Video

1 / 2

Glazed Ceramic Tube Body for Vacuum Power Feedthroughs

Options:

- Metalized Ceramic Tube Body

- Industrial ceramic parts

- Mo/Mn metallization + Nickel plating

- High brazing strength, high gas tightness

- Used in ceramic to metal seal technology

| Model No. : | Customized |

|---|---|

| Brand Name : | Jinghui Ceramics |

| place of origin : | China |

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

Glazed Ceramic Tube Body for Vacuum Power Feedthroughs

Metalized ceramic tube body is one of critical part in vacuum power feedthroughs, which offer unmatched dielectrical strength and outstanding mechanical strength. In the meantime, the ceramic tube could make the leakage rate low to 1*10-11 Pa.m3/s after brazing between ceramic and metal components.

They are commonly made from high purity alumina ceramic, such as 96% alumina, 99% alumina. They can be shaped by dry pressed, Isostatic pressed. In order to increase the electrical insulation strength and keep the surface of ceramic body away from foreign contaminations, sometimes, the ceramic tubes needs to be with glass glaze finish.

We can proceed with small part-size to large part-size, the min. diameter can be 1mm, the largest diameter is up to 500mm. In order to meet customers' different needs, we offer a selection of types of metallization, the typical ones as below:

1. Ceramic tube + Molybdenum (Mo/Mn) metallization 2. Ceramic tube + Mo/Mn metallization + Nickle(Ni) plating

3. Ceramic tube + Silver(Ag) plating 4. Ceramic tube + Tungsten (W) metallization + Gold(Au) plating

Technical Key Parameters of metalized ceramic insulator

Leak Rate

≤1x10-11Pa.m3/s

Metal Layer Tensile Strength

≥150Mpa

Volume Resistivity

Insulation Strength

≥18kV/mm (D•C)

Dielectric Constant

9~10(1MHz, 20°C)

Cosmetic Quality:1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No contamination

≥108Ω•cm

Coefficient of Thermal Expansion

(5 ~ 8.0) × 10-6 /°C

The typical application of metallized ceramic insulators

Widely used in vacuum interrupters, Electron tubes,Gas discharge tube, Vacuum capacitor,Vacuum thyristors, Surge arresters, Thyristor housings, Diode housings,Power grid tubes,Traveling wave tubes,Insulator rings and cylinder,X-ray tubes and so on.

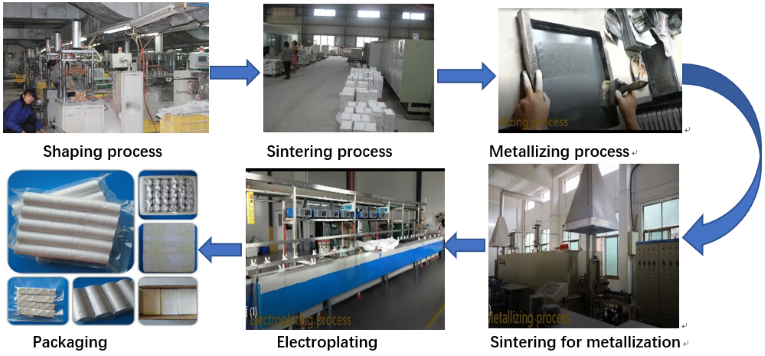

Main manufacturing flow chat of metalized ceramic parts

We have a complete comprehensive of production equipment for metallized ceramics from shaping to electroplating.It helps us to make the dimensional consistency very well. Also, helping us to offer a competitive price.

Established in 2008, Jinghui Industry Ltd. View More

Video

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier