Video

1 / 3

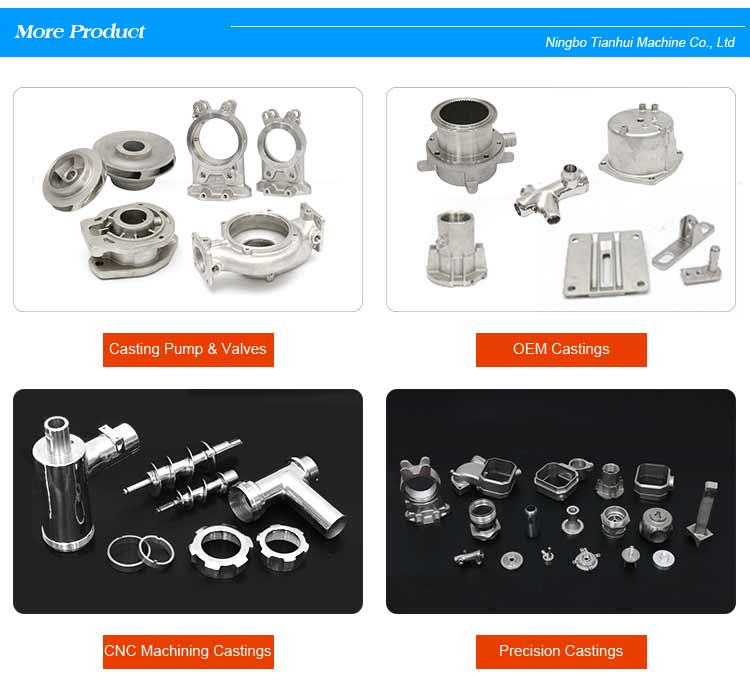

gravity casting part aluminum permanent casting part

$8.62

≥500 Piece/Pieces

$6.75

≥2000 Piece/Pieces

Options:

- Certificate: ISO9001:2015

| Model No. : | aluminum gravity casting parts |

|---|---|

| Brand Name : | OEM/Tianhui |

| place of origin : | China |

Ningbo, Zhejiang, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Product description

gravity casting part aluminum permanent casting part

| Technical | investment casting and CNC Machining |

| Material | stainless steel , carbon steel , alloy steel |

| Material Grade | GB, ASTM , AISI , DIN , BS, JIS, NF |

| Weight | 10g~50kg |

| Accuracy | casting tolerance CT6-CT7, machining tolerance ISO2768-mk |

| Surface Roughness | up to Ra0.7~Ra3.2 |

| Applied software | ProE (.igs , .stp) , Auto CAD , PDF, Jpeg, Jpg, Png |

| Production capacity | more than 1500MT per year |

| Heat Treatment |

anneal,quenching,normalizing,carburizing, polishing, plating, painting |

| Machining Equipment |

CNC center , CNC machines, turning machines, drilling machines , milling machines, grinding machines |

| Measuring Tool |

CMM , Projector, pneumatic micrometer, magnetic powder inspection, vernier caliper, depth caliper, micrometer, pin gauge, thread gauge , height gauge |

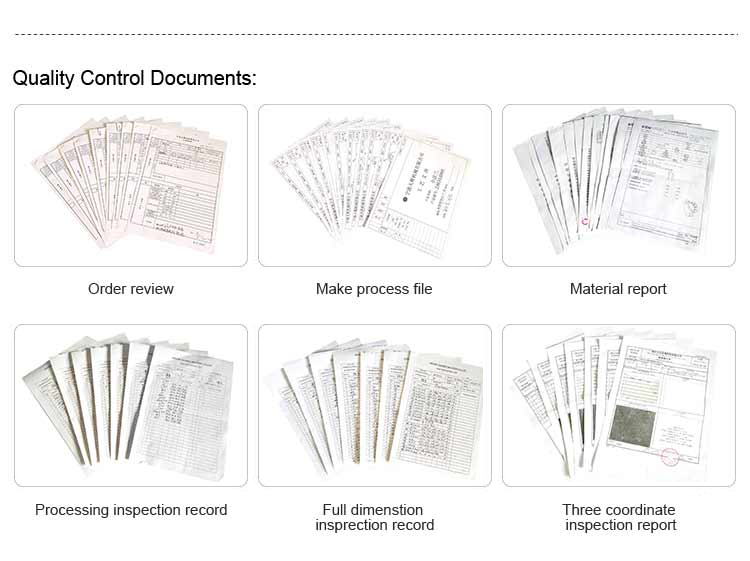

| QC system | 100% inspection before shipment |

| MOQ | 500kg |

| Lead Time | sample fast , lot production depends on customers' request |

| Certification | ISO9001:2015 |

| Payment Terms | T/T , L/C, D/P , D/A |

| Shipment Terms | FOB , CFR, CIF |

Investment Casting/Lost Wax Casting:

|

1.Mold and Pattern Making |

A mold is built to customer-provided specifications. Cold wax is then injected into the mold to creat a wax pattern/prototype that will hold precise dimensional requirements in the final casting |

|

2. Pattern Assembly |

The wax patterns are assembled onto the sprue. |

|

3. Dipping and Coating |

Successive layers of ceramic and stucco are applied to the sprue assembly to form a hard shell. |

|

4. De-waxing and Firing |

The molds are flash-fired to remove the wax and sprue materials and then heated to 1800° and placed on a sand bed, ready for pouring |

|

5. Casting |

Molten metal, up to 3000°, is poured into the hollow mold and then cooled. |

|

6. Knockout |

The ceramic shell is broken off, and the individual castings are cut away. |

|

7. Finishing |

Excess metal is removed, surfaces are finished, and castings are heat treated. |

|

8. Testing and Inspection |

Castings undergo thorough testing and inspection to ensure that they meet dimensional tolerances and specifications. |

|

9. Packing and Shipping |

Castings are securely packaged for shipping to the customer. |

gravity casting part aluminum permanent casting part

Investment casting also called silica sol casting, lost wax casting, precision casting. Material is stainless steel, carbon steel, alloy steel. Standard of GB, ASTM, AISI, DIN, BS, JIS, NF. Our main material grade is 1.4408, CF8, CF8M, 4140, SS304, SS316, 40Cr, 42CrMo, etc.

Advantages of Investment Casting:

1. Large application. Not limit to size, thickness and structure, all can produce by casting. Flexible mode of production. Our casting parts mainly use for Pump & Valve industry, agricultural machinery, construction machinery, food machinery, marine hardware, auto parts, etc.

2. A wide range of materials can be used. Extensive use of used metals and renewable resources.

3. Castings have certain dimensional accuracy, small processing margins, the processing time and the metal material are saved.

4. Low cost, good comprehensive economic performance. Low energy, material consumption and cost.

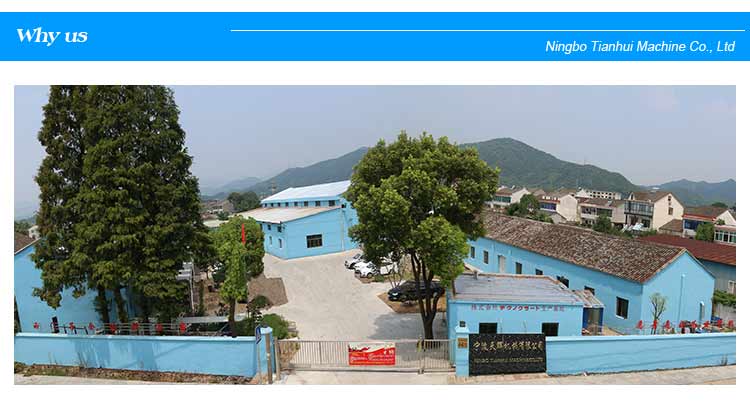

Ningbo Tianhui Machine Co., Ltd.

CNC machining process

Our company is a professional OEM / ODM CNC machining factory engaged in the development, production, sale and service. With 15sets cnc centers and 23 cncs , can precision cnc machine custom parts. We are SIEMENS global supplier for hundred kinds of metal parts for high voltage circuit breakers. Our goods application of pump and valve industry, auto parts, food machinery parts, agricultural machinery parts, construction machinery parts, marine hardware.

Our main material is stainless steel, carbon steel, alloy steel, aluminum, iron. We supply CNC machining service of bar or tube material, casting blanks, forging blanks. We manage heat treatment, plating, galvanic coating, anodizing, powder coating with our cooperation factories. Provide one stop service since drawing, mold design and development to goods manufacture, heat treatment, surface treatment, inspection and packing. We are located in Ningbo, with convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has bought series of advance manufacturing and inspection equipment, including CNC centers, CMM, Image Measuring Instrument. In addition, we have obtained ISO 9001:2015 certification, also comply with 5S management system. In precondition of quality guarantee , we insist in process optimization, reduction of production cost , savings concession to customer. With consistent high praise from customers.

Q: Why choose China Ningbo Tianhui Machine Co.,Ltd? Any advantages?

A: The answer is Yes. There are 5 advantages.

(1) MUTUAL BENEFIT: Our offer will be reasonable, our price will be cheaper in the same quality.

(2) CUSTOMIZE: We can make the product as your request, Shape and Quality can meet your request.

(3) OEM: (1)Laser Print your Logo. (2)Design your packing box.

(4) MIX ORDER: We accept mix order, different model and small quantity order.

(5) AFTER SERVICE: Can reback the off-test product or ask back the payment when get the off-test goods and judged off-test by the third testing party .

Q: Can I order one piece for sample to test the quality?

A: Yes, We recommend to check the sample before order. Please order the sample in our retail store.

Q: May I have your catalogue and price list for trial order in MOQ quantity?

A: We mainly produce the product follow the customer drawings . And all our products were shown on alibaba, please have a detailed looking and choose the interested models in our site.

Video

Ningbo, Zhejiang, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier