1 / 5

Free installation tyre to oil pyrolysis plant

| Model No. : | LN-2800-7200 |

|---|---|

| Brand Name : | Lanning |

| Certification : | Other |

Shangqiu, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- SGS Certification

Product description

Free installation tyre to oil pyrolysis plant

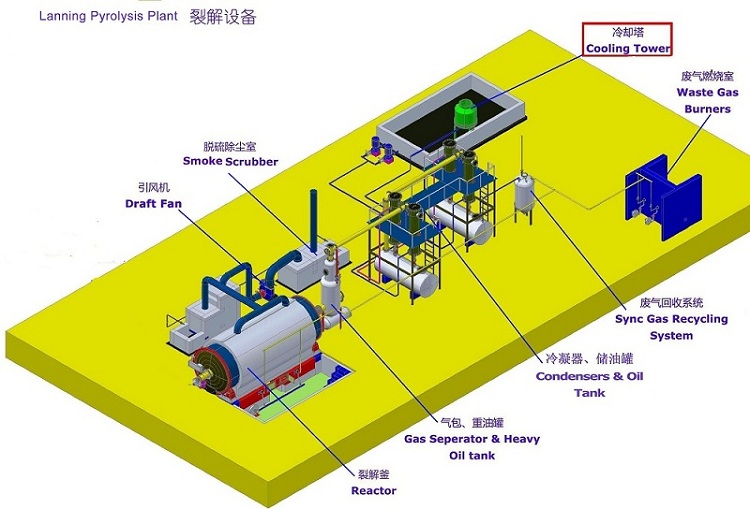

Pyrolysis process of tyre to oil pyrolysis plant

1,Feeding material,requires 1-2 hours,tire size less than 1.4meter can feed into reactor directly,bigger tire needs cutting first

,plastic can use auto feeder or conveyor belt to feed.

2, Heating ,needs 6-8 hours or so,as usual when reactor temperature reach up 180 degree,oil gas will start come out,when

temperature reach to 240 degree to 260 degree,a large amount of oil gas will come out.

3, Cooling, oil gas will go through cooling system,after cooling will become fuel oil.

4,Waste gas recycled,during the processing,except oil gas,there will be partly combustible but can not cooled gas,we called

waste gas,which can return to furnace for heating reactor so that can save fuel material.

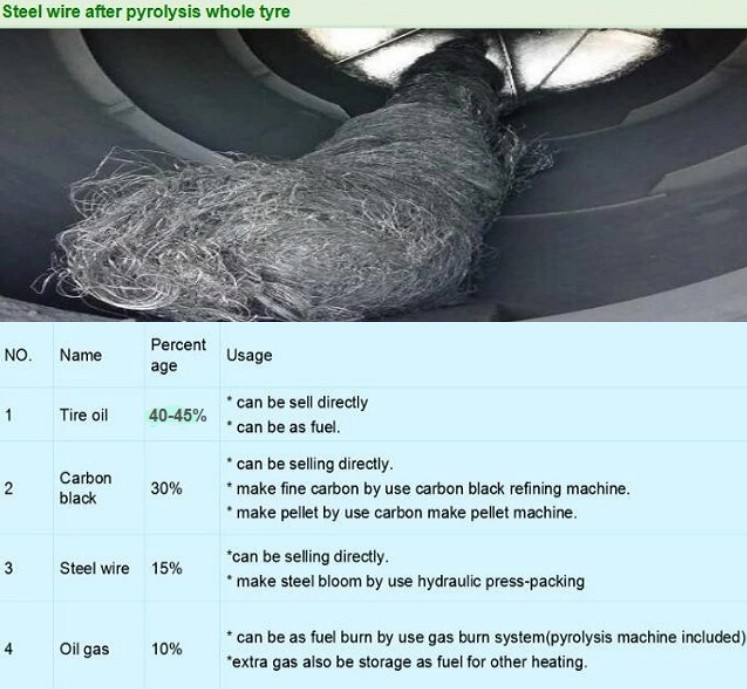

5, Carbon black and steel wire,in the end of processing,oil gas come out all,need discharge slag which contain carbon black

and steel wire.

Specifications of tyre to oil pyrolysis plant

|

NO. |

Raw materiaMol |

Note |

|

1 |

LN-2200*6600 |

5-6 TONS |

|

2 |

LN-2600*6600 |

7-8 TONS |

|

3 |

LN-2800*6600 |

10TONS |

|

4 |

LN-2800*7200 |

12TONS |

|

More specifications can make customized. |

||

Advantages of tyre to oil pyrolysis plant

Reactor:

1. The gear can be seperated from reactor, instead of welding on reactor. So it will not be destroyed by cycling heating.

and very easily to be re-placed

2. The reactor is supported in a centre line by rollers. It will remain stable while running.

3. Auto-welding, both inside and outside.

4. Made by special boiler plate Q245R/ Q345R. Security and long service life.

5. Made by rock wool insulation board. Save fuel and ensure heating effect.

6.Reactor for waste plastic recycling machine to oil add extra bigger locating ring.

Cooling system of waste plastic recycling machine to oil:

1. Coil pipe cooling system : there are 22-30 pipes lied in the water pond,each pipe 6 meters long, oil gas can be cooled in

larger area and longer time,thus get higher oil yield .

2. Vertical condensrs : we supply 4 cndensors, each has 44 pipes inside the condensors. Save land and

looks more neat and beautiful.

Anti-back fire device:

1. Little residual gas can not be cooled. It will recycle these gas to furnace burned to heat the reactor.

2. Water sealing disign will prevent tempering. Ensure safety.

Final products of tyre to oil pyrolysis plant

The machine can delivery within 15 working days after receiving deposit

Suitable container & shipping company will recommend to you to save shipping fee

Shangqiu, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- SGS Certification

Send your inquiry to this supplier