1 / 1

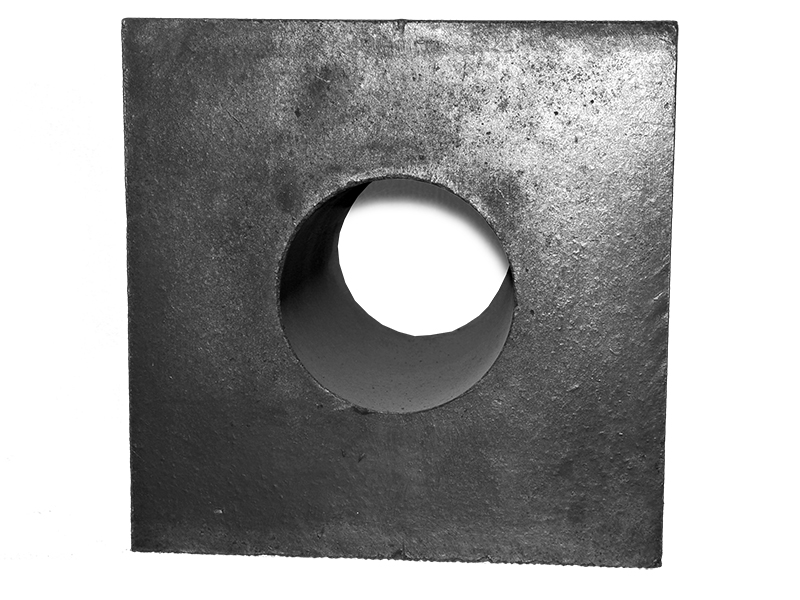

Fused Alumina Magnesia Carbon Bricks

| Brand Name : | GuoXin |

|---|

Product description

Fused Alumina Magnesia Carbon Bricks

Refractories in steel ladle are subjected to severe operating conditions like high temperature (1670-1700°C) tapping of liquid steel from BOF, thermal shock, abrasion with molten metal due to stirring during gas purging, localized heating in slag zone due to arcing, corrosion with slag, thermo mechanical stress etc. Hence, use of superior quality refractory material with evenly distributed impurities is essential to get an end product of very high corrosion and spalling resistance and high thermo-mechanical properties. Easier application technique is also required for higher lining life with less down time. Various qualities of magnesia carbon refractories are used in different zones of steel ladles & BOF. Magnesia carbon refractories are essentially constitute of two highly refractory components i.e. magnesia and graphite.

Magnesia carbon bricks

| Brand | MgO (%)≥ | C (%)≥ | Apparent porosity A.P(%)≤ | Bulk density B.D(g/cm3)≥ | Compressive strength at room temperature C.C.S MPa≥ |

| MT-10B | 77 | 10 | 4 | 3 | 45 |

| MT-12B | 75 | 12 | 4 | 2.95 | 40 |

| MT-10A | 80 | 10 | 3.5 | 3.05 | 45 |

| MT-12A | 77 | 12 | 3.5 | 3 | 40 |

| MT-14A | 75 | 14 | 3 | 2.95 | 40 |

| MT-16A | 72 | 16 | 3 | 2.95 | 35 |

Alumina magnesia carbon bricks

| Brand | MgO (%)≥ | Al2O3 (%)≥ | C (%)≥ | Apparent porosity A.P(%)≤ | Bulk density B.D(g/cm3)≥ | Compressive strength at room temperature C.C.S MPa≥ |

| AMT-60 | 16 | 57 | 12 | 4 | 2.92 | 50 |

| AMT-65 | 17 | 62 | 10 | 4 | 2.95 | 50 |

| Type | Magnesia Aluminum Carbon Brick | Magnesia calcium carbon brick | |||||

| Index grade | MAC60 | MAC70 | MAC74 | MGT5 | MGT2 | MGT13 | |

| MgO(%)≥ | 55 | 68 | 71 | 70 | 75 | 70 | |

| Al2O3(%)≥ | 23 | 8 | 6 | - | - | - | |

| C(%)≥ | 8 | 10 | 10 | 5 | 2 | 8 | |

| CaO(%)≥ | - | - | - | - | - | - | |

| B.D(g/cm3) ≥ | 3 | 2.9 | 3 | 2.9 | 2.85 | 3 | |

| Apparent porosity AP(%)≤ | 6 | 5 | 5 | 6 | 7 | 5 | |

| Compressive strength at room temperature CCS(Mpa)≥ | 30 | 35 | 40 | 30 | 30 | 35 | |

Main applications:

Magnesia-carbon bricks have a wide range of uses, and can be used in key parts of thermal equipment such as steel-making converters, electric arc furnaces, ladles, and out-of-furnace refining furnaces. The aluminum-magnesium-carbon bricks made of high-quality bauxite clinker, fused corundum, and fused magnesia have low thermal conductivity, good thermal insulation, and appropriate residual expansion.

They are used for ladle, lower wall, bottom and free Good materials for the department. The performance of magnesia-aluminum-carbon bricks is between that of magnesia-carbon bricks and aluminum-magnesia-carbon bricks. Magnesia-calcium carbon bricks are made of high-quality magnesia, dolomite sand and synthetic magnesia dolomite sand as raw materials, and anhydrous resin as a binder. Good slag resistance, more stable under high temperature vacuum, and can clean molten steel. It is suitable for VOD furnace, AOD furnace and LF furnace of external scouring device.

Dashiqiao Guoxin Refractory Material Co., Ltd. is located in Dashiqiao, Liaoning Province, which is the capital of magnesium in China. The company enjoys superior geographical position, with Beijing-Shenyang Expressway, Shenzhen-Dalian Expressway

Send your inquiry to this supplier