1 / 6

GH4090 High-temperature Alloys

Get Latest Price

Send Inquiry

| Model No. : | GH4090 |

|---|---|

| Brand Name : | JIADE |

| place of origin : | China |

1yrs

Xian, Shaanxi, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Shaanxi Jiade Import And Export Co., Ltd

You might also like

Product description

GH4090 High-temperature Alloys

High-temperature Alloys can also be called Superalloy Material, today JIADE Steel will bring you together with this GH4090 High-temperature Alloys products.

GH90 is Ni-Cr-Co based precipitation hardening deformation Superalloy Material, the use of temperature up to 920 ℃ ℃ Steel alloy in 815 ℃ ~ 870 ℃ has a high tensile strength and creep resistance, good oxidation and corrosion resistance, in the role of cold and hot repeatedly alternating with high fatigue strength. Because the alloy has good processing and welding properties, it has many applications in aerospace, such as making aero-turbine engine turbine disks, blades, high-temperature fasteners, clamps, seals and elastic components.

Our company can now provide Special Steel Material, which can be customized according to the delivery requirements, such as hot rolled bars, cold drawn bars, cold rolled plates, strips and cold drawn wires, etc. GH4090 high temperature alloy has been used to make aero-engine high-temperature spring originals, high-temperature fasteners, combustion chamber clamps and stop pins and other parts.

GH90 alloy steel has good oxidation resistance and corrosion resistance below 1040℃, but is prone to intergranular oxidation above 1040℃.

GH4090 Heat Treatment System

GH4090 Heat Treatment System

GH4090 cold drawn bar: 1080℃±10℃,air cooling or water cooling +750℃±10℃,4h,air cooling.

Diameter or smaller cross-section size / mm ≤ 3 >3 ~ 6 >6 ~ 12.5 >12.5 ~ 25

GH4090 sheet and strip (soft state): softening treatment 1100 ~ 1150 ℃, 1 ~ 10min, appropriate medium cooling +750 ℃ ± 10 ℃, 4h, air cooling.

GH4090 sheet and strip (hard state): 700 ~ 725 ℃, 4h, air cooling.

GH4090 spring cold drawn wire: 600 ℃ ± 10 ℃, 16h, air cooling or 650 ℃ ± 10 ℃, 4h, air cooling.

GH4090 cold-drawn and solution-treated spring wire: 1080 ° C ± 10 ° C, 8h, air-cooled + 700 ~ 750 ° C, 4h, air-cooled.

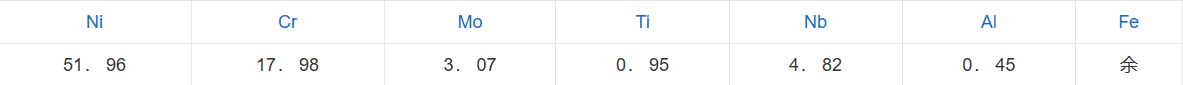

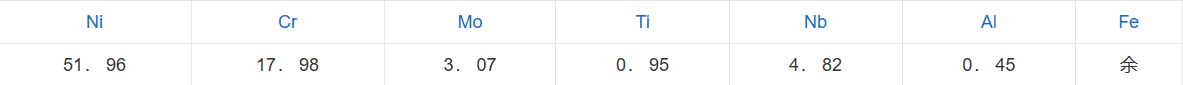

GH4090 high temperature alloy chemical composition

GH4090 Process Properties and Requirements

GH4090 forming properties The alloy is prone to internal cracking during forging, and does not allow heavy hammer blows or low-temperature chamfering. Ingot loading temperature not higher than 700 ℃, final heating temperatu

re 1150 ℃ ± 10 ℃, open forging temperature not lower than 1060 ℃, final forging temperature not lower than 950 ℃. Rolling heating temperature 1160 ℃, final rolling temperature of not less than 950 ℃. Cold-drawn material in the final intermediate annealing should be 8% to 12% cold deformation.

GH4090 welding performance Alloy in solid solution state can be inert gas shielded tungsten arc welding and flash butt welding.

GH4090 parts heat treatment process The heat treatment process of the parts is carried out according to the heat treatment system of the corresponding material technical standards.

GH4090 cutting and grinding performance GH4090 in the solid solution state has good machinability, after aging treatment, the use of hardened tools according to the specified amount of feed slow processing.

1yrs

Xian, Shaanxi, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier

Send Inquiry