Video

1 / 3

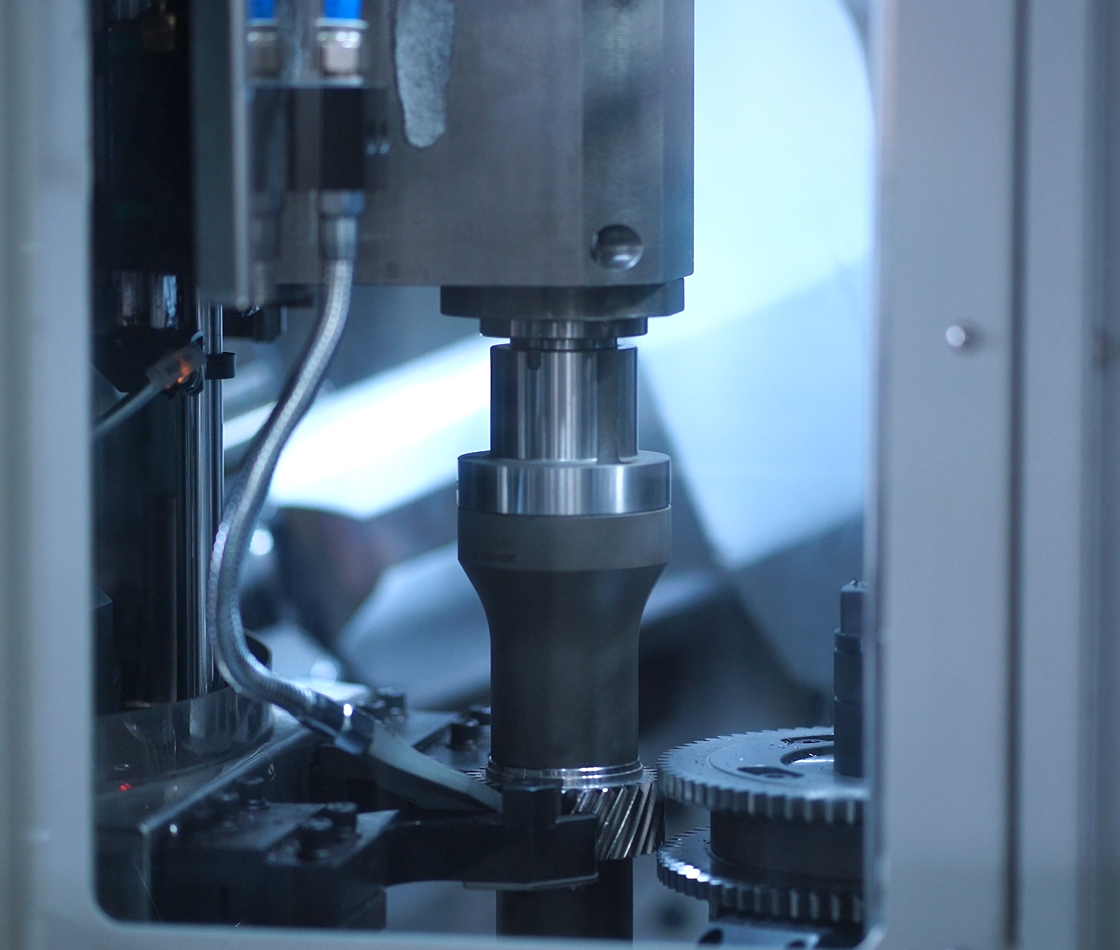

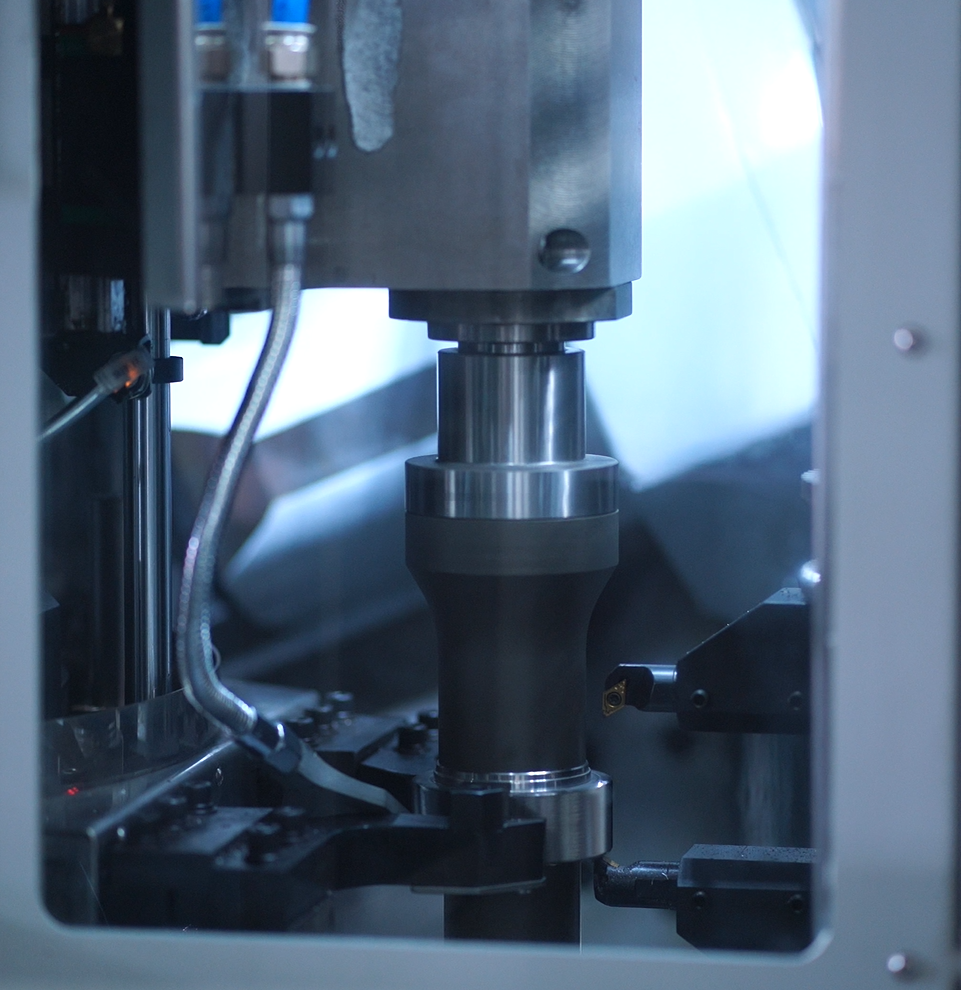

Fully automated gear cutting and manufacturing gear4 ktm

| Model No. : | Y3115CNC7 |

|---|---|

| Brand Name : | TOMAN |

| place of origin : | China |

Product description

We Provide High Speed High Accuracy Gear Machinery and other Workpieces Solutions with Premium Quality Service to Global Users.

Machines What We Supply: Gear Hobbing Machines, Spiral Bevel Gear Machines,Gear Shaving Machine,Gear Grinding Machines, Gear hobbers,CNC Machining Centers etc.

This equipment is suitable for hobbing and chamfering small and medium modulus gears in the industries of Gearbox for Passenger Vehicles and Construction Machinery etc.

Y3115 CNC11

11 Axis-CNC Hobbing Machine

high efficiency intelligent Gear Hobbing Machine

CNC Chamfer Rolling and Deburring Unit with Two-Cut Hobbing Process for Burr-Free Flanks

Realize the processing of rough rolling, extruding edge, deburring and fine rolling in one clamping

FANUC numerical control system and servo drive, system reliability, simple operation

High-Speed Hobbing - Dry or Wet

Highly Efficient Gear Shaping Machine

Type

Function

Processing Range

Max. Modulus

(mm )

Max. Dia.

(mm)

Min. Dia

(mm)

Max. machinhg length

(mm)

Tooth width

( mm )

TMY3115CNC11

hobbing/chamfering/hobbing

4

150

20

250

5-60

Fully automated gear cutting and manufacturing of gear4 ktm:

1) Realize the processing of rough rolling, extruding edge, deburring and fine rolling in one clamping for small and medium module gears, and solves the problems of flanging burrs and bulges on the tooth surface completely. While significantly improving the machining accuracy, it avoids the reduction of tool life or machining accuracy caused by burr or bulge in the subsequent process after heat treatment.

2) The height of edge squeezing and deburring can be adjusted at will in the edging squeezing station, and the chamfering station can realize rapid production changed. At the same time, turning and deburring function can be selected with special design.

3) High running speed, accurate and reliable positioning,easy adjustment and operation by the built-in truss mechanical arm. Adopt multi-station circulating palleting automatic bin, which can quickly change production, easy adjustment, lifting height up to 400mm. One-time loading can meet the needs of long time machining.

4) Use fully enclosed stainless steel inner protection to get the dry cutting protection requirements. Separate the processing zone from the non-processing zone, and the large dip angle inner protection enables the chip to be quickly discharged out of the machine.

5) Adopt the modular design, and the functional components can be combined quickly according to customer needs to meet customized requirements.

Integrated CNC Chamfer Rolling and Deburring Unit with Two-Cut Hobbing Process for Burr-Free Flanks

Application

Suitable for the gear manufacturing of Passenger Vehicles, New Energy Vehicles, small and medium module Engineering Machinery Industry etc.

TOMAN Provide High Speed High Accuracy Gear Machinery and other Workpieces Solutions with Premium Quality Service to Global Users. Machines What We Supply: Gear Hobbing Machines, Spiral Bevel Gear Machines,Gear Shaving Machine,Gear Grinding Machines, Gear hobbers,CNC Machining Centers etc.

Video

Send your inquiry to this supplier