Video

1 / 1

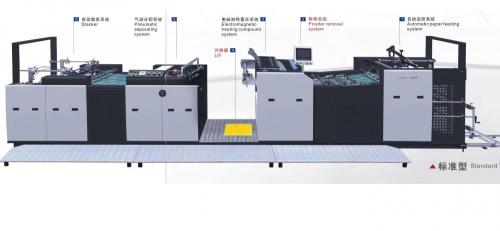

Fully Automatic High-speed Pre-coating Film Laminating Machine

$1.00

≥1 Set/Sets

| Model No. : | ZXFMD-1050 |

|---|---|

| Brand Name : | Inovo |

| Applicable industry : | Other |

Chuzhou, Anhui, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Features

1.Any combination of powerful multi-functional configuration can solve various problems of laminating process!

(1)Double-sided laminating (both sides are laminated at the same time)

(2)Dust removal (remove surface dust and surface preheating, enhance surface brightness/mattity/and fit)

(3)Double pressing (Enhanced surface compaction and fastness twice)

(4)UV dryer(Lamination has strong fastness, especially to solve the problem of embossing, embossing and embossing of the large solid base film)

(5)Chain knife (cutting of tailless film and high toughness film such as PET and aluminum foil film)

(6)Hot knife (high speed) (Slitting of high toughness films such as tailless film and PET, aluminum foil film)

(7)Coding (online coding)

(8)Corona device (to solve the problem of low corona value, silk screen, paste box, hot stamping, etc.)

(9)Static elimination device (excessive static electricity, large paper adhesion)

(10)Embossing system: various embossing reflects the aesthetics of surface decoration!

2. Pre-stacker mechanism to realize non-stop paper feeding and receiving

3.Adopt high-speed offset press feeder (12000 sheets/hour) to ensure fast and stable operation

4.High degree of intelligence, the whole machine is controlled by PLC and man-machine, and each part is frequency-converted and servo-linked to ensure speed synchronization and easy for one person to operate.

5.Electromagnetic heating system: the temperature rises and falls quickly, the heating roller adopts an electromagnetic heating system and a built-in oil heating system to make sure the temperature is uniform.

6.Driven by the synchronous belt, the equipment is more stable and the accuracy is better.

7.The equipment adopts servo edging, which has higher accuracy and more stability

8.The main pressure shaft is combined with electric pressure

9.Automatic lifting film, reducing labor intensity and safety

10.The main roller adopts double chain, no jump, high running stability, it is not easy to stretch after a long time, which affects the accuracy!

Applications

The YFMD-A series is a high-speed pre-coating model launched by our company, which is suitable for posters, books, information albums, posters, color boxes, color box packaging, handbags, etc.

Technical parameters

|

Item |

Unit |

ZXFMD-850 |

ZXFMD-1050 |

ZXFMD-1200 |

ZXFMDS-1200 |

|

Max laminating paper |

mm |

850*1000mm |

1050*1000mm |

1200*1000mm |

1200*1450mm |

|

Min laminating paper |

mm |

270*2700mm |

290*290mm |

300*300mm |

340*340mm |

|

Paper weight paper Cardboard use heavy feeder more thickness |

g/㎡ |

100-500g/㎡ |

100-500g/㎡ |

100-500g/㎡ |

100-500g/㎡ |

|

Overlap error |

mm |

+_2mm |

+_2mm |

+_2mm |

+_2mm |

|

Laminating speed (Depending on the material, color and color block size of the printed product, the machine runs at different speeds) |

m/min |

oneside:0~80m/min Double side:0~60m/min(optional) |

oneside:0~80m/min Double side:0~60m/min(optional) |

oneside:0~80m/min Double side:0~60m/min(optional) |

oneside:0~80m/min Double side:0~60m/min(optional) |

|

Power(Different configuration, different power) |

kw |

28kw |

30kw |

30kw |

30kw |

|

Working power |

KW/H |

18KW |

20KW |

20KW |

20KW |

|

Paper feed height |

mm |

1150 |

1150 |

1150 |

1150 |

|

Paper stack height(including tray) |

mm |

1050 |

1050 |

1050 |

1050 |

|

Overall Dimensions |

mm |

10500*1800*2000mm |

10500*1800*2000mm |

10500*2000*2000mm |

11500*2200*2000mm |

|

Total weight |

kg |

10500kg |

11500kg |

12500kg |

13500kg |

Machine structure

|

Main components |

||||

|

|

||||

|

Series |

Accessory Name |

Brand |

Note |

|

|

1 |

Pressure rubber roller |

Jingyang |

JingYang |

Taiwan |

|

2 |

feeder |

|

RUN |

Offset feeder |

|

3 |

Bearing |

Harbin |

|

|

|

4 |

Vacuum pump |

Shanghai Mengxu |

|

|

|

5 |

chain |

Hangzhou |

|

|

|

6 |

Pneumatic clutch |

Taiwan |

|

Taiwan |

|

7 |

Servo motor |

Inovance |

|

Shenzhen |

|

8 |

Server Driver |

Inovance |

|

Shenzhen |

|

9 |

Oil hydraulic pump |

Zhejiang |

|

|

|

10 |

electromagnetic heating |

|

Shenzhen |

|

|

11 |

Touch screen |

Weiluntong |

|

|

|

12 |

Pneumatic parts |

Airtac |

|

Taiwan |

|

13 |

Button |

OMRON |

OMRON |

Japan |

|

14 |

Contactor.relay |

Schneider |

|

France |

|

15 |

Sensor |

Panasonic |

|

Japan |

|

16 |

Proximity switch |

Panasonic |

|

Japan |

|

17 |

Temperature Controller |

OMRON |

OMRON |

Japan |

|

18 |

Photoelectric switch |

Panasonic |

|

Japan |

|

19 |

PLC |

Inovance |

|

Shenzhen |

|

20 |

Frequency converter |

Inovance |

|

Shenzhen |

Spare parts

|

1 |

Name |

Warranty |

Note |

|

2 |

Rubber roller |

6 months |

Need to be ground (except for cracking) |

|

3 |

Scraper blade |

3 months |

|

|

4 |

suction nozzle |

None |

|

|

5 |

UV lamp |

1000H |

|

|

6 |

Brush wheel |

None |

|

|

7 |

Pneumatic parts |

6 months |

|

Anhui Innovo Bochen Machinery Manufacturing Co., Ltd. is a global business enterprise engaged in the manufacture, marketing, research and development of machinery. Our firm also provides import and export operations and technical training. We ar

Video

Chuzhou, Anhui, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier