Video

1 / 3

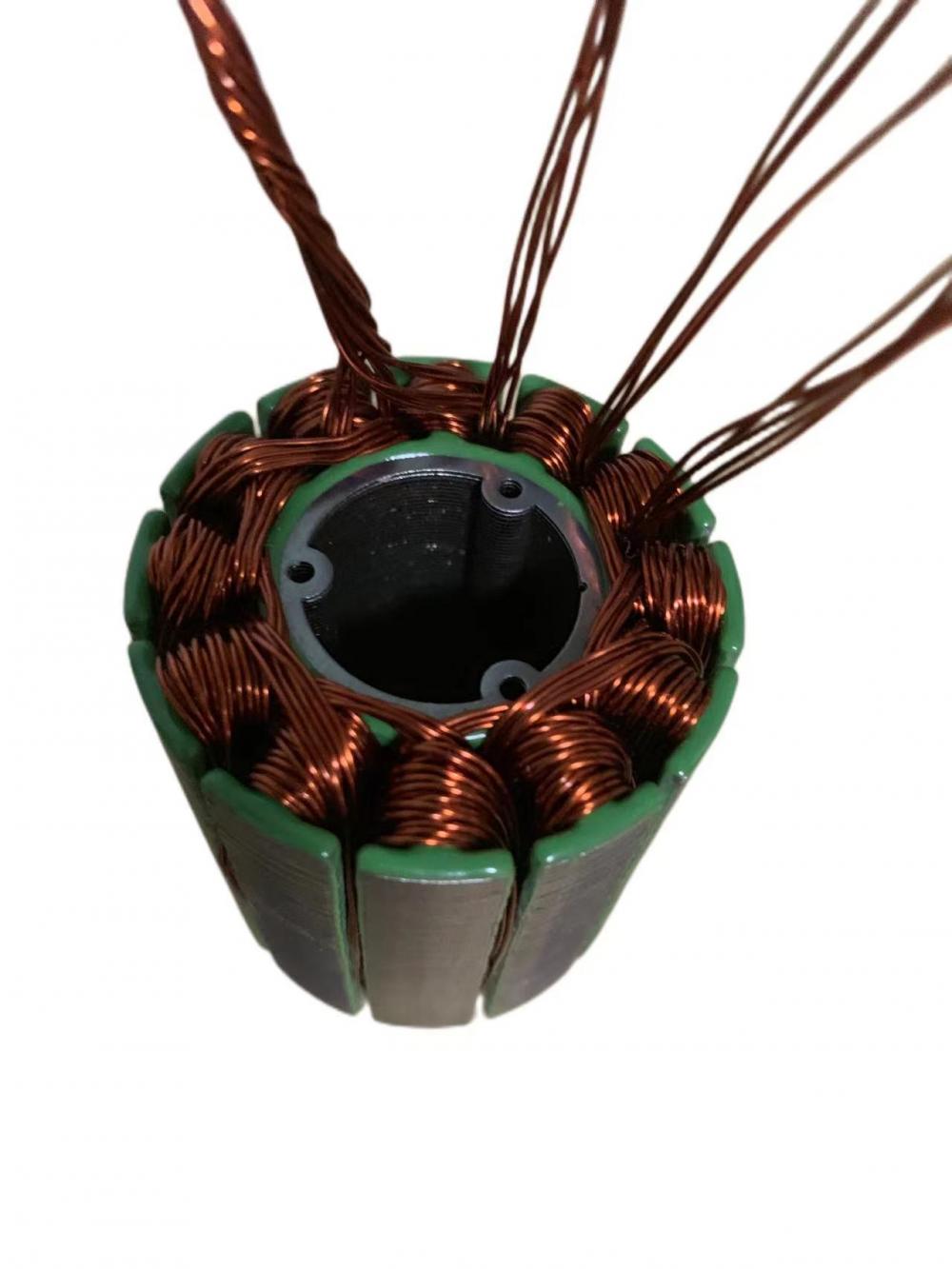

High efficiency electric motor stator lamination

$20.00

≥100 Others

$19.00

≥1000 Others

$16.00

≥5000 Others

Types:

- Laminated Cores

- Stator

Options:

- Stator core

- Stator lamination

- Motor stator

| Model No. : | ATS4609 |

|---|---|

| Brand Name : | ATS |

| warranty period : | 3months-1year |

Product description

1. Increased efficiency: Multi-strand winding allows for a larger number of turns per coil, resulting in higher efficiency. This is because the increased number of turns reduces the resistance and increases the magnetic field strength, leading to improved motor performance.

2. Reduced losses: Multi-strand winding helps to reduce copper losses in the motor. By using multiple thinner strands of wire instead of a single thicker wire, the skin effect is minimized. This effect causes higher resistance at higher frequencies, but with multi-strand winding, the current is distributed more evenly across the strands, reducing the overall resistance and losses.

3. Improved cooling: The use of multiple strands in the stator winding increases the surface area available for cooling. This allows for better heat dissipation, preventing overheating and extending the motor's lifespan.

4. Higher power density: Multi-strand winding enables higher power density in electric motors. By increasing the number of turns and reducing losses, more power can be outputted from a motor of the same size.

5. Enhanced reliability: The redundancy provided by using multiple strands in the winding increases the reliability of the motor. If one strand were to fail, the motor could still operate with reduced performance, allowing for continued functionality until maintenance or repair is possible.

Overall, the use of multi-strand winding in the stator of an electric motor offers improved efficiency, reduced losses, better cooling, higher power density, and enhanced reliability.

OD

ID

Material

Thickness

Powder coating thickness

Withstand Voltage

Temperature rating

Wire diameter

Application

46.9mm

21.46mm

50WW600

0.5mm

0.6mm

800-1400V/AC/0.5mA

B, F, H

0.53mm

DC Brushless motor

Video

Send your inquiry to this supplier