1 / 5

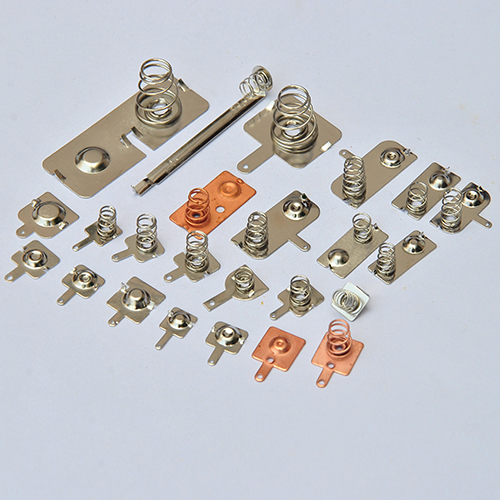

High precision hardware stamping parts

| Model No. : | SYM-0505 |

|---|---|

| Delivery Time : | 7-15 Days For Sample,15-20 Days For Large Goods |

Dongguan, Guangdong, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- SGS Certification

Product description

Metal stamping parts including cold stamping/hot satmping.Cold stamping is at room temperature, the use of punching die in the press for sheet metal or pressure on the thermal material, make its produce plastic deformation or separation to obtain the required shape and size of the parts of a pressure processing method.

Stamping tools metal parts company

Product Name :stamping part

Working Process :stamping, deep stamping, bending, punching, threading,welding, tapping, riveting

Material :Stainless steel, carbon steel,copper, brass, and bronze (according to customer's requirements)

Surface Treatment :hot galvanized, polishing, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, imitation gold-plated, powder coating, etc.

Packing :Inner-Plastic Bag; Outer -Standard Carton Box.

Usage :All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more

Quality Control:Conducted by ISO/TS16949:2002 and ISO14001:2004 system.

Equipments:CNC stamping/punching machine, CNC bending machine, CNC cutting machine, 5-250T punching machines, welding machine, polish machine

Applications auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc

Thickness 0.5mm~12mm, or other special available

File Format Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

Product Image:

FAQ:

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: TT/ Paypal/ Western Union .

Small amount 100% TT payment . large amount T/T accept 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF,

Q4. How about your delivery time?

A: Generally, it will take 7-10 days sample time. 15 to 25 days after receiving your advance payment. The specific delivery time depends on the items quantity and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from

Q9: Your are a trade company or producer?

Our company is factory ,have our self machines,Design, research and development, production.

Q10.How many years in this industry ?

More than 16 years.

Production Flow:

Certification

Dongguan, Guangdong, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- SGS Certification

Send your inquiry to this supplier