1 / 5

High Strength Metallurgical Grade Silicon Carbide

| Model No. : | F24SiC |

|---|---|

| Brand Name : | Yi Feng Rui Da |

| Refractoriness (℃) : | 1770< Refractoriness< 2000 |

Shizuishan, Ningxia, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Trade Company

- Platform Certification

Product description

1.Product Introduction

Deoxidizer of silicon carbide (sic) is a new strong compound deoxidizer, replacing the traditional silicon powder toner deoxy physical and chemical properties are morestable deoxy effect, so that the deoxidation time compared to the original process, saving energy, steel-making to improve efficiency, improve quality, reduce the consumption of rawand auxiliary materials, reduceenvironmental pollution, improveworking conditions, improve theoverall economic efficiency of the furnace are of great value. In addition, high-grade refractory bricks, outlet, electronic board, refractory class of widely used.

2.Product Application

Silicon carbide used for 3-12 inch monocrystalline silicon, polycrystalline silicon, potassium arsenide, quartz crystal wire cutting. Solar photovoltaic industry, semiconductor industry, piezoelectric crystal industry, engineering materials.Silicon carbide for semiconductor, lightning rod, circuit components, high temperature applications, UV detectors, structural materials, astronomy, disc brakes, clutch, diesel particulate filter, filament pyrometer, ceramic film, cutting tools, heating elements , Nuclear fuel, jewelry, steel, protective gear, catalyst support and other fields.

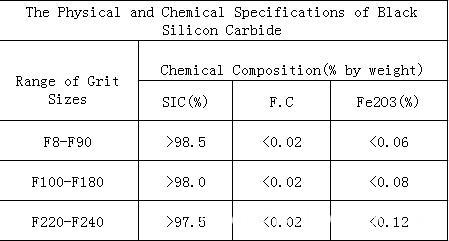

3.Product Index

4.Product process

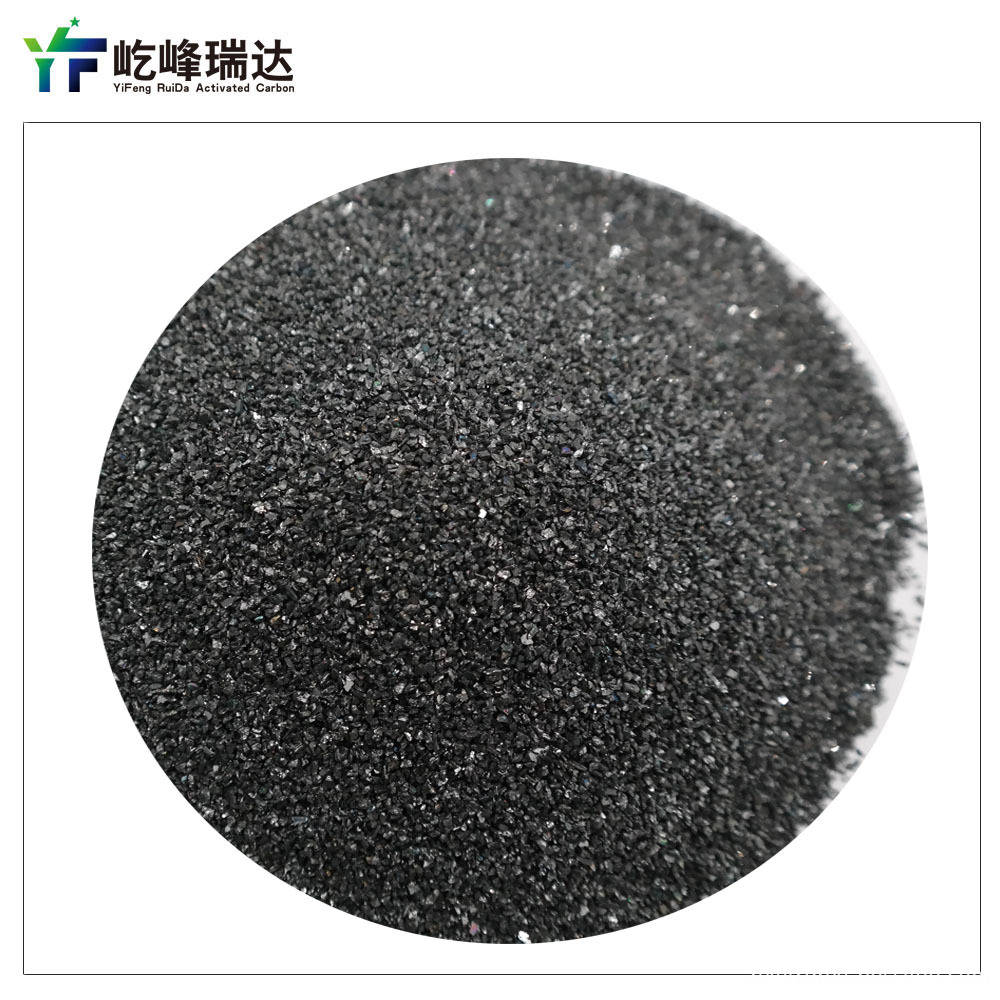

The anthracite quartz sand and other mineral raw materials processed into pieces, and then broken, the initial crushing, after fine broken, plastic, magnetic separation, screening after the silicon carbide products have been obtained, the final package can be shipped

5.Packing And Transportion

Woven bag, lined with plastic film bags, each 25kg can also be packaged according to customer demand.

Transportation and handling: During the transportation process, the silicon carbide shall not be dragged with hook, should prevent mixing with hard materials. It should belight unloading to reduce packaging crushing.

Storage: The silicon carbide should be stored in a cool and dry place, to prevent rupture of bags, to prevent moisture and other substances to affect the product. Storage should away from sources of pollution.

Shizuishan, Ningxia, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Trade Company

- Platform Certification

Send your inquiry to this supplier