1 / 2

High quality injection plastic mold

Get Latest Price

Send Inquiry

| Brand Name : | dongye |

|---|---|

| place of origin : | China |

More

3yrs

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Suzhou Dongye Precision Molding Co.,Ltd.

You might also like

Product description

Product description:

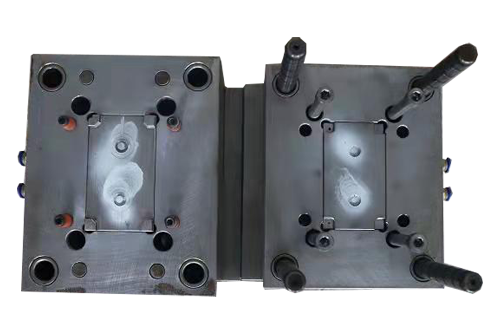

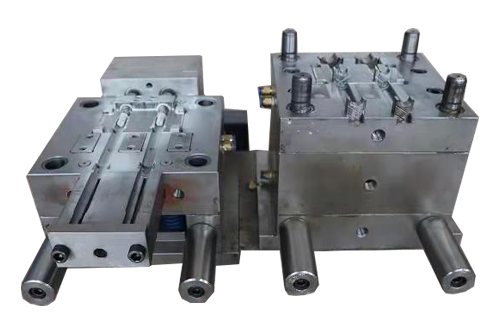

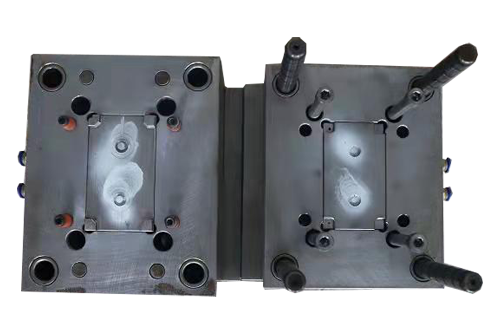

High quality injection plastic mold

Provide customized parts rapid proofing to mass production of one-stop processing services, business scope covers customized parts, sheet metal processing, processing,CNC and other customized parts, labor package materials package post-processing. Professional production of various standard and non-standard metal parts, covering electrical hardware, electronic hardware, robot accessories, medical machinery hardware, instrumentation hardware, aviation, navigation, fishing hardware, automotive hardware, communication hardware and other fields, thousands of varieties for customers to choose. Choose us, is your clear choice, we focus on precision parts and design, sound production, sales as one. A large number of CNC lathe testing equipment, professional manufacturing plants, high processing accuracy.

Our products cover: LED light optical lenses, Light housing and cover, Automobile plastic products, Electronic equipment shell, Electronic precision connectors, Medical instruments, Disinfection devices, Household application plastic cases, other structure parts, silicone molding products and so on. Tolerance could meet +/- 0.02 mm.

With 15 years experience, under our strict managing and quality controlling, we are fighting to get full customers’ satisfaction. Homoiothermal molding workshop, 100% income and output checking, periodical workers training, fast service response and responsible after-sale service, we believe we can be your long term partner.

We have a very professional design team that can provide customers with efficient design support. After the customer confirms the design plan, fast and high-quality 3D printing or CNC machining prototypes and processing models can make your ideas come true.

After model and prototype are confirmed, it will be mold design and manufacturing, product injection and production assembly. We have strict production management and an excellent manufacturing team. Our experienced engineers and salesmen will ensure that your industrial engineering to tooling engineering, project management by experienced engineers and efficient engineering discussion is available at anytime.We have excellent mold making lead time, some molds 40 days, some molds even 20 days, up to your parts.

High quality injection plastic mold

Provide customized parts rapid proofing to mass production of one-stop processing services, business scope covers customized parts, sheet metal processing, processing,CNC and other customized parts, labor package materials package post-processing. Professional production of various standard and non-standard metal parts, covering electrical hardware, electronic hardware, robot accessories, medical machinery hardware, instrumentation hardware, aviation, navigation, fishing hardware, automotive hardware, communication hardware and other fields, thousands of varieties for customers to choose. Choose us, is your clear choice, we focus on precision parts and design, sound production, sales as one. A large number of CNC lathe testing equipment, professional manufacturing plants, high processing accuracy.

Our company also sells Product Development,Rapid Prototype,3D Print,Plastic Injection MoldingPlastic Mould Maker, welcome to consult.

Injection Tooling & Mold Design

Project Design and Mold production service:

Our mould service includes: New project design, Product development, 3D print and rapid cnc machining prototype, Assist in testing, Plastic mould design and manufacturing, Injection molding OEM and assembly service. We are a professional plastic injection mold maker in mould OEM industry.Our products cover: LED light optical lenses, Light housing and cover, Automobile plastic products, Electronic equipment shell, Electronic precision connectors, Medical instruments, Disinfection devices, Household application plastic cases, other structure parts, silicone molding products and so on. Tolerance could meet +/- 0.02 mm.

With 15 years experience, under our strict managing and quality controlling, we are fighting to get full customers’ satisfaction. Homoiothermal molding workshop, 100% income and output checking, periodical workers training, fast service response and responsible after-sale service, we believe we can be your long term partner.

We have a very professional design team that can provide customers with efficient design support. After the customer confirms the design plan, fast and high-quality 3D printing or CNC machining prototypes and processing models can make your ideas come true.

After model and prototype are confirmed, it will be mold design and manufacturing, product injection and production assembly. We have strict production management and an excellent manufacturing team. Our experienced engineers and salesmen will ensure that your industrial engineering to tooling engineering, project management by experienced engineers and efficient engineering discussion is available at anytime.We have excellent mold making lead time, some molds 40 days, some molds even 20 days, up to your parts.

3yrs

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier

Send Inquiry