1 / 3

Granulating Mill For Biomass Pellet

| Model No. : | SZLH580 |

|---|---|

| Brand Name : | Kingoro |

| Voltage : | 380V |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Product description

Product Description of Pellet Granulating Mill For Biomass:

Pellet Granulating Mill For Biomass is designed for mass production of particles designed mechanized production equipment, which can be less than 15% moisture of various types of biomass raw materials into high-density pellets, pressed particles can be used as pellet fuel can also be used as Pellet feed. Widely used in animal husbandry, small and medium-sized breeding factory, feed mill and brewing, sugar, paper, medicine, tobacco and other industries waste organic granulation, is (bio) organic fertilizer production enterprises preferred the ideal equipment.

Granulating Pellet Mill For Biomass is a new biomass fuel production machinery by using crushed sawdust and bran from eucalyptus,pine,birch,poplar,fruit and agricultural straw,bamboo.

Compared with the old machine,sawdust pellet machine absorbed the essence of horizontal ring die and flat die pellet machine,solved the insufficient pressure,die crack problems of horizontal ring die pellet machine,and overcame the small capacity,high failure rate of flat die pellet machine.

Transmission system

1. Grass pellet machine adopts the hardened tooth surface to reduce the tooth surface, the tooth surface is widened, the modulus is increased, the meshing degree is large, and the load bearing capacity is enhanced, which is 3-5 times of the life of the conventional reducer.

2. The gear of the gearbox adopts the grinding process of the German NILES gear grinding machine. The transmission is stable, low noise , the service life is long, and it can withstand high power and heavy load.

3. The spindle is shortened and the torque is large.

Applicable Material:

Applicable to: rice husk, sunflower seed shell, peanut shell and other melon shell; branches, trunks, bark and other wood scrap; all kinds of crop straw, rubber, cement, gray Slag and other chemical raw materials, etc.

Specification of Grass Pellet Machine:

Model

SZLH470

SZLH560

SZLH560G

SZLH580

SZLH600

SZLH660

SZLH760

SZLH850

Power (kw)

Capacity (t/h)

Weight (T)

55

0.7-1

2.6

90

1.2-1.5

5.6

132

1.8-2

6.5

90

1-1.5

5.5

110

1.3-1.8

8.6

132

1.5-2

8.8

160

1.5-2.5

9.6

220

2.5-3.5

13

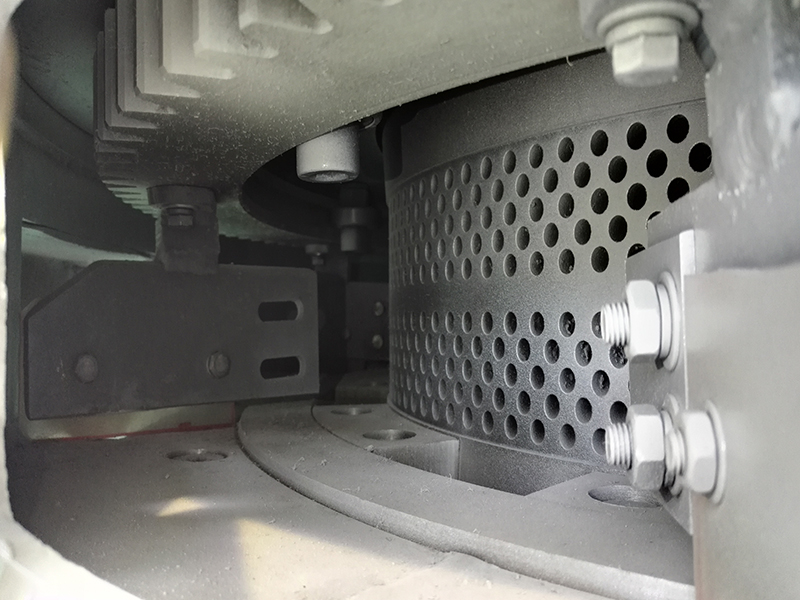

Grass Pellet Machine Details:

FAQ:

1.We need to know the following information to give a quote and solution

1)What is your raw materials? (to confirm mould pressure ratio of machines )

2) What is the moisture content of your raw material?

3)How many output capacity do you want per hour / month/ year?

Note: If the moisture is high, you need a dryer, becuase the suitable moisture content to enter pellet machine is 10-15%.

And please provide us above detailed information, then we would design the most suitable production line with reasonble offers.

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Send your inquiry to this supplier