1 / 5

good quality high speed stud used roll forming machines

| Model No. : | ZM |

|---|---|

| Brand Name : | Zhouming |

| Certification : | Other |

Shijiazhuang, Hebei, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

good quality high speed stud used roll forming machines

We are chinese company with our own factory. Our factory has advanced machines, many-year experience, trained workers. And our aim is providing you the best service. Curragated roof sheet roll forming machine is one of our main products. It can be used to be manufactoring Corrugated Steel Roofing Tile. Apart of it, we can provide Glazed Steel Sheet, Trapezoidal Rib Steel Roof Tile, Rock Wool Sandwich Panels and so on. If you are interested in our products, you can contact me.

Specifications:

Roll Forming Machine Feeding material: zinc-coated steel coil

Cold Roll Forming Machine Thickness of the plate:0.3-0.6mm

Feeding Material width:1000/1200/1250mm

Rolling material: 45# steel with hard chrome plated

Rolling station:12-20 rows of rollers

Productivity:8-15m/min

Voltage:380V/50HZ/3Phase

Cutting blade: Cr12 with heat treatment

Cutting system: Hydraulic cutting system after forming

Control cabinet: PLC and frequency changer in it

Warranty:12 months limited warranty

Delivery: 30 days after receipt of advance payment

Package: Plastic packing and nude in the container

Payment Term: T/T, L/C, Trade assurance

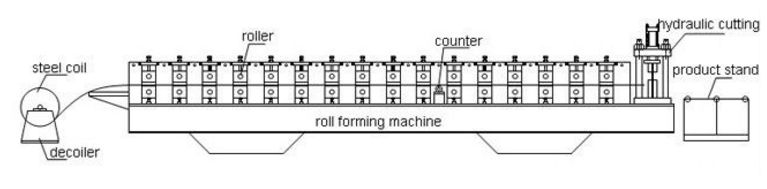

Produce process flow

Components

1.Manual un-coiler:to load steel coils

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

It adopts Taida PLC to control(can make as your requirement). The target piece length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one.

5. Cutting Mechanism

It adopts hydraulic drive and automatic location to decide the dimention and cut the target products. Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine. Stop to cut , Post cut

6. Recieving table:Main framework adopts welded steel and supported roller, and used for transmit and collect the finished products.

Packing&shippment

1.Packing:the main parts will be packed with plastic film then fixed to container by iron wire

2.Shippin:shipped in 30days after receiving the full deposit

Shijiazhuang, Hebei, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier