Video

1 / 2

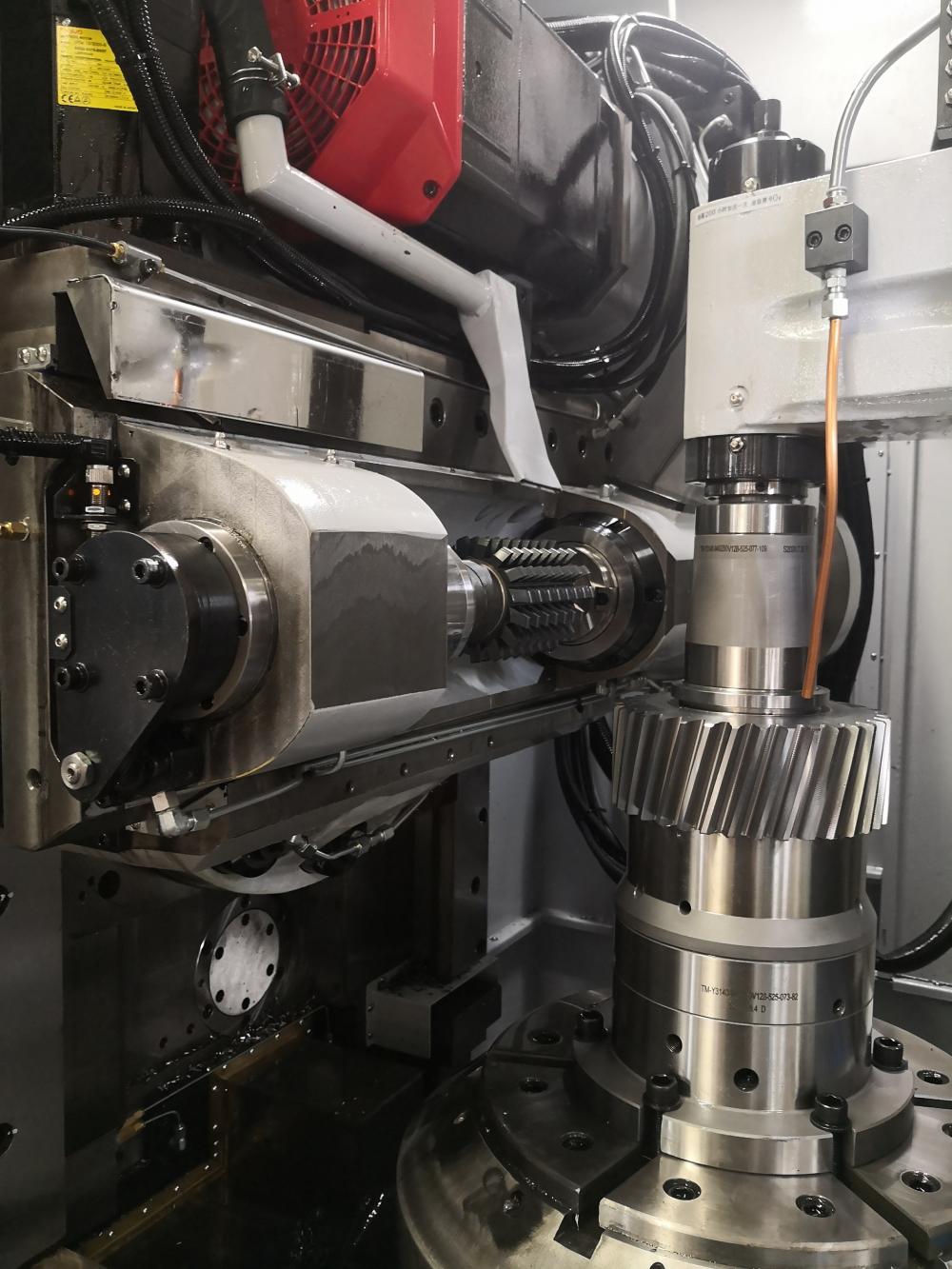

gear cutting lathe machine gear making for Agricultural

| Model No. : | Y3150CNC6 |

|---|---|

| Brand Name : | TOMAN |

| place of origin : | China |

Product description

Agricultural machinery refers to all kinds of machinery used in the process of crop planting and animal husbandry production, as well as the primary processing and treatment of agricultural and animal products. Agricultural machinery includes agricultural power machinery, farmland construction machinery, soil tillage machinery, planting and fertilization machinery, plant protection machinery, farmland drainage and irrigation machinery, crop harvesting machinery, agricultural products processing machinery, animal husbandry machinery and agricultural transportation machinery.

TOMAN offers manufacturing solutions to customers, for the broadest spectrum of gear manufacturing applications. The gear cutting machines for gear hobbing, gear shaping–as well as gear and profile shaving, gear automatic production line–are further developed by highly qualified staff and adapted to the requirements of the customer in the process.

TOMAN has been manufacturing highly productive gear hobbing machines since 2006. The large selection of machine types fulfils specific customer requirements–from the automotive industry to wind turbine manufacturers,construction machines,high-speed train etc.

Y3150 CNC6

a versatile hobbing machine suited for large sized gears

A powerful 6 axis full CNC hobbing machine

An extremely rigid hobbing machine

FANUC numerical control system and servo drive, system reliability, simple operation

Wet Cutting Hobbing Machine

Max. Workpiece Diameter: Φ500 mm

Max. Module: 10/12

gear cutting lathe machine gear making for Agricultural :

1)The full CNC system has 6-axis and 4 linkage, use generating method, realized indexing and differential compensation movement with CNC electronic gear box function, it can finish the cylindrical spur gear, helical gear and small taper tooth, drum gear, spline, worm gear, sprocket and so on tooth process .

Main Technology Parameter

|

CNC hobbing machine |

Unit |

Y3150 |

|

|

|

Wet hobbing |

|

Max. workpiece diameter |

mm |

Φ500 |

|

Maximum module |

mm |

10/12 |

|

Worktable surface diameter |

mm |

Φ450 |

|

Hob Maximum Assemble DiameterX Length |

mm |

Φ170/Φ 240x300 |

|

Horizontal distance between hob center and worktable center |

mm |

45-375 |

|

Maximum hob axial movement amount |

mm |

180/200 |

|

Hob head slide travel (Z axis movement amount) |

mm |

200-600 |

|

Maximum swiveling angle of the hob head |

Deg |

±45° |

|

Hob spindle motor power |

KW |

15 |

|

Maximum hob spindle rotate speed(B axis) |

rpm |

500/750 |

|

Maximum worktable rotate speed(C axis) |

rpm |

75 |

|

Radial feed speed (X axis)(stepless) |

mm/min |

1-2000 |

|

Radial maximum rapid move speed(X axis) |

mm/min |

5000 |

|

Axial feed speed(Z axis)(stepless) |

mm/min |

1-2000 |

|

Axial maximum rapid moving speed(Z axis) |

mm/min |

6000 |

|

Tangential feed speed(Y axis) (stepless) |

mm/min |

1-1000 |

|

Radial maximum rapid travel speed(Y axis) |

mm/min |

2500 |

Standard Configuration

|

Hob arbor assembly ( Φ40) |

hydraulic system |

|

Hob arbor automatic clamping device |

NC controller system |

|

Workpiece automatic clamping device |

NC data memory card |

|

Spindle positioning |

Operational software |

|

Fully-enclosed safeguards |

Residual-current circuit breaker |

|

Woking light |

Hands action button |

|

Three colour lights indicate machine status |

RS232C connector |

|

Workpieces counter |

Air conditioner for electric cabinet |

|

Main spindle ampere meter |

Chip conveyor |

|

Chip cart |

Automatic lubrication system |

|

Cutting oil tank |

Mist collector |

|

Cold spray gun |

The sizing block for machine adjustment |

Optional Configuration

|

Automatic loading/unloading material device |

Workpiece clamping |

|

Automatic material storage |

Workpiece rough locator device |

|

Deburring device |

Automatic tooth align device |

|

Independent hob adjustment device |

Oil cooling device |

|

Hob arbor assembly:(metric system:Φ22, Φ27, Φ32, Φ50, Φ60),(Inch system: Φ26.988, Φ31.75, Φ38.1, Φ50.8) |

|

Video

Send your inquiry to this supplier