabilization, tunneling pre-support, foundations with micro piles etc projects.

1. Connect the alloy drill and anchor rod one end, on the other end, connect the drill sleeve and shank adapter, then connect the drilling rig or hand-held drill. Then start drilling, fill the cooling water while drilling.( If you want to lengthen the anchor rod, can connect the coupling, and then drilling)

2. Take down the drill, put the stop-grouting plug into the rod, and insert it to the hole, then ready to grout. Special circumstances like surrounding rock grouting tension is over or surrounding rock is too broken, can use anchor agent to seal the hole.

3. Connect quick grouting coupling and anchor rod end, connect other end of grouting machine.

4. Start grouting, when grouting full and reach design value then power off. Grouting pressure according to the design parameters and grouting machine performance determine, Cement/sand reference values is 1:0 ~ 1:1, water/cement reference value is 0.45:1 ~ 0.5:1.

5. Install anchor plate and nuts, and tighten nuts.

Application:

During the constructions of underground works, it is very common to encounter soft rock, fractured zone and large deformation due to high ground stress. In the case of serious collapsing, hollow grouted anchor bar extra-long anchor is needed instead of ordinary one.

Packaging And Transportation

The packaging is packaged in tarpaulins and wooden boxes to ensure that it will not rust and corrode in the process of encountering water.

FAQ

Q1:Can you send samples?

A:Of course, we can provide customers with free samples and express shipping service to all over of the world.

Q2:What product information do I need to provide?

A:Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q3:It's my first time to import steel products, can you help me with it?

A:Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:What ports of shipment are there?

A:Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

Q5:What is your terms of payment?

A:Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment or based on BL copy or LC at sight.

Q6:Do you provide custom made Products service?

A: Yes,if you have your own design , we can produce according to your specification and drawing.

Q7:What are the certifications for your products?

A:We have ISO 9001, MTC, third parties' inspections are all available such SGS, BV ect.

Q8:How long does your delivery time take?

A:In general, our delivery time is within 7-15 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q9: How many countries you already exported to?

A:We have exported to America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, India, Kenya, Ghana,somalia and other African countries.Our export experience is rich, we familiar with different market demands, can help customers avoid a lot of trouble.

Q10:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q11:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q12:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion and various climate changes during ocean transportation.

Video

Jinan, Shandong, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier